Bead embroidery machine with bead blocking detection function and detection method

A bead embroidery machine and functional technology, which is applied in the field of embroidery machines, can solve problems such as bead hole blockage, lack of beads in embroidery, and affect the quality of embroidery, and achieve the effect of avoiding downtime and large areas of bead shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

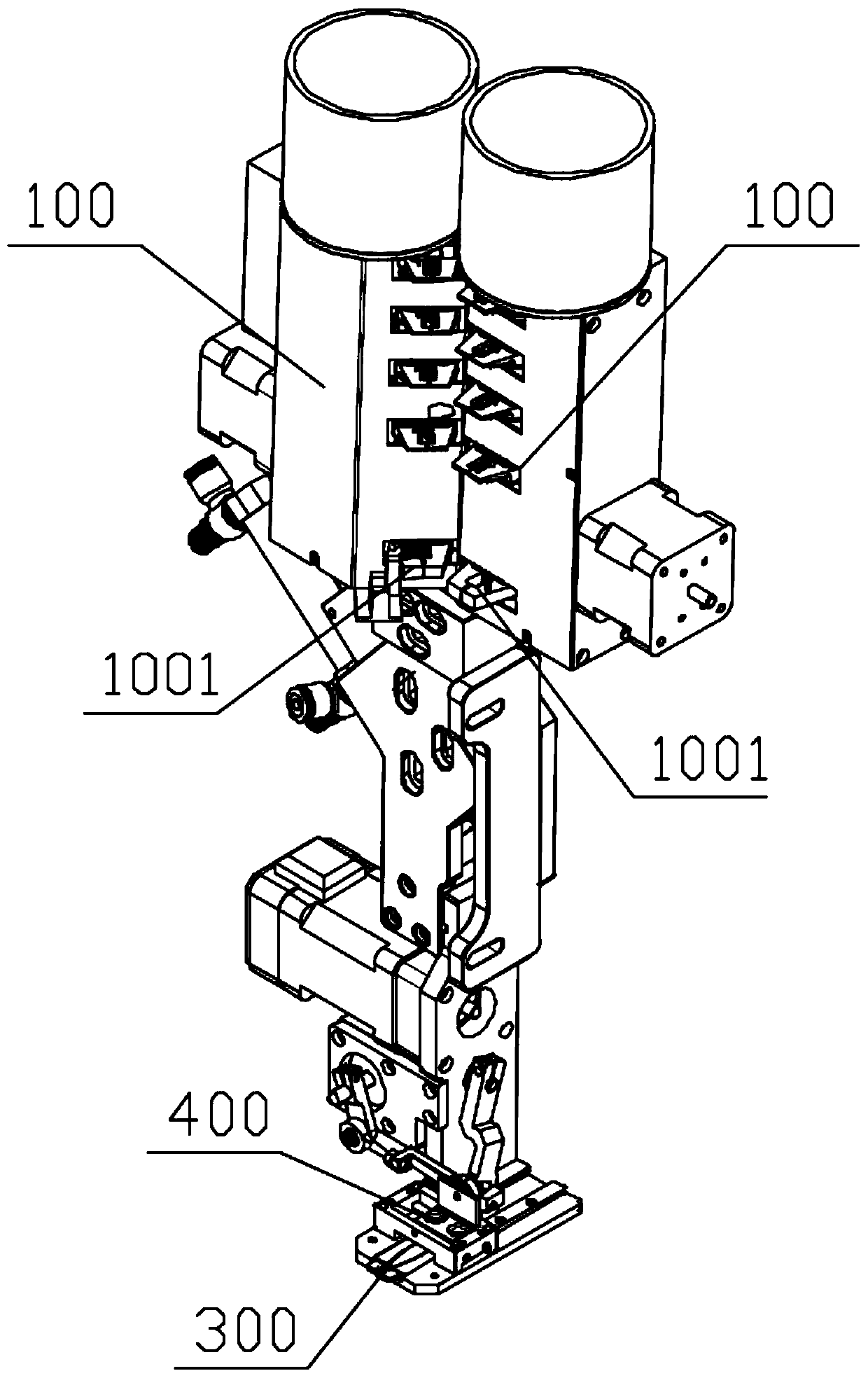

[0037] reference Figure 1 to Figure 7 As shown, a bead embroidery machine with a blocking detection function is installed on the head of the embroidery machine as a whole. It is provided with an embroidery bead control board that communicates with the main board of the embroidery machine. The bead embroidery machine is controlled through the embroidery control board. , To realize the synergy of sending beads and embroidery needles, embroidering the beads on the fabric.

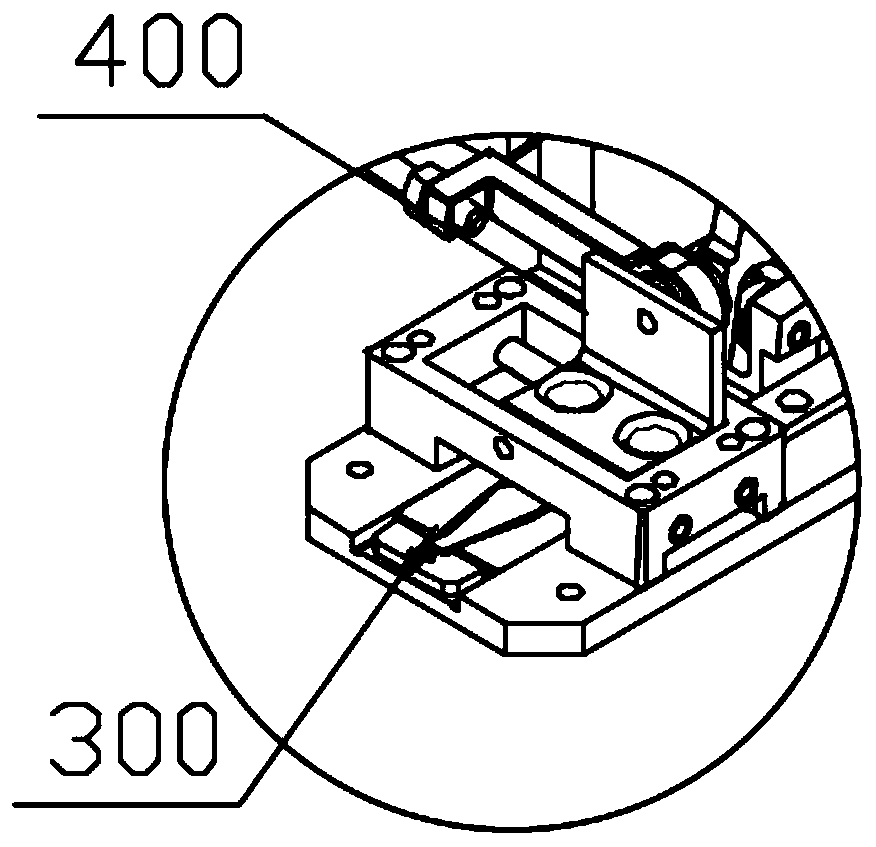

[0038] The bead embroidery machine includes a frame and a bead lowering device 100 and a bead feeding device 300 installed on the frame.

[0039] Among them, reference Figure 5 to Figure 7 As shown, the bead lowering device 100 includes a frame 9, a memory 1, and a spindle 4. The memory 1 is arranged on the frame 9, the spindle 4 is rotatably arranged on the frame 9, and the upper and lower ends of the spindle 4 are located inside and outside the memory 1 respectively. . The storage is generally cylindrical and ...

Embodiment 2

[0058] A method for detecting bead blocking of a bead embroidery machine, wherein the bead embroidery machine is the above-mentioned bead embroidery machine with the function of bead blocking detection, which is controlled by the embroidered bead control board:

[0059] When the beads are clamped by the bead induction clamp, the bead motor stops rotating;

[0060] The bead feeding device continues to feed the beads. When the bead feeding device continuously sends out N beads, the bead motor reverses X degrees and then returns to the original position. The beads on the lower bead wire are detected by the bead sensor clamp. If the beads are not clamped, start the beading motor and continue to load the beads; if the bead is clamped, wait for the next bead feeding device to continuously send out N beads and then test; if the beads are clamped three times in a row, control the bead motor to rotate once Detect, if the beads are still clamped, send a stop signal to the embroidery machine ...

Embodiment 3

[0065] The above-mentioned bead lowering device 100 is equipped with two solutions, which are called two-color bead tube embroidery device, which is controlled by the embroidery bead control board. The control method includes the most basic control of bead feeding and color change:

[0066] Sending beads: When the main board of the embroidery machine sends out a bead feeding signal, the embroidery bead control board controls the bead feeding device to send A color beads. The bead clamp waiting at the bottom of the bottom plate clamps the beads and sends them to the embroidery needle. When the embroidery needle penetrates the bead hole When inside, control the reverse rotation of the bead feeding motor to pull the bead clamp to the bottom of the lower bead hole. After receiving a bead, it rotates forward. The bead clamp clamps the bead and sends the bead to the waiting area of the bottom plate mouth, waiting for the next Bead sending signal;

[0067] Color change: When the main bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com