Corrosion-free energy saving chimney

A chimney and flue gas technology, applied in the field of chimneys, can solve problems such as difficult construction, increased resistance to rising of flue gas, increased pressure loss, etc., and achieve convenient and simple construction operation process, increase initial speed and power, and diversion effect Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

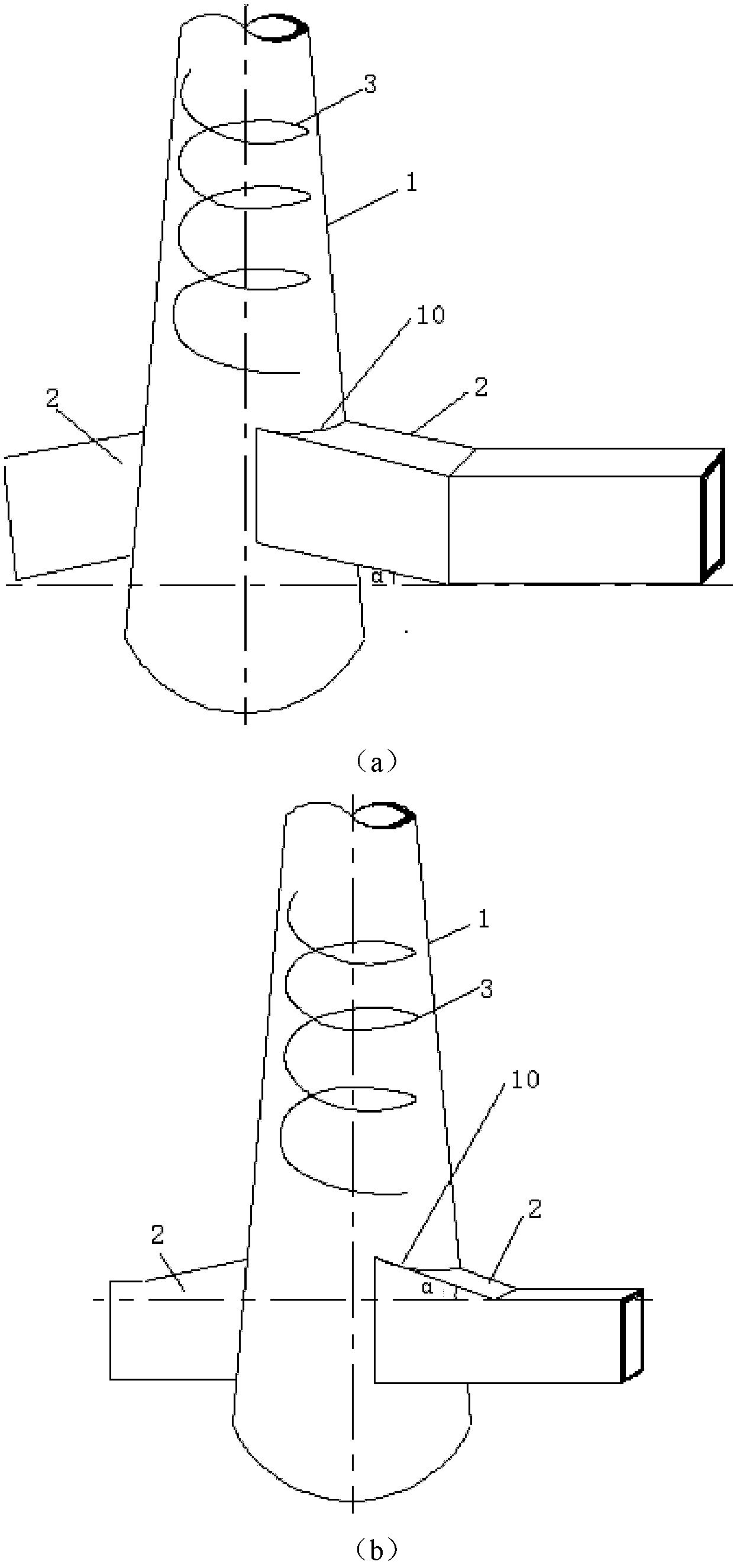

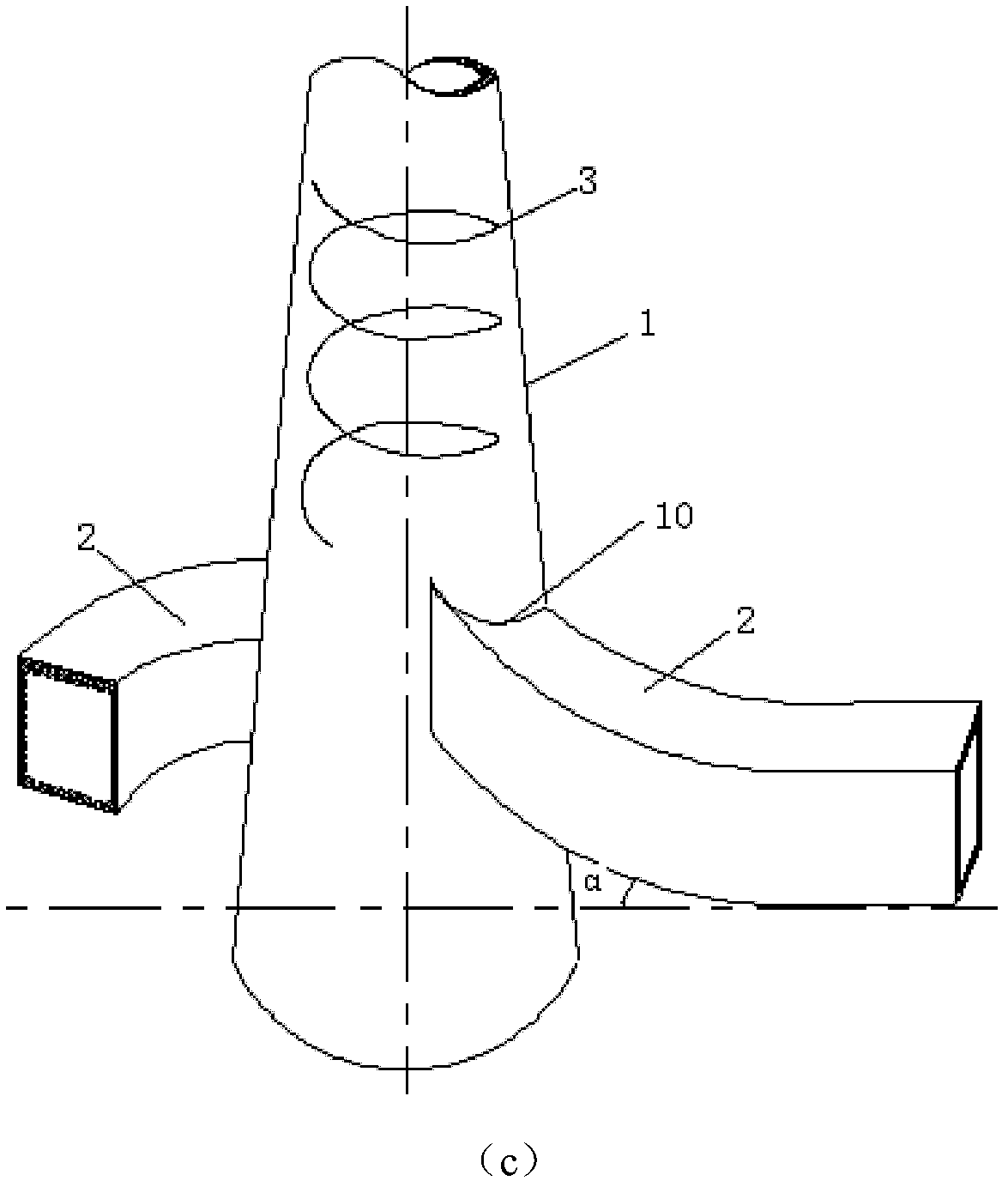

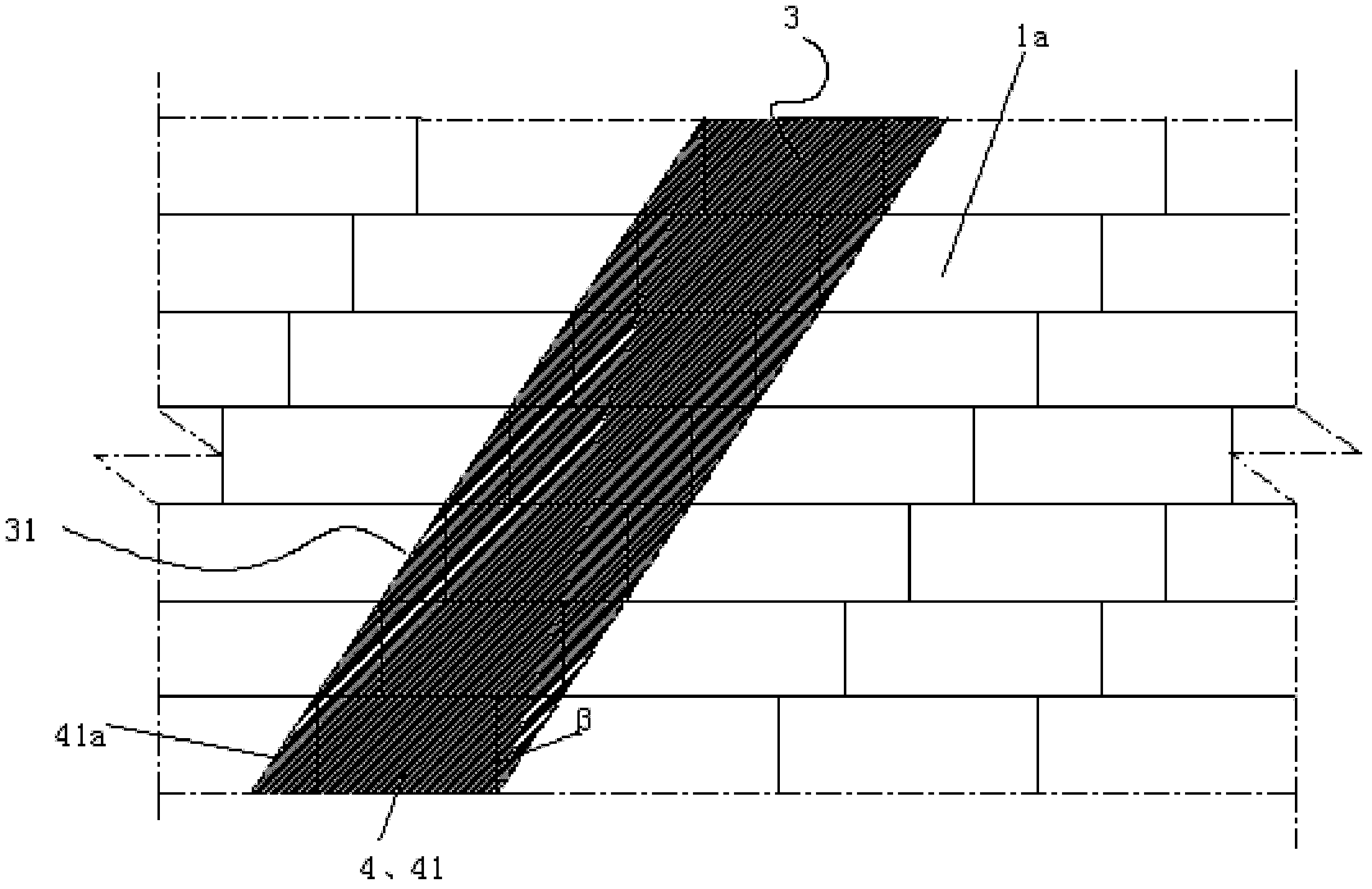

[0040] Such as figure 1As shown in the schematic diagram of the overall structure of the non-corrosion energy-saving chimney of the present invention, the non-corrosion energy-saving chimney of the present invention includes a chimney cylinder 1, a spiral flue gas guide line 3 is provided on its inner lining 1a, and a tube wall at its lower end is provided with The smoke inlet 10; the flue inlet 2, one end of which is connected to the smoke inlet 10, communicates with the inside of the chimney cylinder through the smoke inlet 10; wherein, the spiral flue gas guide line 3 has a guide part 41 in multiple pieces The blocks are stacked by 4, such as figure 2 As shown, the guide portion 41 of each block 4 has a smooth inclined surface 41a so that the inclined surfaces of all the stacked blocks are smoothly connected, thereby forming the guide surface 31 for making the smoke rise in a rotating manner.

[0041] Such as figure 2 As shown, the spiral flue gas guide line 3 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com