Vacuum cleaner

A vacuum cleaner and ventilator technology, applied in the direction of vacuum cleaners, suction filters, suction nozzles, etc., can solve the problems of high-pressure head loss of connecting pipes, unfavorable aerodynamic performance of vacuum cleaners, etc., and achieve the effect of improving aerodynamic performance and reducing pressure head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

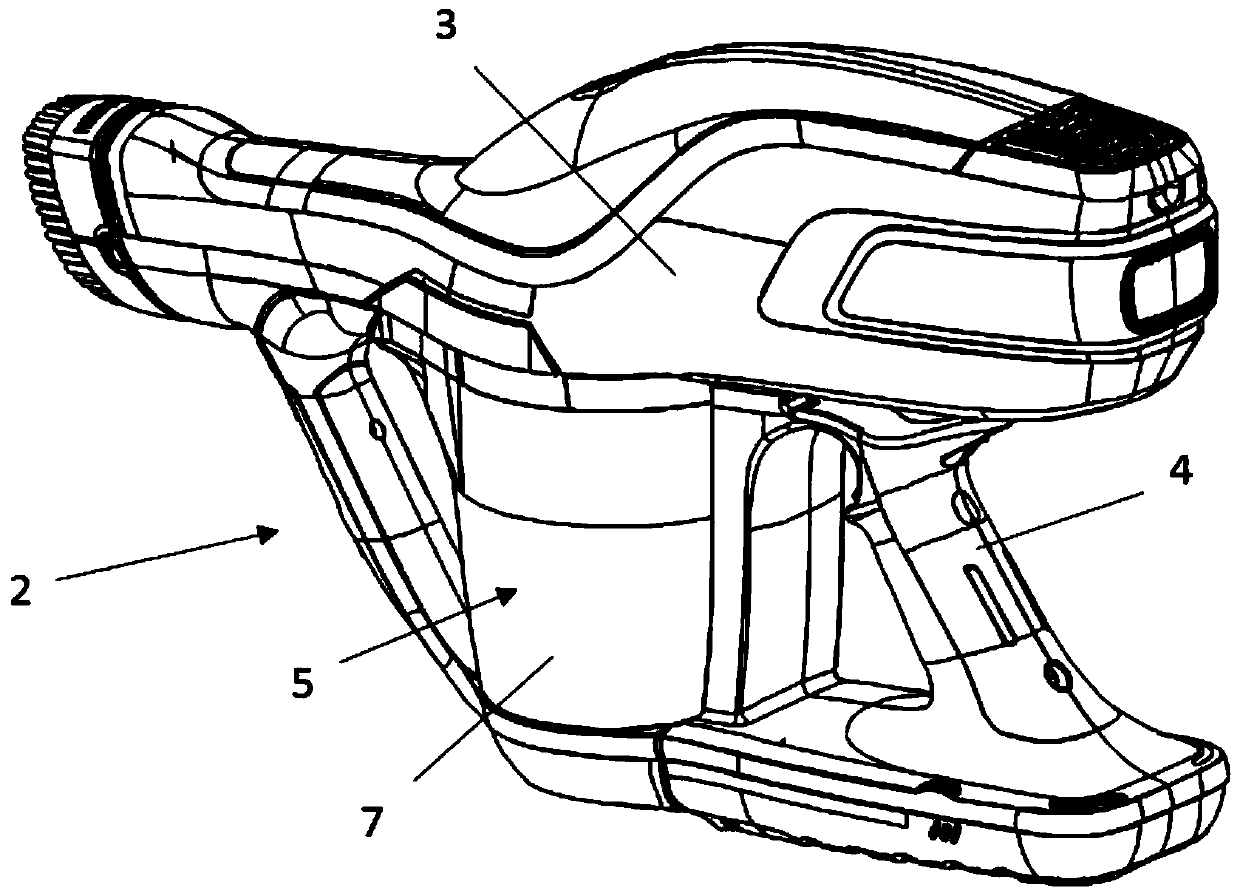

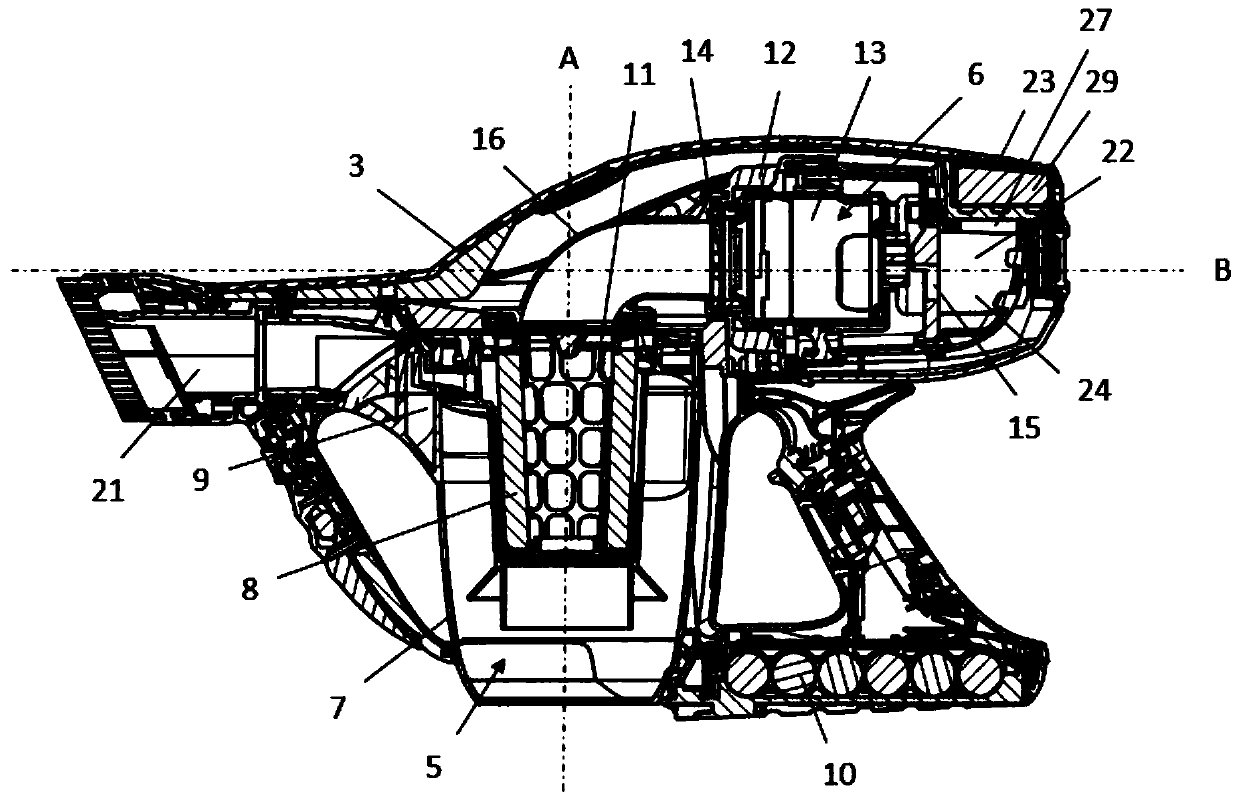

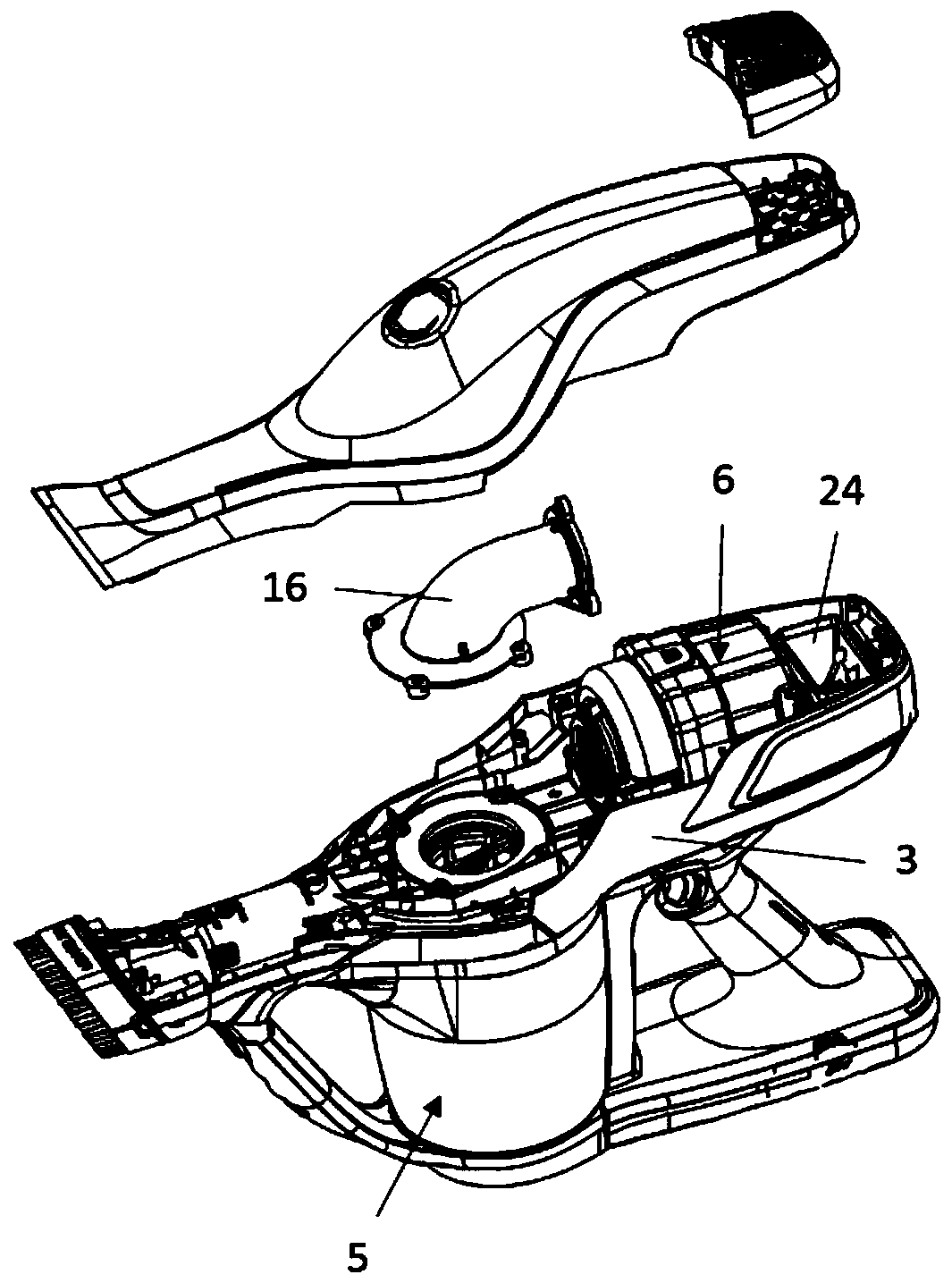

[0053] Figure 1 to Figure 7 Shown is a vacuum cleaner 2, and more particularly a portable vacuum cleaner, comprising: a main body 3 equipped with a grip handle 4, a waste separation device 5 removably mounted on the main body 3, and a body 3 accommodated in the main body 3 Inhalation device 6 in .

[0054] The waste separation device 5 is advantageously of the cyclone type and comprises in particular a waste storage container 7 and a separation filter 8 housed in the waste storage container 7 . The waste storage container 7 more specifically comprises an air inlet opening 9 and an air outlet hole 11 .

[0055] like Image 6 As shown, the suction device 6 comprises a motor housing 12 and an electric ventilator 13 arranged in the motor housing 12, which is also referred to as a suction motor. In a known manner, the motor-driven ventilator 13 comprises a ventilator and an electric motor which causes the ventilator to be driven in rotation.

[0056] according to Figure 1 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com