Fluid distributor

A fluid distributor and fluid technology, which is applied to heat exchanger shells, lighting and heating equipment, heat exchange equipment, etc., can solve the problems of low heat exchange efficiency of heat exchangers, uneven distribution of distributors, etc., and improve heat exchange efficiency , Smooth flow and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

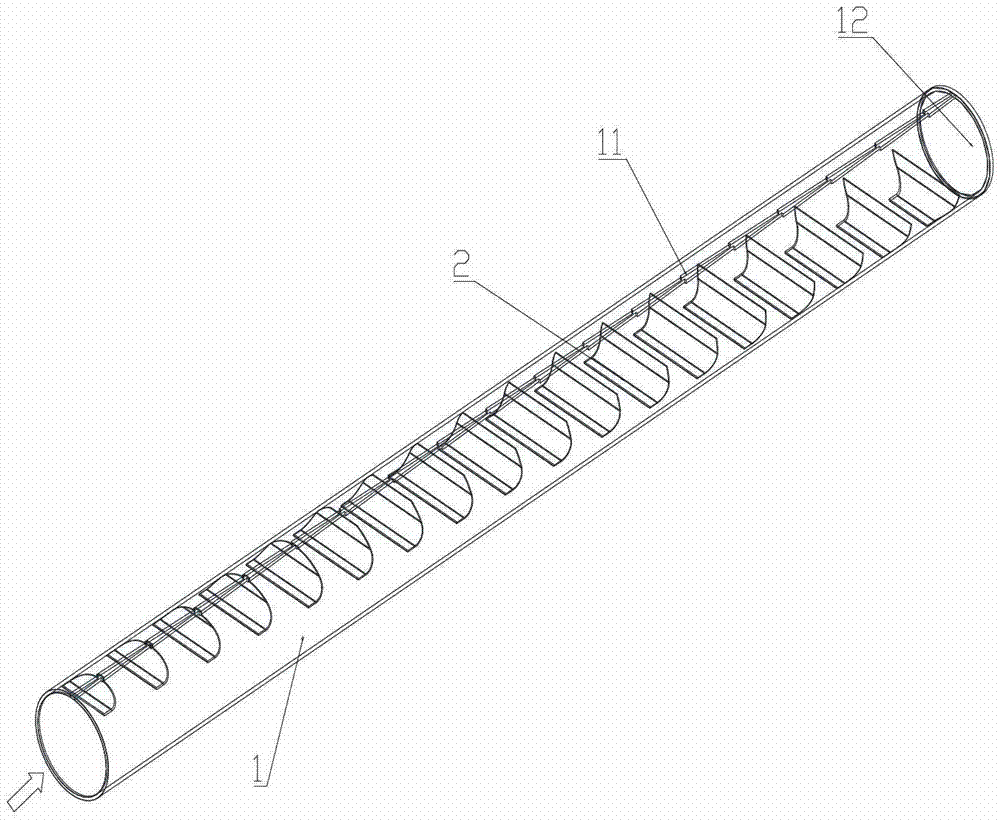

[0031] like figure 1 Shown is a fluid distributor disclosed by the present invention, which is arranged in the main fluid pipe, and is used to distribute the incoming fluid more evenly into the branch pipes.

[0032] The fluid distributor includes a distribution pipe body 1 adapted to the shape of the fluid main pipe, a distribution groove 11 is formed on the pipe wall of the distribution pipe body 1, and a sealing plate 12 is provided at the end of the distribution pipe body 1; The deflector 2 inside the pipe body 1, the deflector 2 is formed by connecting the inflow plate 21 and the outflow plate 22 with a transition arc plate in the middle, and the surface of the inflow plate 21 is along the distribution pipe body 1 The direction of the inlet of the outlet plate 21 extends along the direction of the distribution groove 11; the deflectors 2 are arranged in sequence along the length direction of the distribution pipe body 1, and the inflow plate 21 is Stepwise arrangement an...

Embodiment 2

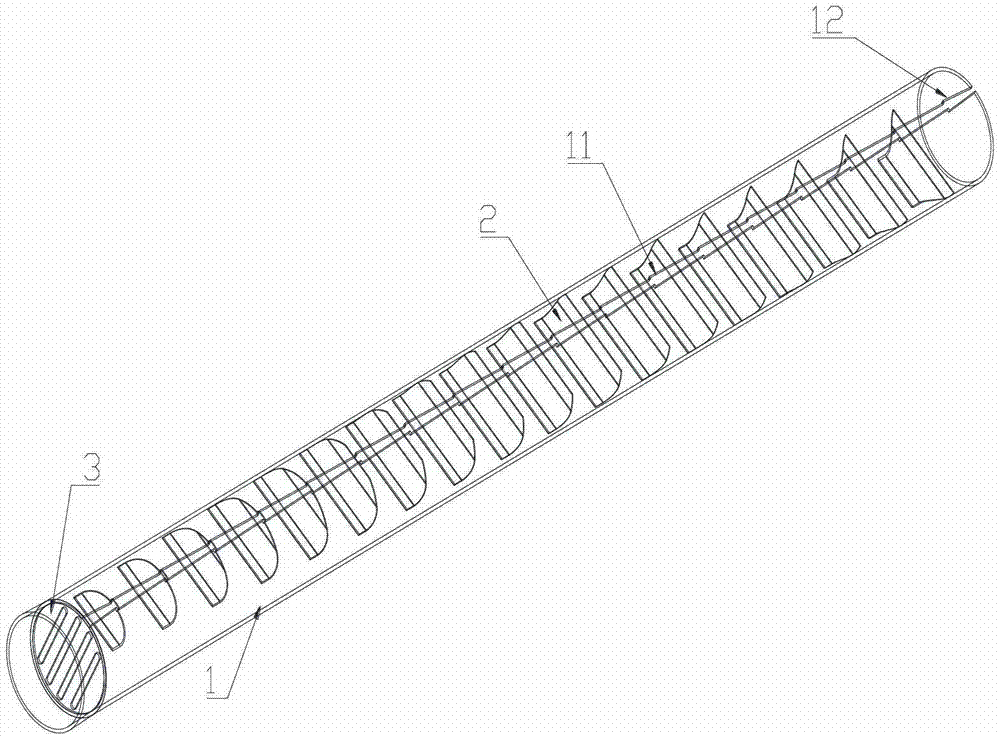

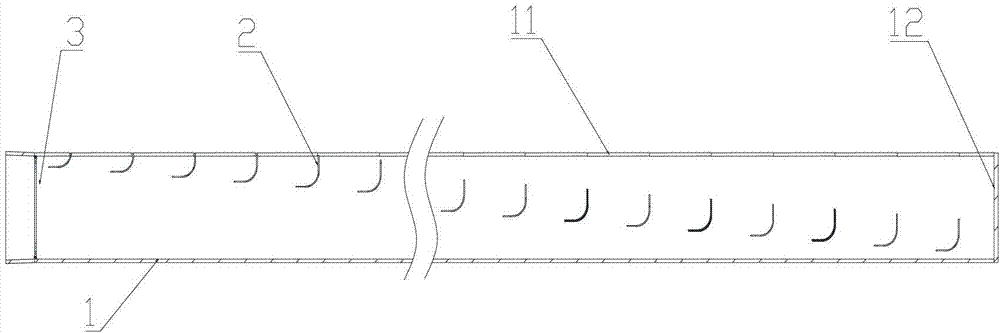

[0038] The structure of the fluid distribution pipe of this embodiment is roughly the same as that of the fluid distribution pipe of Embodiment 1, the difference lies in: in this embodiment, as figure 2 , image 3 As shown, the inlet side of the distribution pipe body 1 is provided with a flow equalizer 3 along the cross-sectional direction of the distribution pipe body 1 . Several equalizing grooves 31 are formed on the said equalizing plate 3, such as Figure 4 As shown, the widths of the equalizing grooves 31 are equal. The difference in length is less than 25%.

[0039]The length direction of the flow equalizing groove 31 is perpendicular to the direction of the plate surface of the inflow plate 21 , and the fluid is uniformly distributed on the inflow plate 21 after passing through the flow equalizing groove 31 .

[0040] In other implementations, such as Figure 5 As shown, the deflector 2 is formed with several partitions 23 along the fluid inflow direction, and th...

other Embodiment approach

[0041] In other embodiments, the angle between the inflow plate 21 and the outflow plate 22 is any angle between 80-120 degrees, which can realize the effect of equalizing the flow of the distribution pipe.

[0042] In addition, in other embodiments, the distribution groove 11 may also be a helical line along the length direction of the distribution pipe body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com