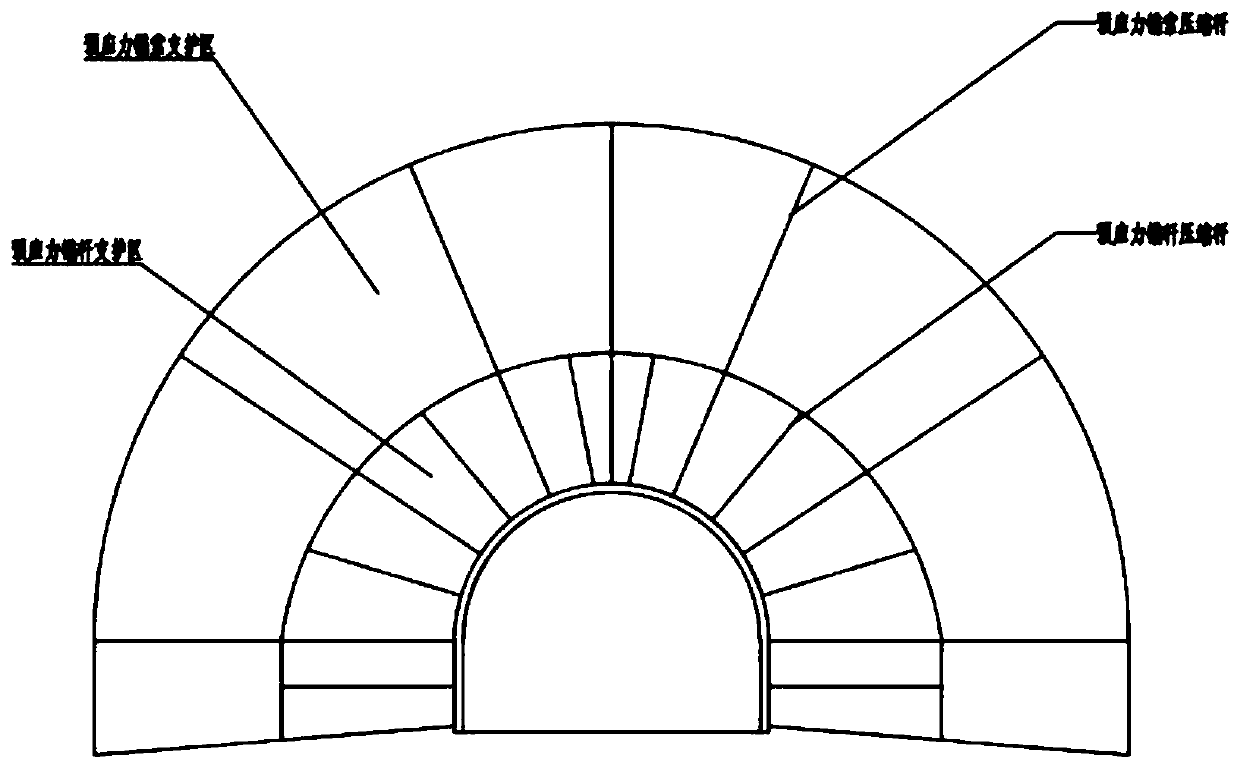

Arrangement method of compression arch of pre-stressed anchor rod in deep soft and weak rock large section roadway

A layout method and prestressing technology, which is applied in the installation of bolts, measuring devices, earthwork drilling and mining, etc., can solve the problems of not considering lithology changes, and the difficulty of forming effective compression arches, etc., so as to reduce drilling costs, The effect of reducing secondary support costs and safe and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

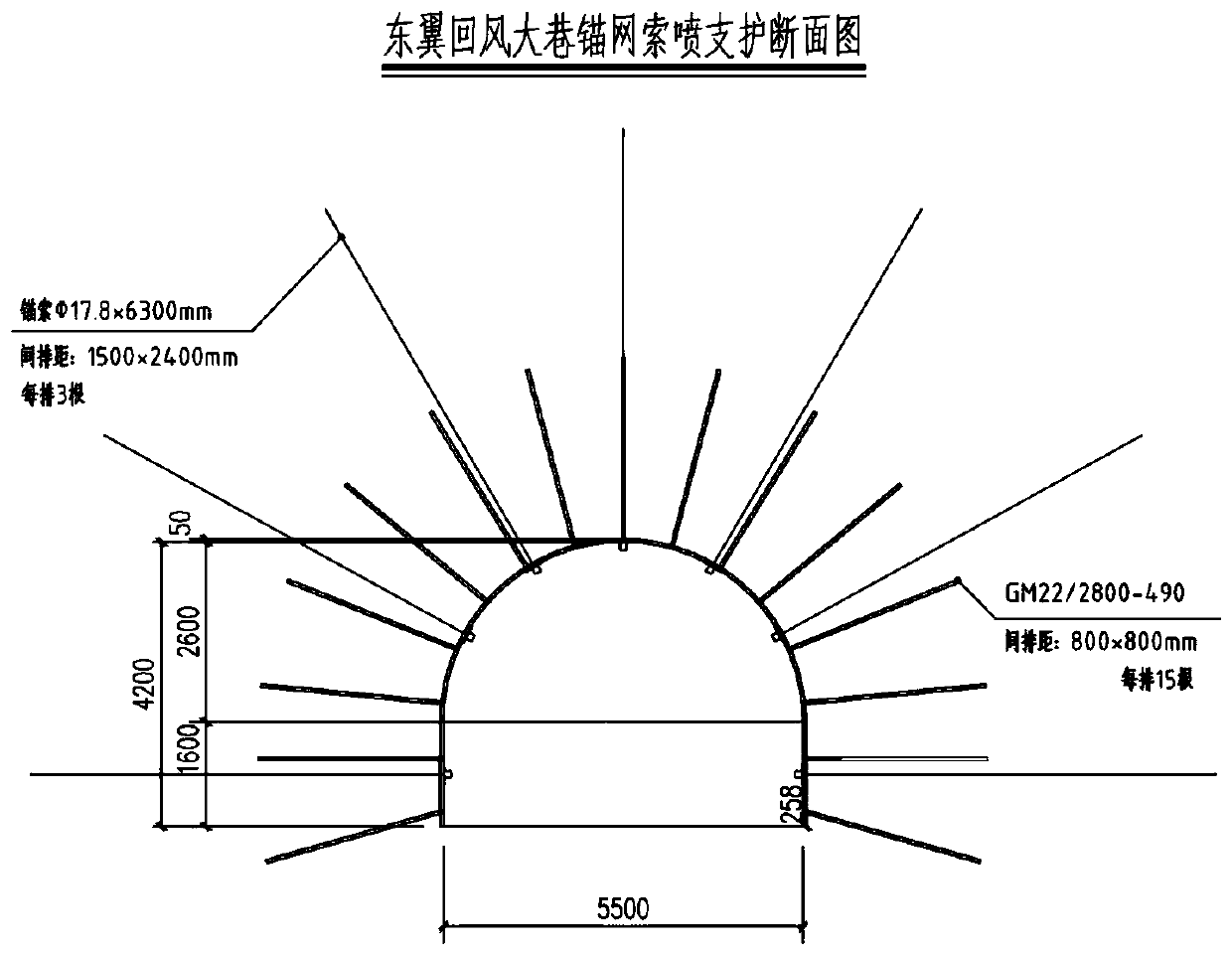

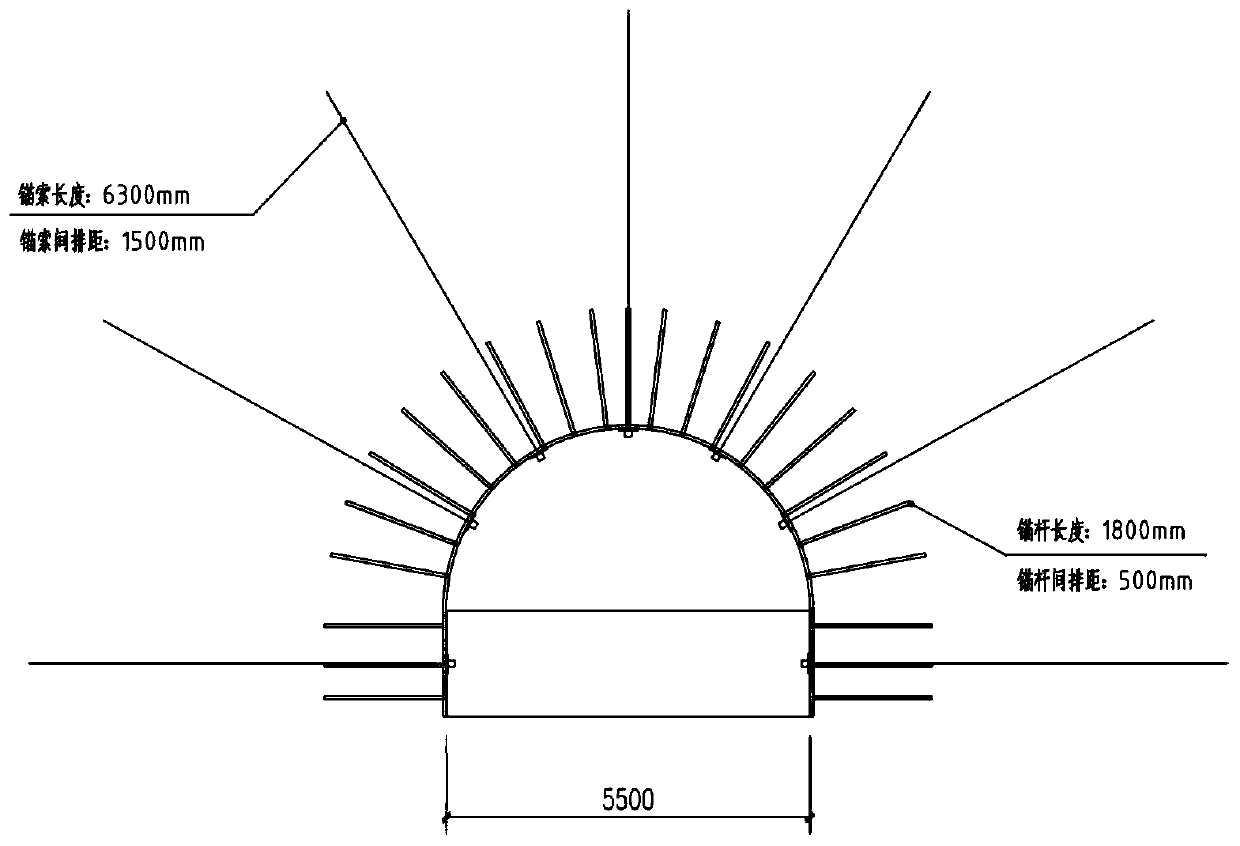

[0027] See attached Figure 1-7 Take the return air alley in the south wing of Yuanyi Mine in Huaibei, Anhui Province as an example:

[0028] (1) Original roadway support and support effect:

[0029] The air return road in the south wing of Yuanyi Mine in Huaibei, Anhui is mainly used for air return. The roadway is buried at a depth of about 750m and the excavation length is about 3400m. During the excavation process, it mainly passes through coal rock, weak ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com