Dynamic inversion method for tight reservoir inter-well fracture aperture

A technology for fracture opening and tight reservoirs, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc. It can solve the problem of weak fracture identification, weak fracture identification ability between injection and production wells, and microseismic identification of reservoirs. Fracture and geomechanics predict reservoir fracture technology is easily affected by test accuracy and other problems, so as to improve the ability of fracture identification and prediction and reduce the cost of inversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

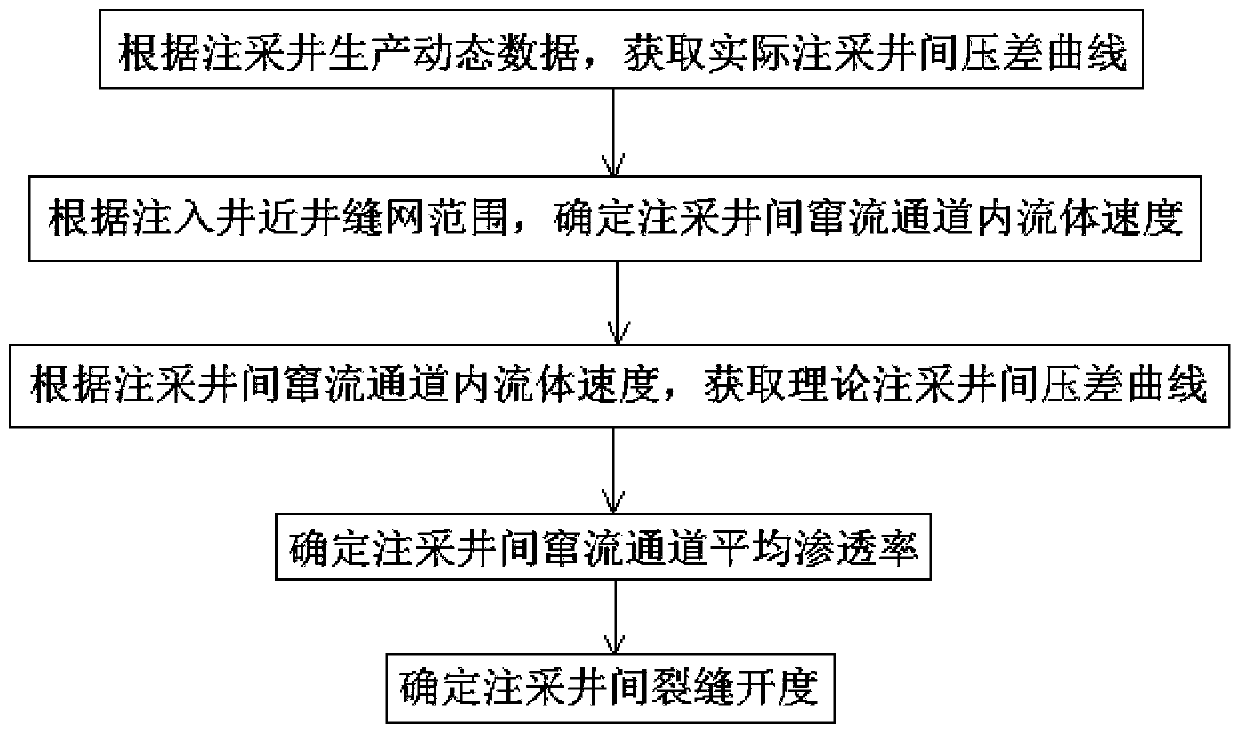

[0073] The dynamic inversion method for fracture opening between wells in tight reservoirs provided in Example 1, such as figure 1 As shown, the method includes:

[0074] (1) Collect production dynamic data of injection and production wells, and obtain actual pressure difference curve between injection and production wells;

[0075] (2) Determine the fluid velocity in the channeling channel between the injection and production wells according to the range of the fracture network near the injection well;

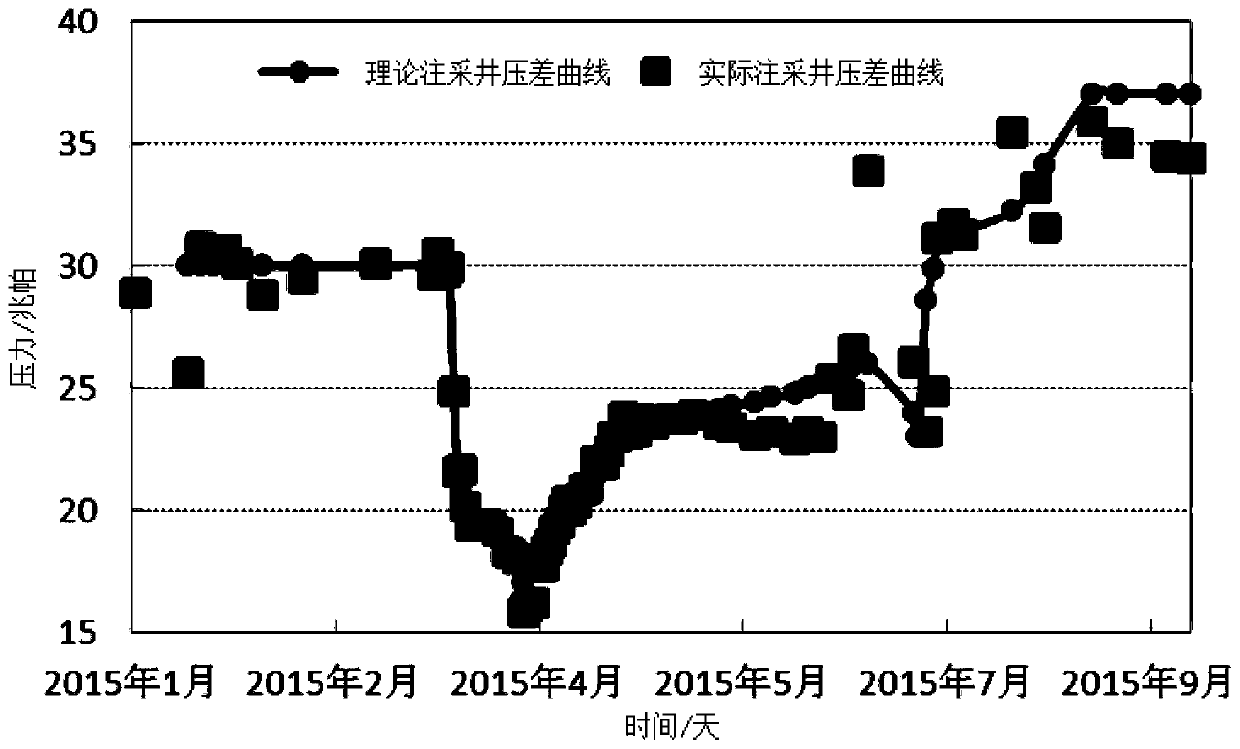

[0076] (3) Using the theoretical pressure difference formula between injection and production wells to obtain the theoretical pressure difference curve between injection and production wells;

[0077] (4) Fitting the theoretical pressure difference curve between injection and production wells and the actual pressure difference curve between injection and production wells to determine the average permeability of channeling channels between injection and production wells;

[...

Embodiment 2

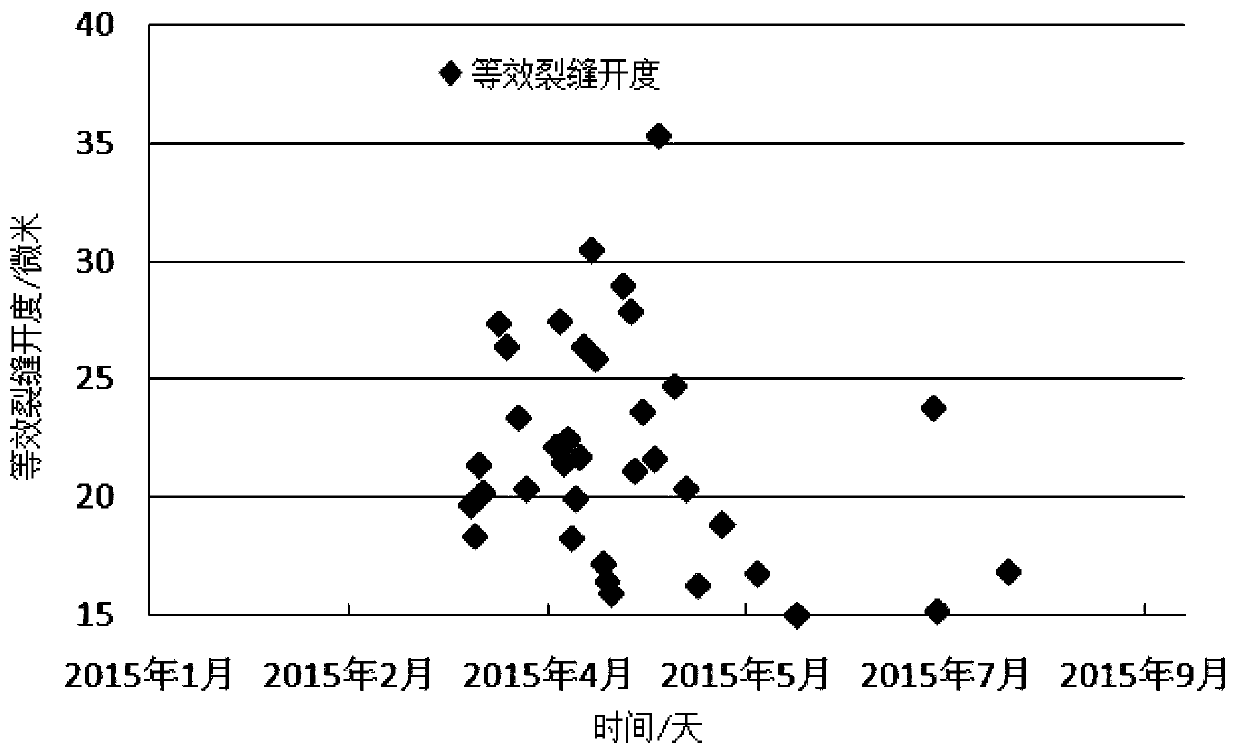

[0106] In order to have a more intuitive understanding of the application effect of the dynamic inversion method for interwell fracture opening in tight reservoirs provided in Example 1, the second embodiment uses the dynamic inversion of interwell fracture opening in a tight reservoir using the method of the present invention. The process is taken as an example to illustrate the specific implementation of the present invention. The average permeability and equivalent fracture opening of the channel between injection and production wells obtained by using the dynamic inversion method of interwell fracture opening in tight reservoirs provided in Example 1 (as shown in Table 1), wherein the basic data used (As shown in table 2).

[0107] Table 1. Average permeability and equivalent fracture opening of channeling channels between injection and production wells

[0108]

[0109]

[0110]

[0111] Basic data used in Table 2

[0112] Well spacing / m 600 Oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com