A method for judging the adequacy of fermentation of waste in a waste incineration plant

A waste incineration and sufficient technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of incinerator damage, unstable calorific value of waste entering the furnace, and increased risk of pollutant discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

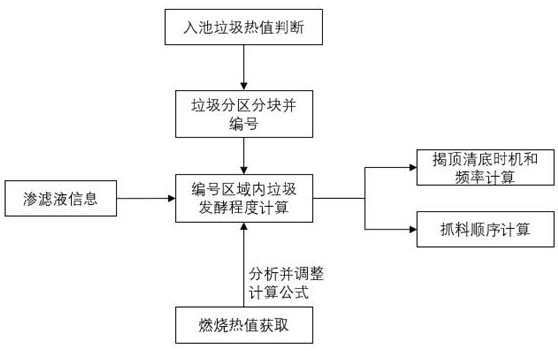

[0025] as Figure 1As shown, a method for judging the sufficiency of waste fermentation in waste incineration plants includes the following steps: The first step: Obtain the calorific value of the waste entering the plant. The method of acquisition includes the following steps: Step 1: The calorific value is generally relatively stable, which can be obtained according to a professional measuring instrument, and can be measured once; Step 2: Through the season, the area where the incineration plant is located, the city, the outdoor temperature and other conditions, output the average value of the inlet garbage that meets the conditions, the system records the measurement results of each instrument, and enters the factors affecting the calorific value of the infill garbage into the database.

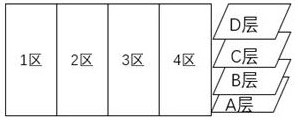

[0026] Step 2: Measure the length, width and height of the waste pool of the incineration plant to obtain the volume of the garbage pool, such as Figure 1 The garbage pool length direction is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com