Oil production ore filtering device

A filter device and oil extraction technology, applied in the field of machinery, can solve problems affecting pipeline branching and auxiliary treatment operations, sand and gravel solid plugging, oil soaking, etc., to achieve the effect of improving waste reuse value, uniform fluid quality, and convenient delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

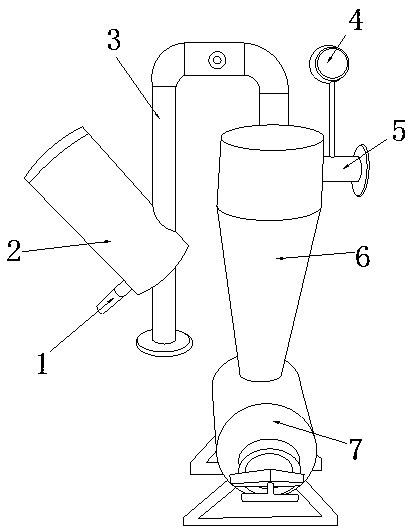

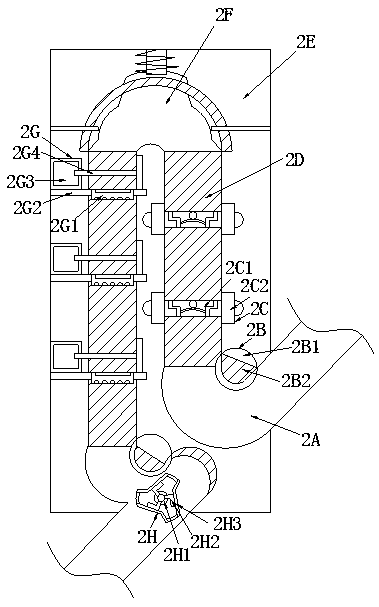

[0033] see Figure 1-Figure 6, the present invention provides a kind of sand and gravel filter device for petroleum exploitation, its structure comprises: slag discharge pipe 1, sieve plate sliding sand filter 2, petroleum delivery pipe 3, pressure gauge 4, drainage pipe 5, recoil spin filter tank 6, Stamping horizontal tank 7, the sieve tray sliding sand filter 2 and the oil delivery pipe 3 are nested into one body and communicate with each other, the slag discharge pipe 1 is inserted in the lower left corner of the sieve tray sliding sand filter 2 and are perpendicular to each other, The oil delivery pipe 3 is inserted in the upper left corner of the backflush spin filter tank 6 and communicates with each other. The backflush spin filter tank 6 is inserted on the top of the stamping horizontal tank 7 and the axes are collinear. The pressure gauge 4. It is installed on the top of the drainage pipe 5 and is on the same vertical plane. The drainage pipe 5 is inserted in the upp...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a kind of sand and gravel filtering device for oil exploitation, other respects are identical with embodiment 1, and difference is:

[0041] see figure 2 , the rotating paddle disk 2H is composed of a fin shaft wheel 2H1, a support column block 2H2, and a folding groove turntable 2H3. The fin shaft wheel 2H1 and the support column block 2H2 are nested into one body, and the support column The block 2H2 and the folding groove turntable 2H3 adopt an interference fit and are on the same vertical surface, and the support column block 2H2 top brushes the folding groove turntable 2H3 to form an overall baffle backwashing and dialysis oil stain effect to purify the quality of petroleum.

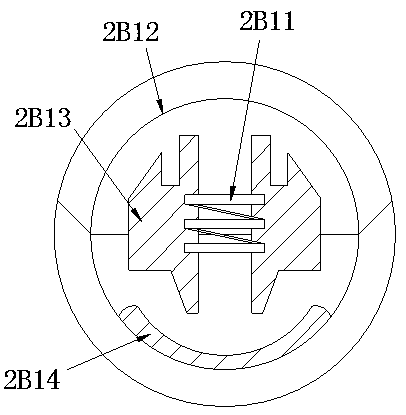

[0042] see Figure 6 , the fin shaft wheel 2H1 is composed of a fin plate 2H11, a buckle block 2H12, a thick shaft wheel 2H13, and a gasket frame ring 2H14, and the fin plate 2H11 is closely attached to the buckle block 2H12, so The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap