An automatic painting device for stainless steel mesh processing

A technology of stainless steel mesh and paint spray gun, which is applied in spraying devices, paint spray booths, and devices for coating liquid on the surface. and other problems, to achieve the effect of improving the efficiency of spray painting processing, high degree of automation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

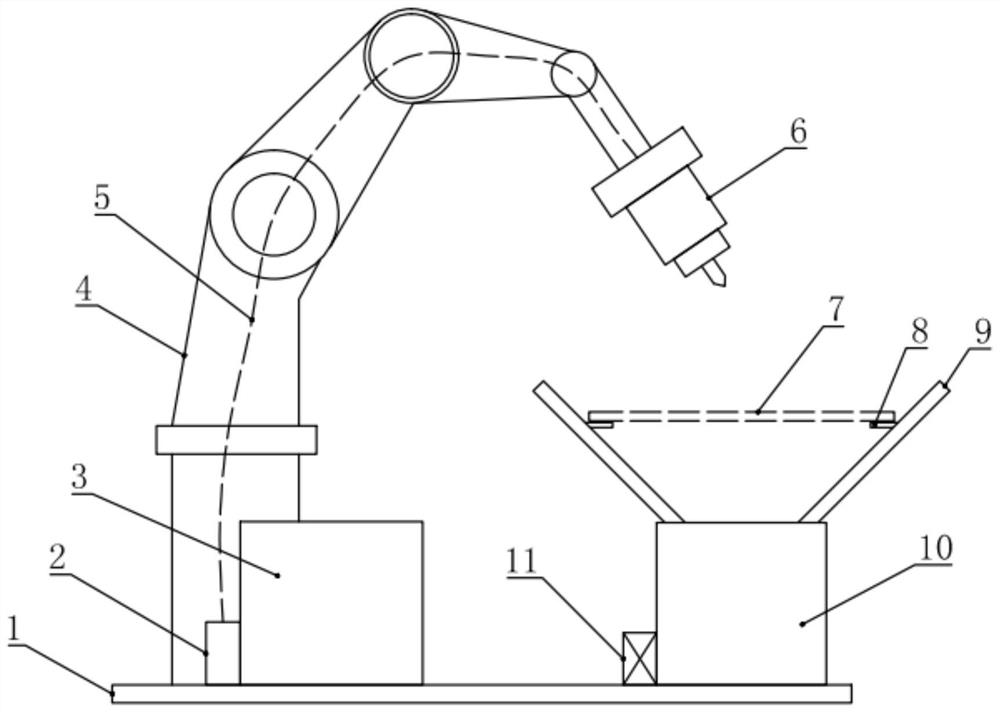

[0018] see Figure 1-2 , in an embodiment of the present invention, an automatic painting device for stainless steel mesh processing, including a mounting base 1, a manipulator 4, a paint storage box 3 and a support box 10 are respectively installed on the mounting base 1, and the end of the manipulator 4 Paint spray gun 6 is installed, and paint spray gun 6 is connected with the outlet of delivery pump 2 by paint delivery pipe 5, and delivery pump 2 is installed on the paint storage box 3, and the entrance of delivery pump 2 communicates with the inner chamber bottom of storage paint box 3; The top of the support box 10 is installed with a plurality of slanting tubes 9 distributed in the circumferential direction, and the upper side of the slanting tubes 9 is slidably provided with a support block 8 for carrying the stainless steel mesh 7, and the inner side of the support box 10 is provided with a In order to drive all the supporting blocks 8 to move along the slanting tubes...

Embodiment 2

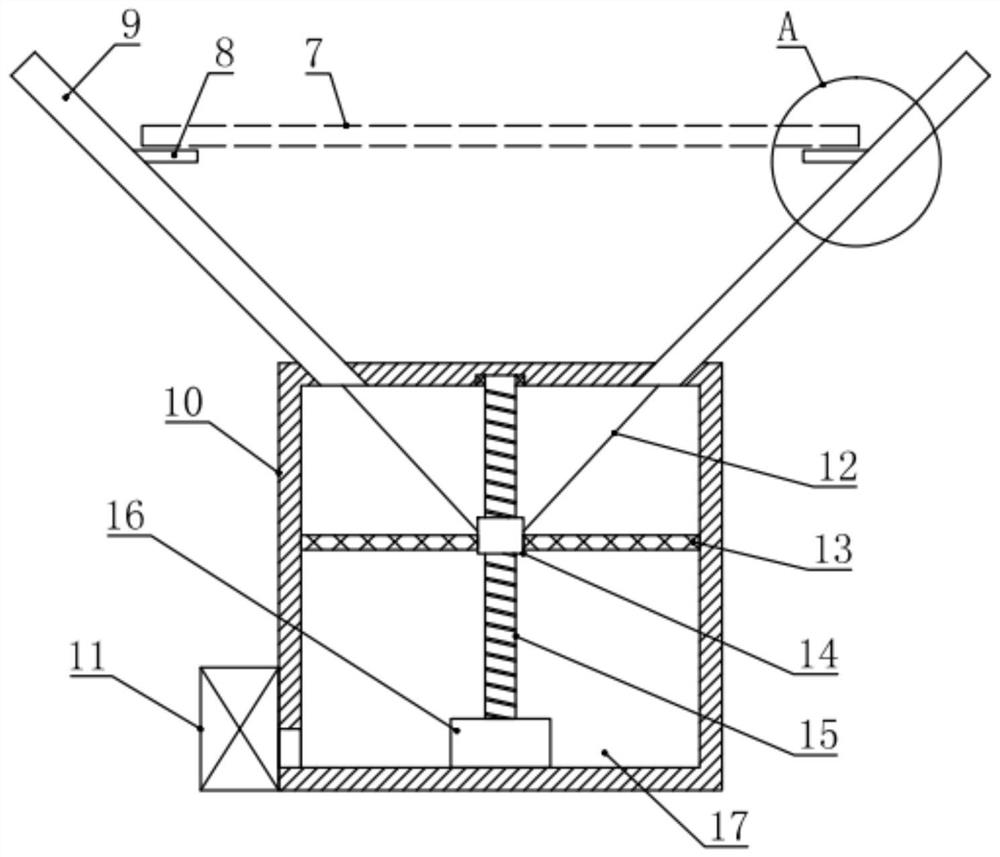

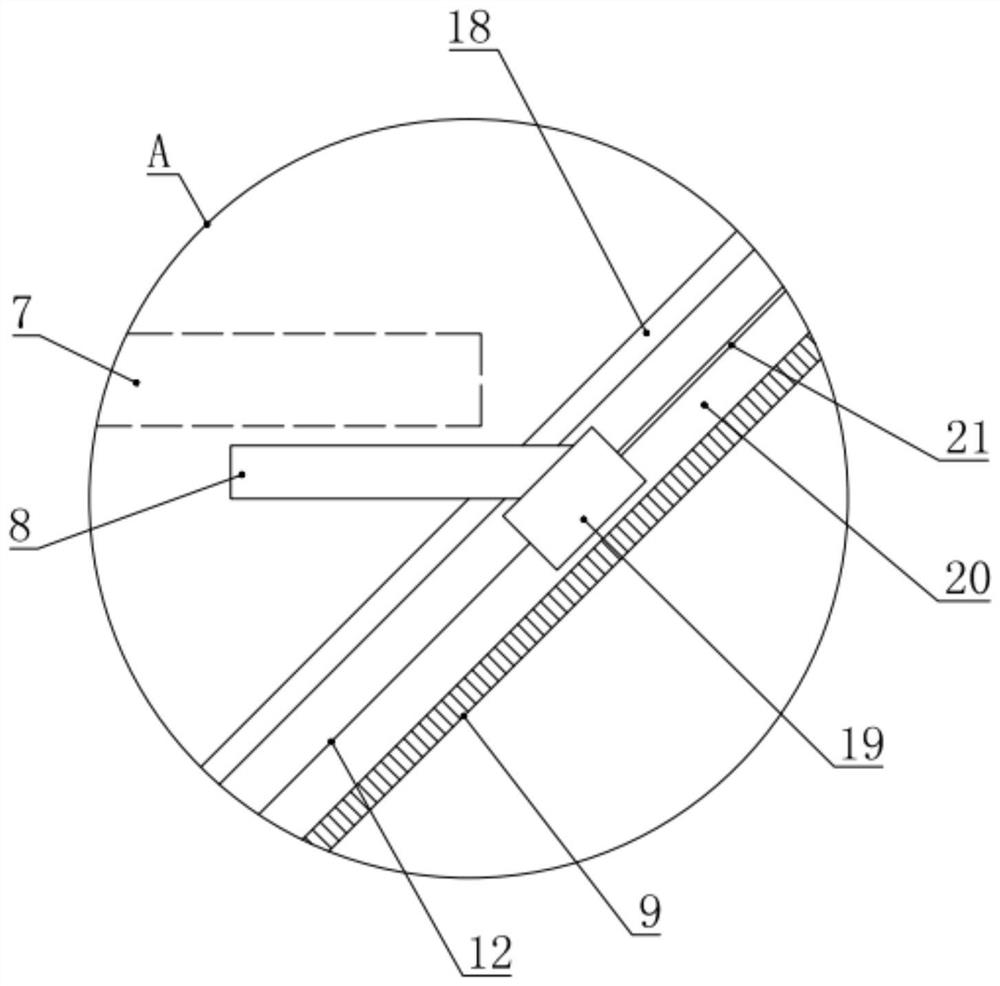

[0021] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

[0022] In this embodiment, the drive assembly includes a pull cord 12, a threaded sleeve 14, a threaded rod 15, a rotating motor 16, a slider 19 and an elastic cord 21, and the inner cavity of the support box 10 is a cavity 17, and the diagonal brace The inner side of the tube 9 is provided with a slider cavity 20, the lower end of the slider cavity 20 communicates with the top of the cavity 17, the slider cavity 20 is provided with a slider 19 for sliding, the support block 8 is horizontally arranged, and one end of the support block 8 It is fixedly connected with the slider 19, the slanting tube 9 is also provided with a movable opening 18 for the movement of the support block 8, the upper end of the slider 19 is connected with an elastic rope 21, and the upper end of the elastic rope 21 is connected and fixed to the slider The top of the cavity 20; the middle part of the cavity 17 is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com