Pressing type multi-class central curve track control mechanism

A technology of curve trajectory and control mechanism, which is applied to non-circular curve plotters, manufacturing tools, metal processing machinery parts, etc., can solve the problems of insufficient curve accuracy and few types of concentric curves, and achieve accurate curves formed by trajectory changes , suitable for a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described in detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

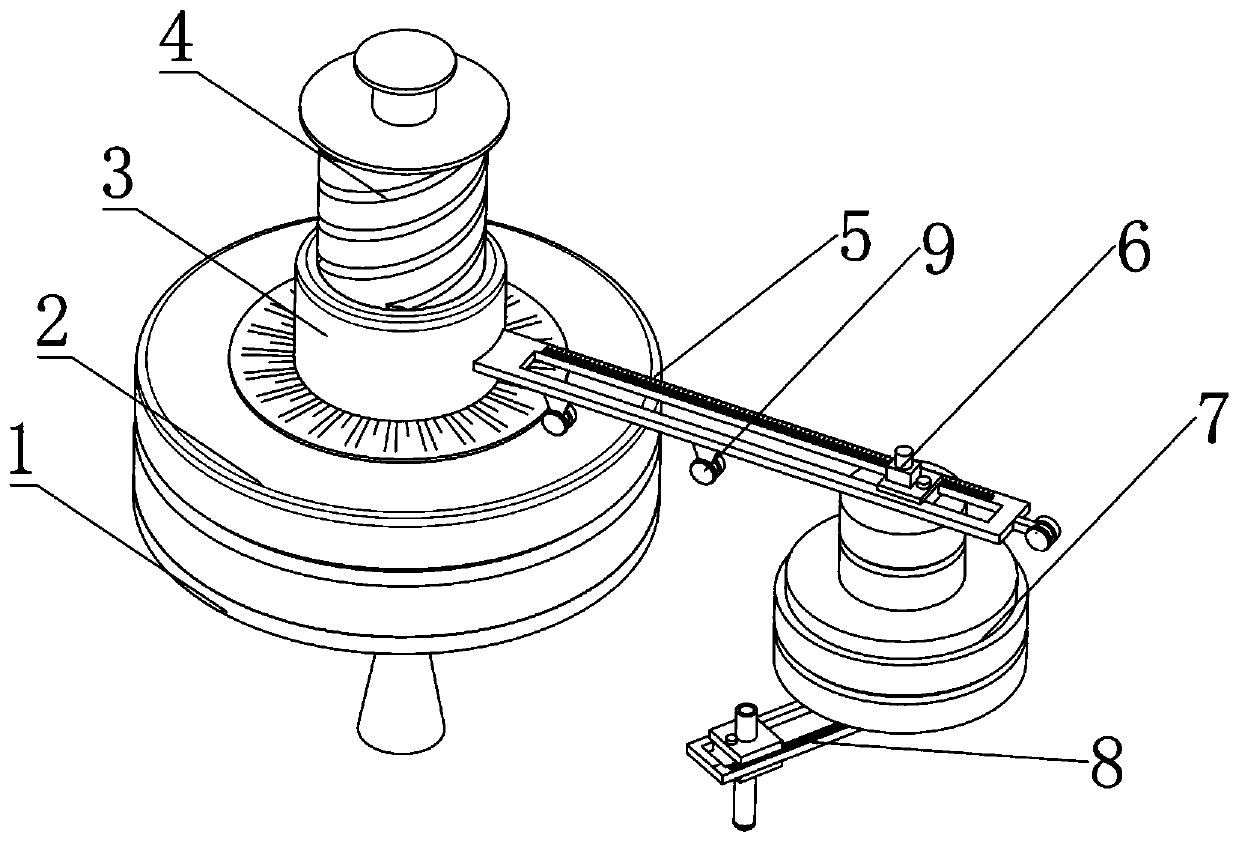

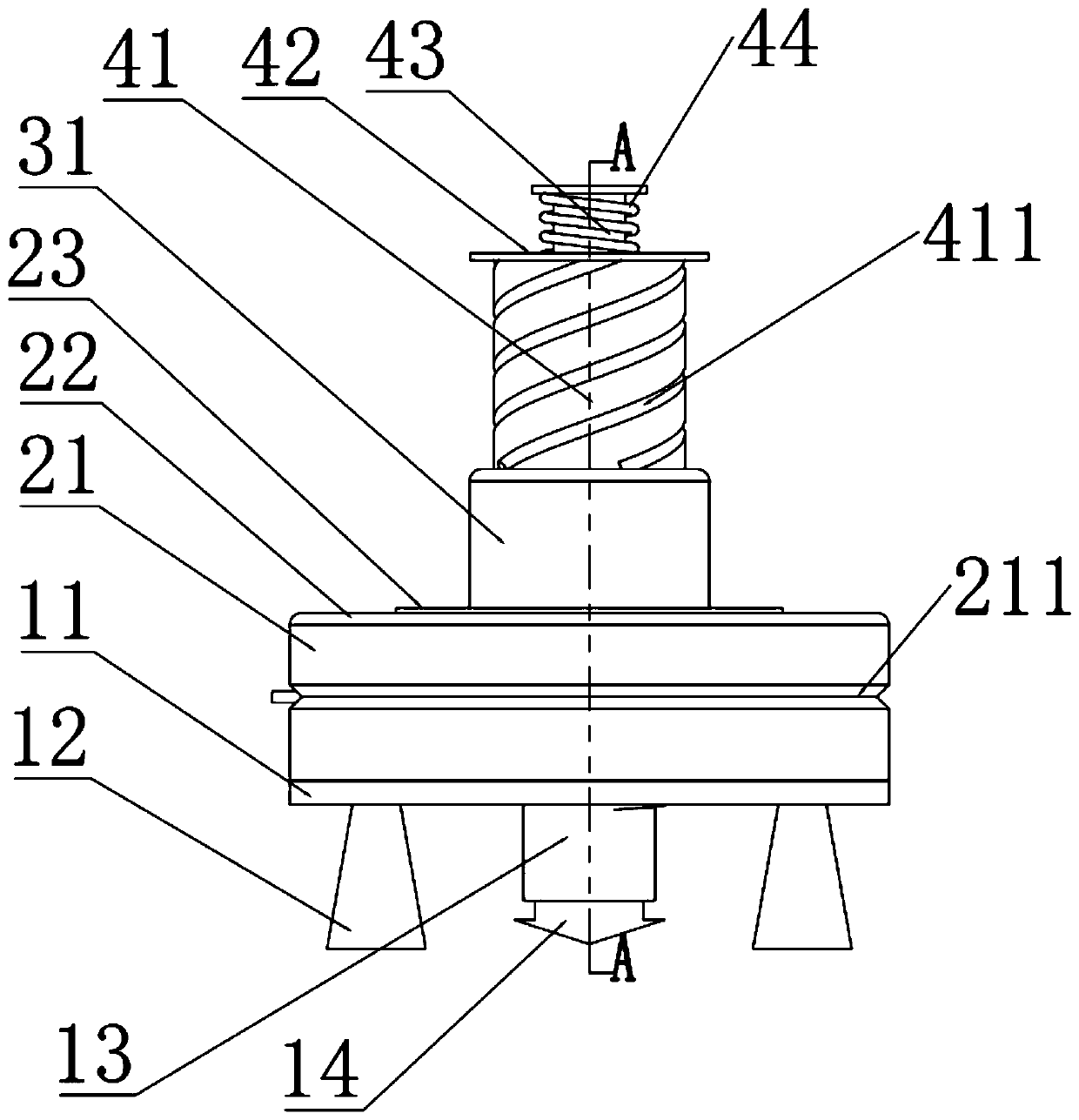

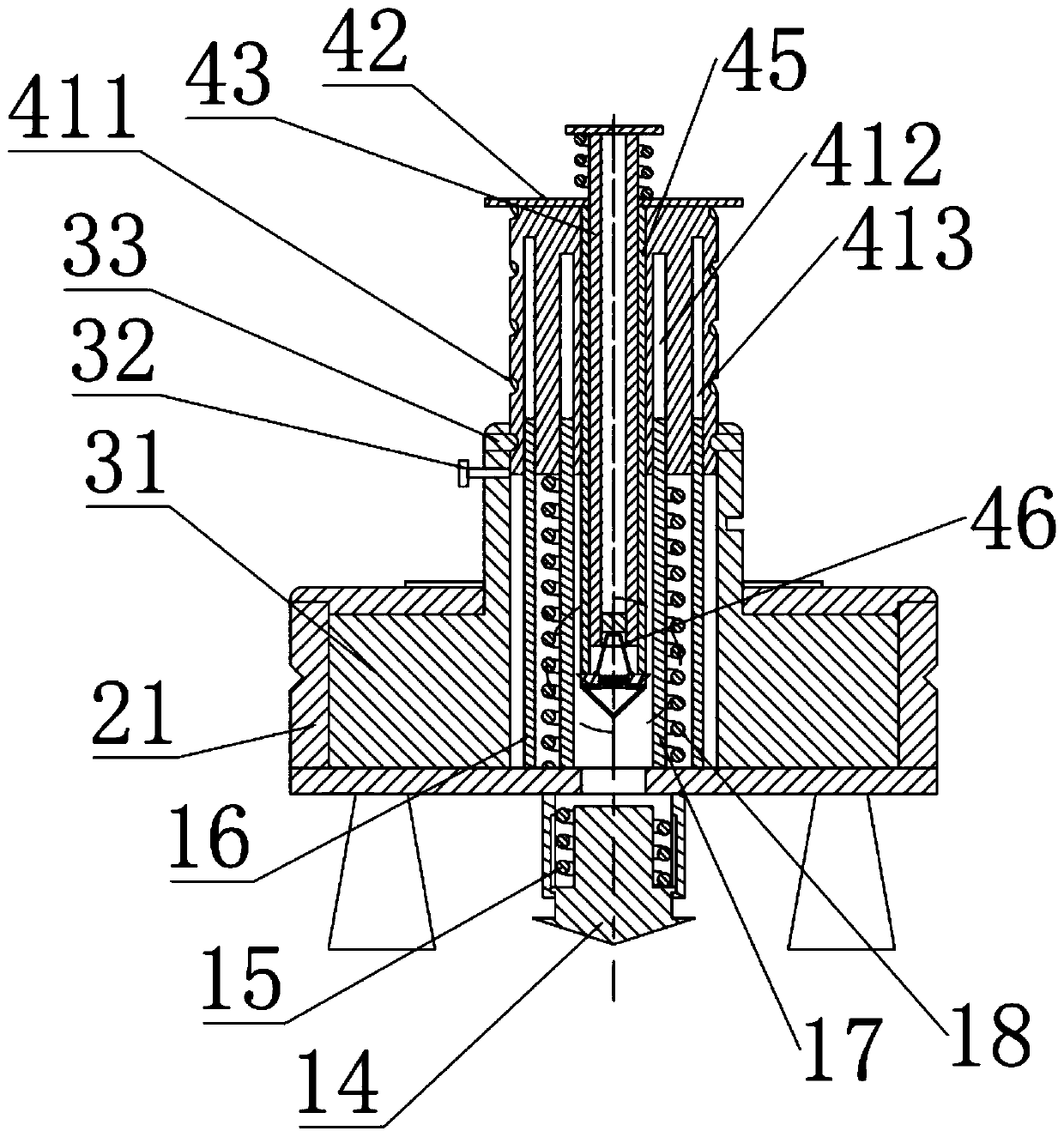

[0027] Such as Figure 1-9 As shown, the present invention provides a push-type multi-category control mechanism with a centered curve track, including a centering disc frame 1, a shaft sleeve cover 2, an inner shaft tube 3, a locking coil 4, a radial rotating rod 5, and a planet Shaft tube 6, winding reel disc 7, planetary rotating rod 8 and winding wheel set 9, the inner shaft tube 3 is installed in the center of the centering disk frame 1 through the rotation of the shaft tube outer cover, the belt lock The spiral tube 4 is slidably inserted on the centering frame 1 and fits with the center hole of the inner shaft tube 3. The surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com