Heat storage device for transversely heating vertical coke exhaust coke oven

A heat storage device and coke oven technology, which is applied to the heating of coke ovens, coke ovens, and combustible gas heating coke ovens. The effect of simplifying structural relations and simplifying production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

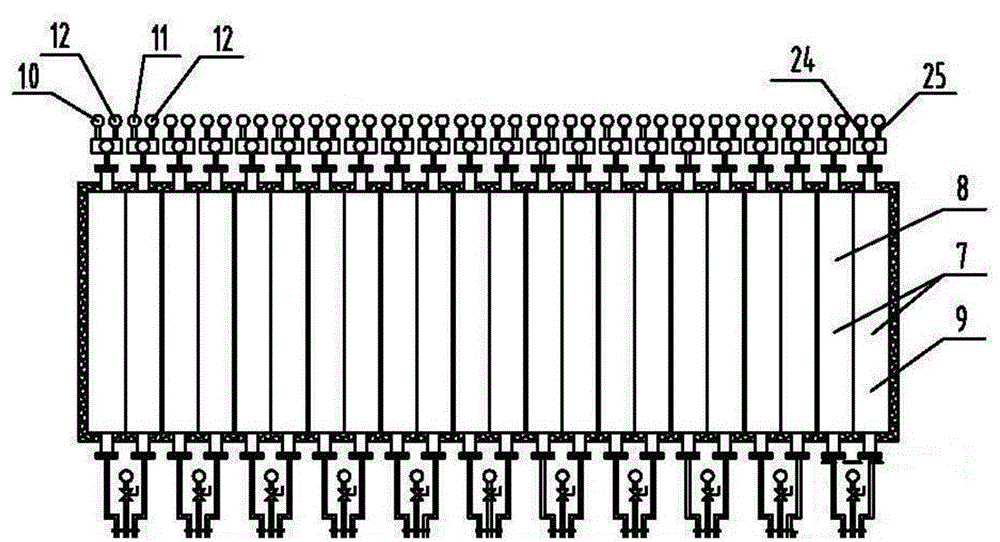

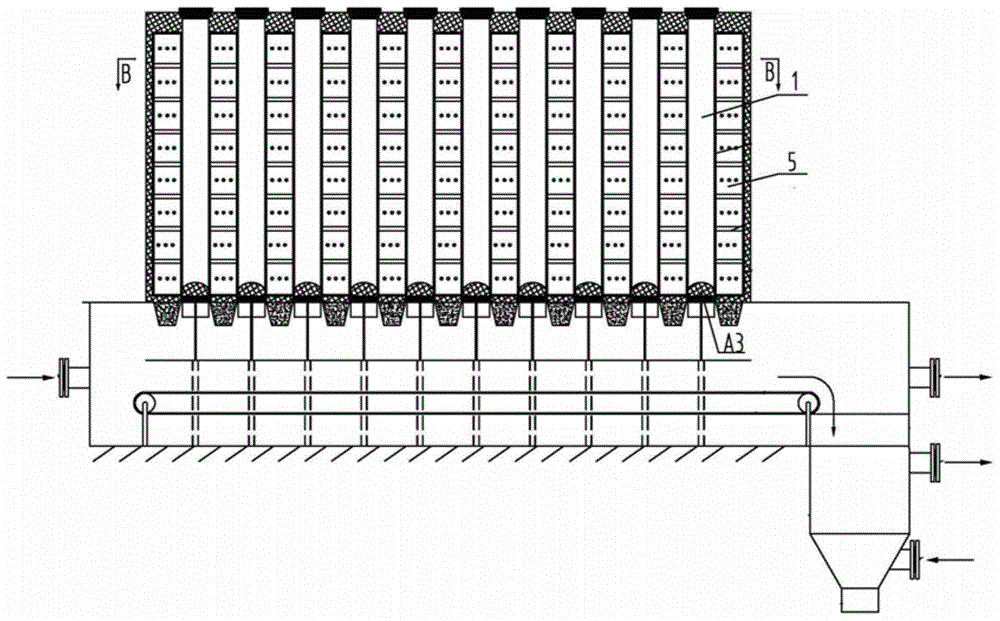

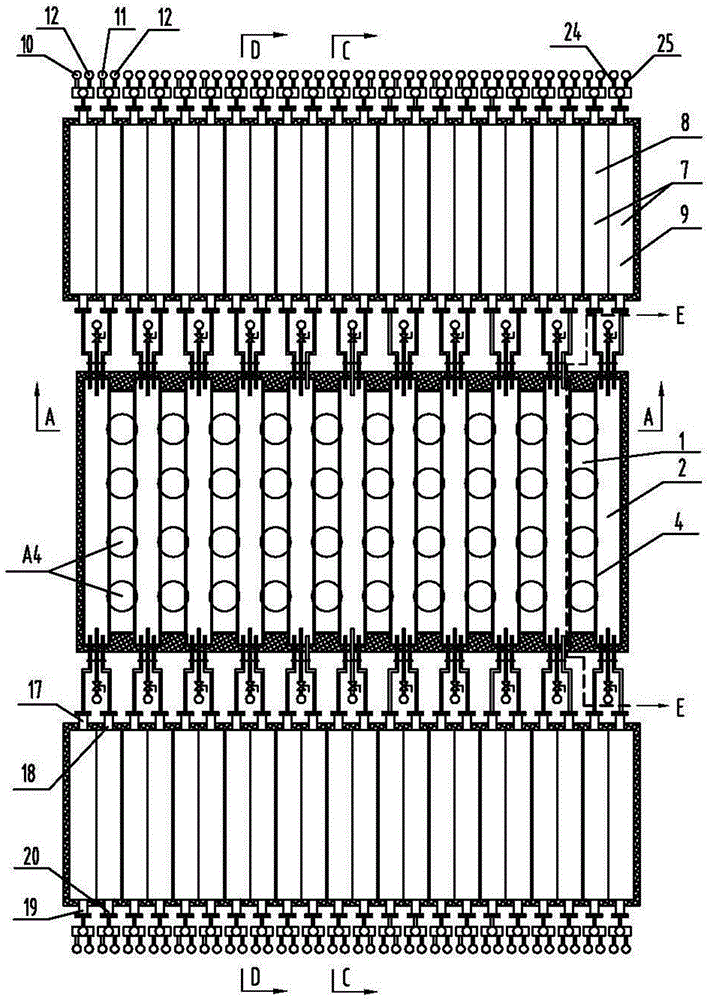

[0049] Such as Figure 1-7 As shown, a vertical coke-discharging coke oven with a coal charging hole A4 on the top is used (such as figure 2 , 3 ), the two sets of heat storage devices of the present invention are distributed on both sides of the coke oven (such as image 3 , 4 , 5), and are respectively connected to the ports on both sides of the coke oven combustion chamber 2, and the heating method is horizontal reciprocating heating (such as Figure 4 , 5 ).

[0050] The heating and heat storage process of this embodiment are as follows:

[0051] In a heating cycle, when lean gas is used for heating, lean gas and air are respectively passed from the lean gas standpipe 10 and the air standpipe 11 on one side, through the connecting pipe 24 with a reversing valve on the same side, and enter the same side. Lean coal gas heat exchange sub-channel 8 and air heat exchange sub-channel 9, in their respective heat exchange sub-channels, lean coal gas and air absorb the heat ...

Embodiment 2

[0056] Such as Figure 1-3 , 8, and 9, a vertical coke-discharging coke oven with a coal charging hole A4 on the top (such as figure 2 , 3 ), the two sets of heat storage devices of the present invention are distributed on both sides of the coke oven (such as image 3 , 8 , 9), and are respectively connected to the ports on both sides of the coke oven combustion chamber 2, and the heating method is horizontal alternate heating (such as Figure 8 , 9 ).

[0057] Compared with horizontal reciprocating heating, the heat storage device with the same structure is used, mainly because the structure of the combustion chamber of the two is different. The two adjacent upper and lower fire channels for horizontal alternate heating are called a double horizontal fire channel. , there are crossing holes and circulation holes on the partition brick between the two fire channels, the difference is as follows image 3 , 8 shown.

[0058] The heating and heat storage process of this ...

Embodiment 3

[0067] The heat storage device is distributed on one side of the vertical coke-discharging coke oven, and the other side is a tamping coal loading car, such as Figure 10 , 11 As shown, the coking adopts the method of side entry and bottom exit, and horizontal alternate heating.

[0068] Such as Figure 10 , 11 As shown, the right side of the carbonization chamber 1 has a side furnace door A14, and the tamping coal charging car 6 is charged to the carbonization chamber 1 through the side furnace door A14. A group of heat storage devices of the present invention are arranged on the left side of the coke oven. It is also connected to the left port of coke oven combustion chamber 2, and the heating method is horizontal alternate heating (such as Figure 10 ).

[0069] Obviously, compared with the horizontal reciprocating heating, the heat storage device with the same structure is mainly due to the difference in the structure of the two combustion chambers. The horizontal alte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com