Automatic control goods loading system

A technology for articles and vehicles, which is applied in the field of automatic control loading systems for articles, can solve the problems of low handling efficiency, adverse effects on the stability of cargo transfer, and high labor intensity for workers to handle, and achieve the effect of convenient telescopic movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

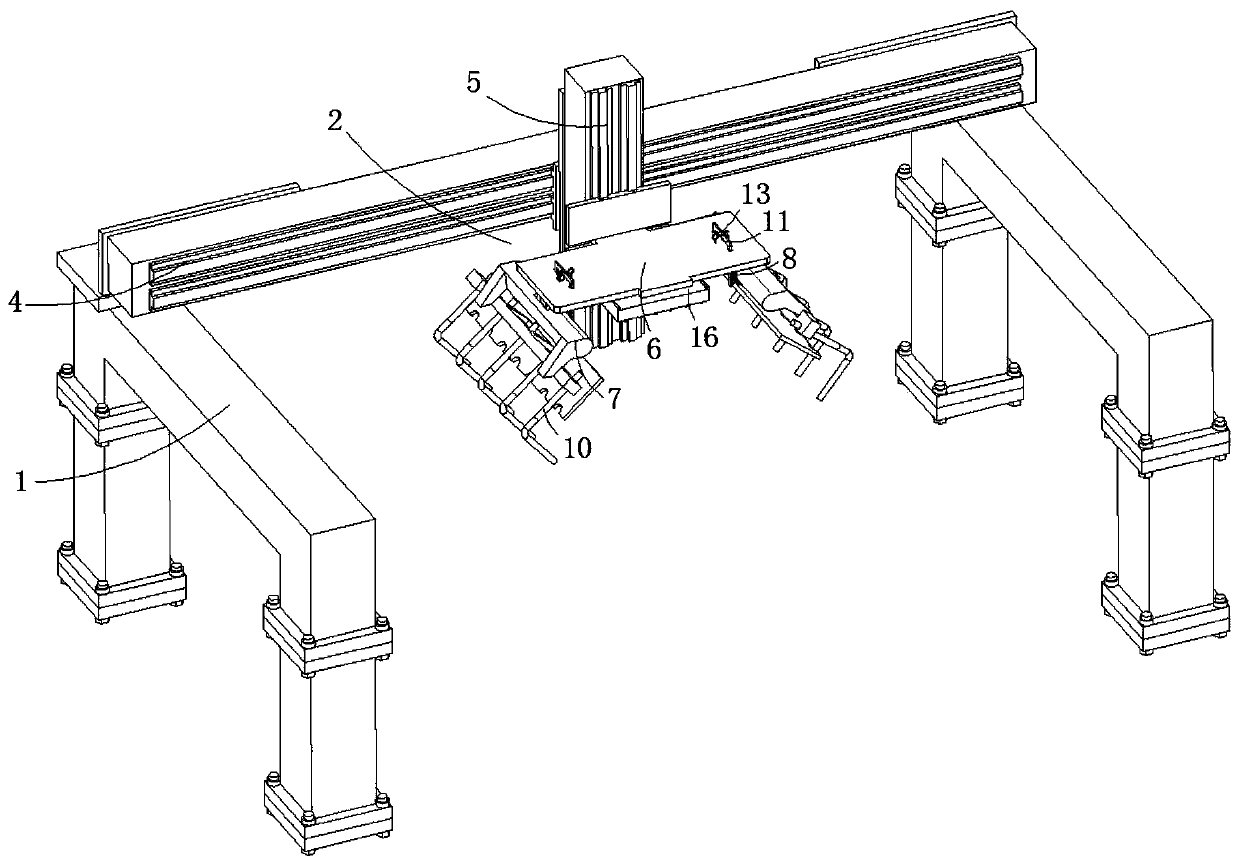

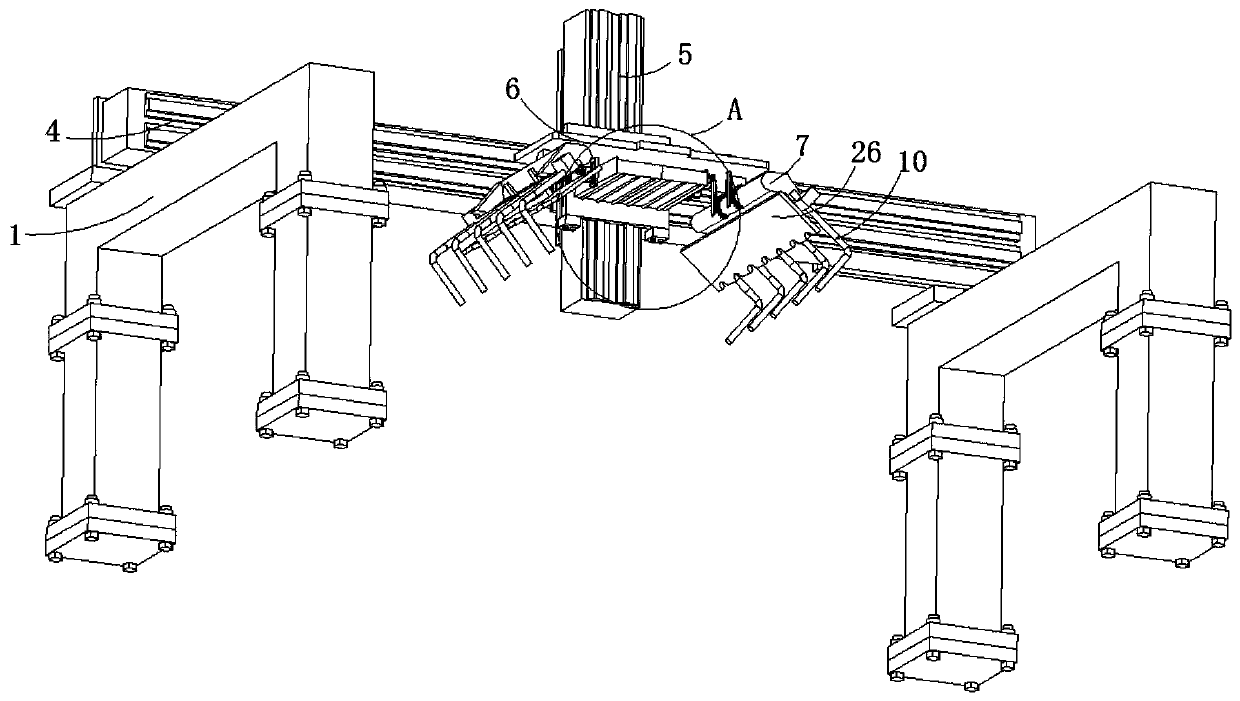

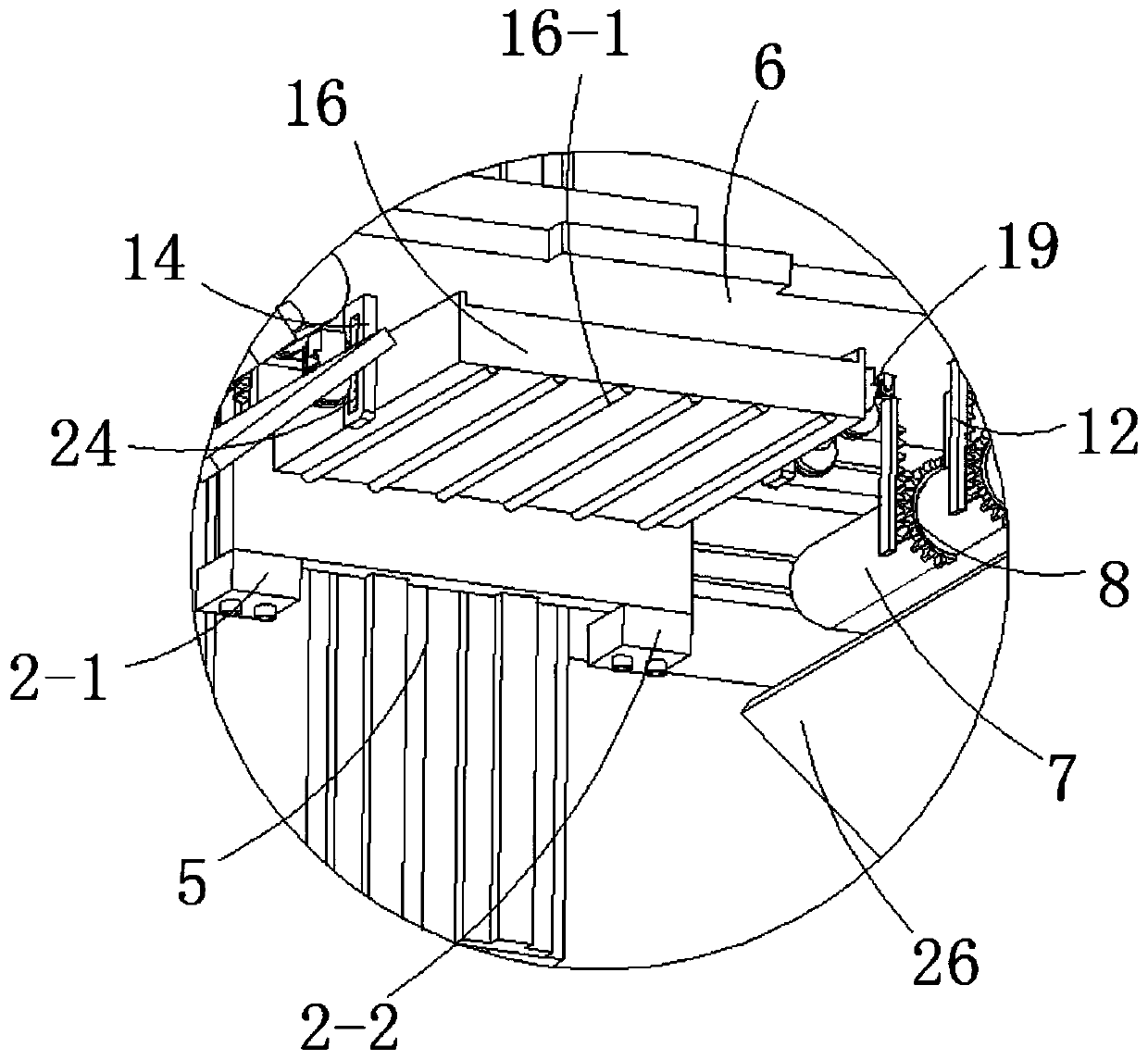

[0042] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6, Figure 8 , Figure 9 , Figure 11 , an article automatic control loading system, comprising a frame 1, a pick-up module 2, and a vehicle transfer module 3, the pick-up module 2 is fixed on the frame 1, the pick-up module 2, and the vehicle transfer module 3 are electrically connected in turn, and the pick-up module 2 includes the cargo identification unit 2-1, the three-dimensional scanning unit 2-2, and the grasping unit 2-3, and the cargo identification unit 2-1, the three-dimensional scanning unit 2-2, and the grasping unit 2-3 are electrically connected in sequence; The unit 2-3 comprises a horizontal linear motor 4, the mounting plate of the horizontal linear motor 4 is provided with a vertical linear motor 5, the mounting plate of the vertical linear motor 5 is fixedly provided with a mounting horizontal plate 6, and the bottom of the mounting horizontal plate 6 is rotatably provi...

Embodiment 2

[0046] refer to Figure 1-11 , an article automatic control loading system, comprising a frame 1, a pick-up module 2, and a vehicle transfer module 3, the pick-up module 2 is fixed on the frame 1, the pick-up module 2, and the vehicle transfer module 3 are electrically connected in turn, and the pick-up module 2 includes the cargo identification unit 2-1, the three-dimensional scanning unit 2-2, and the grasping unit 2-3, and the cargo identification unit 2-1, the three-dimensional scanning unit 2-2, and the grasping unit 2-3 are electrically connected in sequence; Unit 2-3 includes a horizontal linear motor 4, and a vertical linear motor 5 is arranged on the mounting plate of the horizontal linear motor 4;

[0047] The mounting plate of the vertical linear motor 5 is fixedly provided with a mounting horizontal plate 6. In actual use, the cargo identification unit 2-1 and the three-dimensional scanning unit 2-2 can be arranged on the mounting plate of the vertical linear motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com