Steam heating type cooking utensil

A cooking utensil and heating technology, applied in the field of kitchen appliances, can solve the problems of high temperature, heavy and unsightly body, sticking to the pot, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

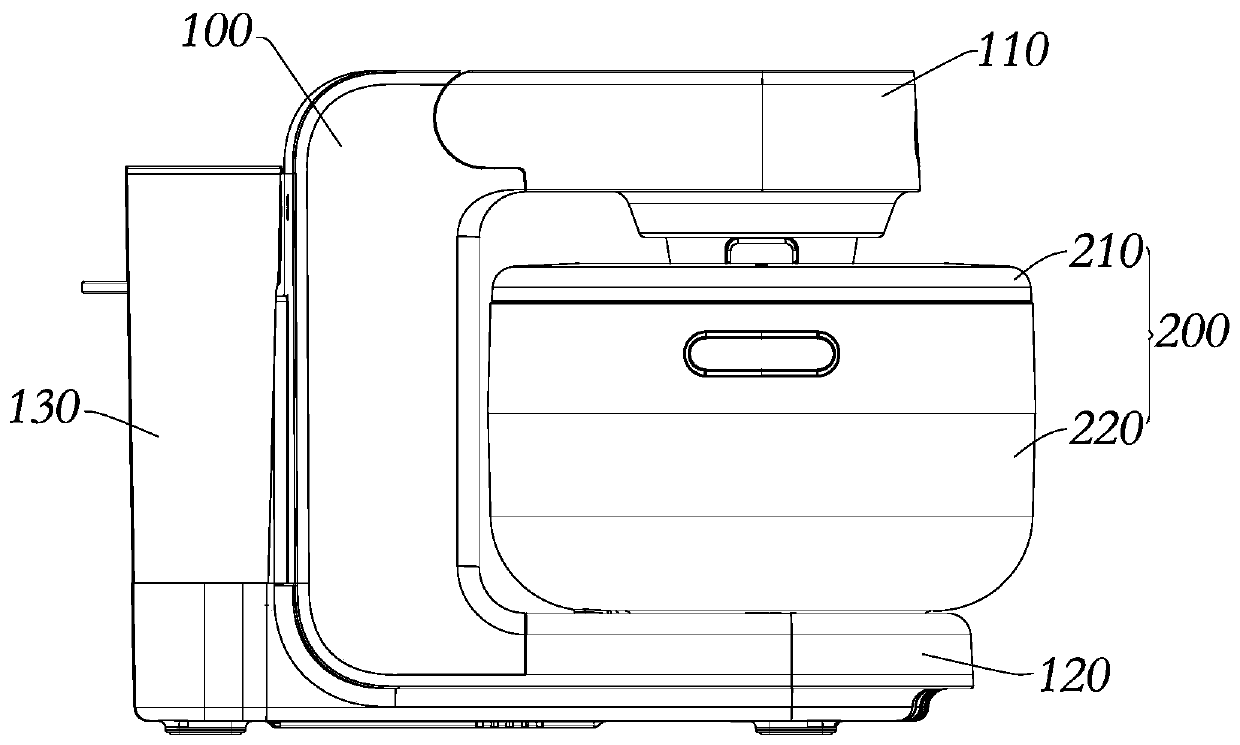

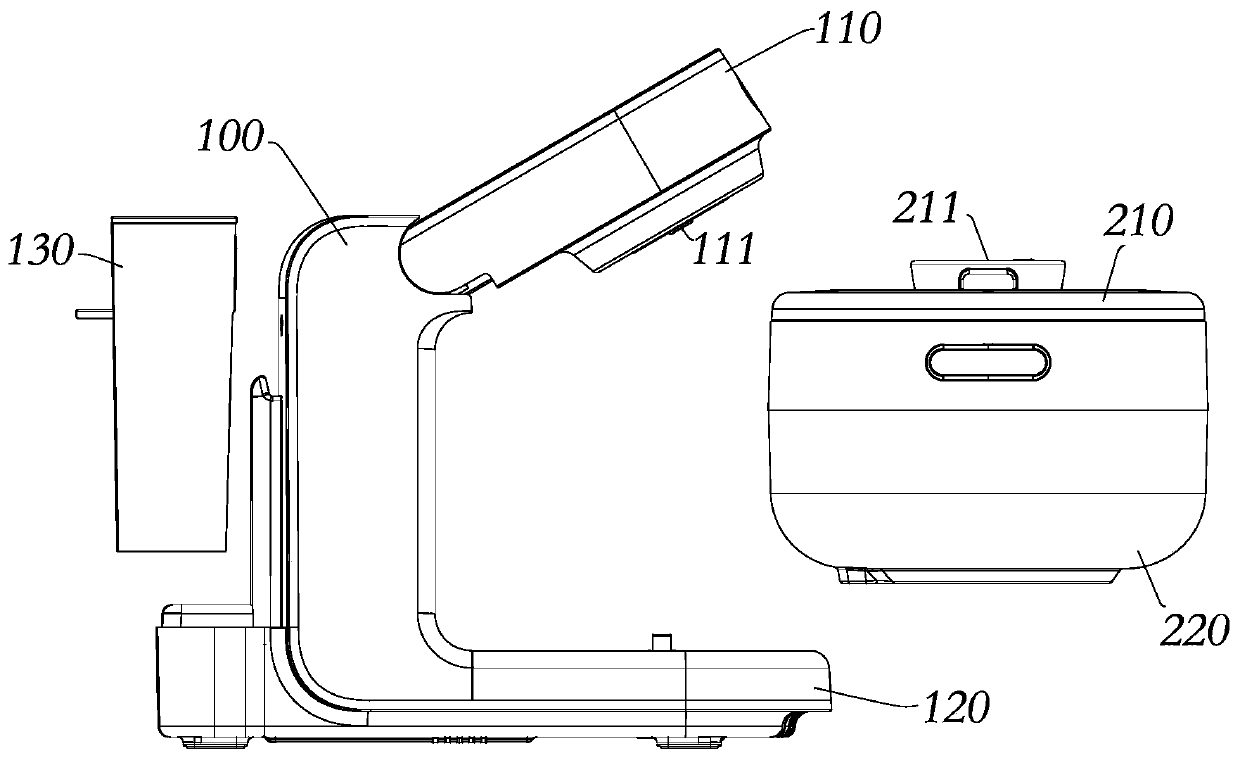

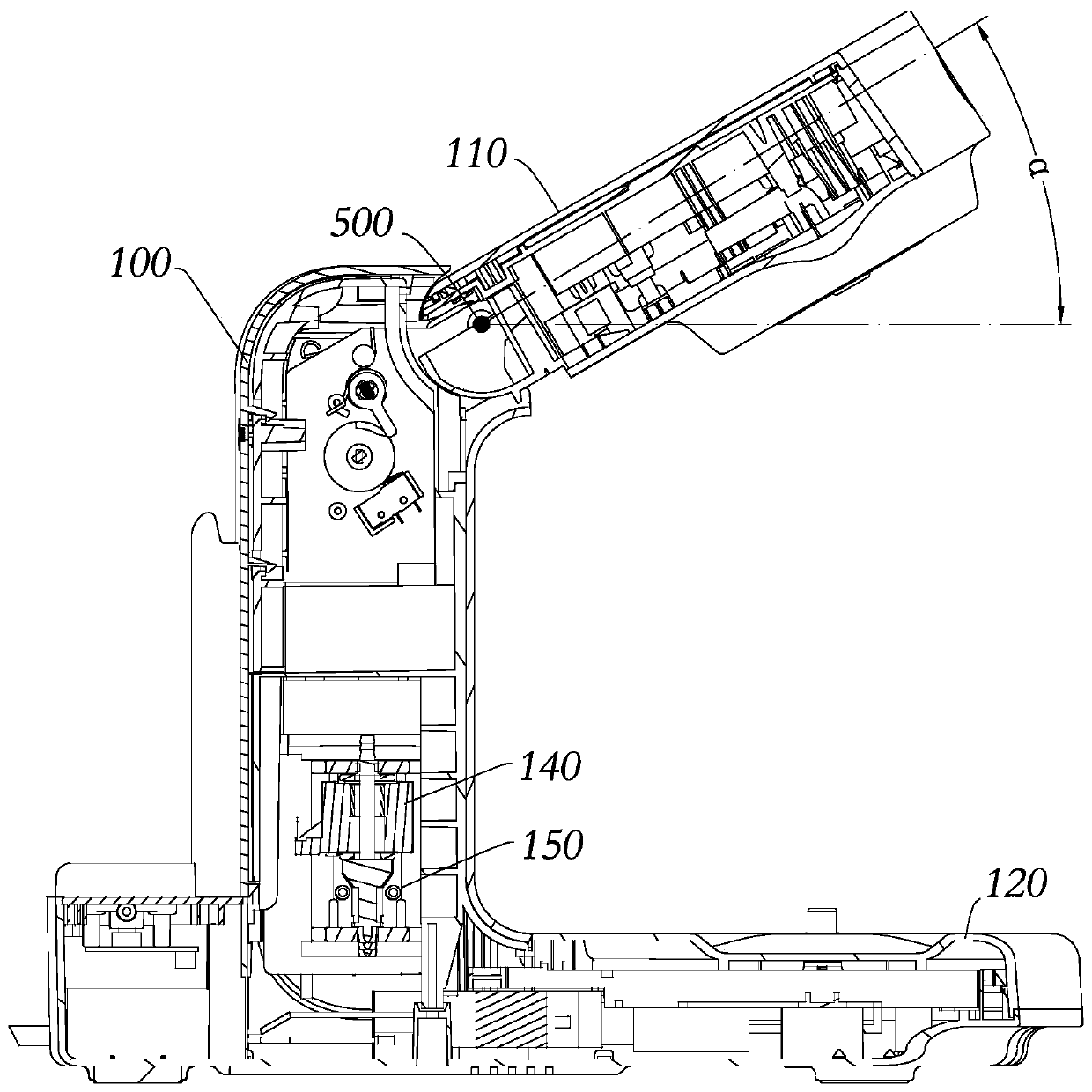

[0058] refer to Figure 1-3 , the steam heating cooking utensil proposed in Embodiment 1 of the present invention includes a body 100 and a pot 200, a machine head 110 is arranged on the upper part of the body 100, a bearing platform 120 is arranged on the lower part of the body 100, and the cooking utensil 200 is placed on the bearing platform 120. An open space for accommodating the pot 200 is formed between the head 110 and the carrying platform 120, and the machine head 110 and the body 100 are connected by a rotation limiting device, which limits the machine head 110 to the first position where the pot 200 is docked. And switch between the second station separated from the pot 200.

[0059] Specifically: the body 100 of this embodiment is provided with a steam generator 150 (such as: a water storage boiler, an instant boiler, etc.) and a water pump 140, and a water tank 130 is set on one side of the body 100, and the water pump 140 works to pump the water in the water tan...

Embodiment approach

[0066] combine Figure 4 , 5 The rotation limiting device includes a limiting plate 300 installed on the machine head 110 and a fixed bracket 400 installed on the body 100. The fixed bracket 400 is provided with a limiting shaft 410, and the limiting plate 300 is provided with a limiting hole 310. The positioning hole 310 has a first limiting end and a second limiting end. When the limiting shaft 410 moves to the first limiting end, it defines the first station and can be locked at the first limiting end. The limiting shaft 410 moves to The second limit end defines the second station. Specifically: the machine head 110 includes a machine head upper cover 112 and a machine head lower cover 113, one end of the stop plate 300 is fixedly installed on the machine head lower cover 113, and the other end of the stop plate 300 is provided with an arc-shaped stop hole 310, The limit hole 310 includes a guide segment 312 of equal width and a limit segment 311 wider than the guide segm...

Embodiment 2

[0080] refer to Figure 10 , 11 , different from Embodiment 1, the solution of this embodiment changes the locking and unlocking methods of the limit shaft 410, specifically:

[0081] The rotation limiting device includes a limiting plate 300 and a fixed bracket 400. One end of the limiting plate 300 is fixedly mounted on the lower cover 113 of the machine head, and the other end of the limiting plate 300 is provided with a limiting hole 310. The limiting hole 310 includes a vertical section 314 And the horizontal section 313 extending horizontally from the bottom of the vertical section 314, the upper end of the vertical section 314 is the second limiting end, and the horizontal section 313 forms the first limiting end. The rotating shaft 500 is fixed on the limiting plate 300 through integral injection molding or other methods, and the two ends of the rotating shaft 500 are rotatably limited on the lower cover 113 of the machine head. One end of the limiting shaft 410 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com