Printing ink nozzle connecting piece

A technology for connectors and nozzles, which is applied in the field of printing and drawing, can solve the problems of non-universal nozzle connectors, complicated production process, troublesome assembly, etc., and achieve the effects of material saving, reasonable structure distribution and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

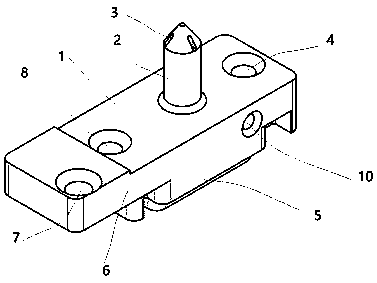

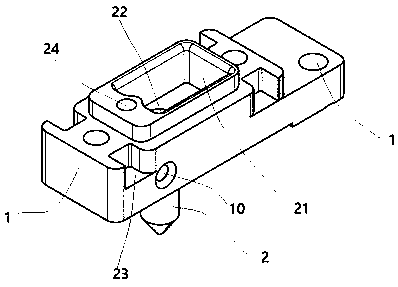

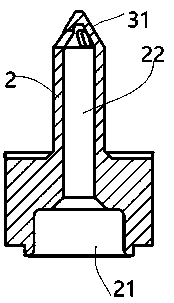

[0039] like figure 2 , 3 , 4, and 5, it is an ink nozzle connector, including an integrally formed base 1, an ink guide column 2 arranged on the base 1, an ink guide column arranged inside the ink guide column 2 and penetrating the base 1 The channel 22, the buffer tank 21 arranged under the base 1, the breathing channel arranged on the base, and the first fixing hole 4 and the second fixing hole 8 passing through the base 1; the base 1 consists of upper and lower halves 5 components, the upper and lower half 5 are cuboids, and the width is consistent, the length of the lower half 5 is less than the upper half 6, and the sides where the width of the upper and lower half 6, 5 are located have one side aligned.

[0040] like figure 1 As shown, in the Epson TX800 nozzle structure, a nozzle breathing hole 11 is arranged next to the two rows of ink inlet holes. The nozzle breathing hole 11 is used for the inflation and deflation of the built-in air bag of the nozzle. One air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com