Batched cutting and detecting integrated device for pastry production

A pastry and batch technology, which is applied in the field of batch cutting and detection integrated devices for pastry production, can solve the problems of manpower consumption and low efficiency, and achieve the effects of improving quality, high detection efficiency and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

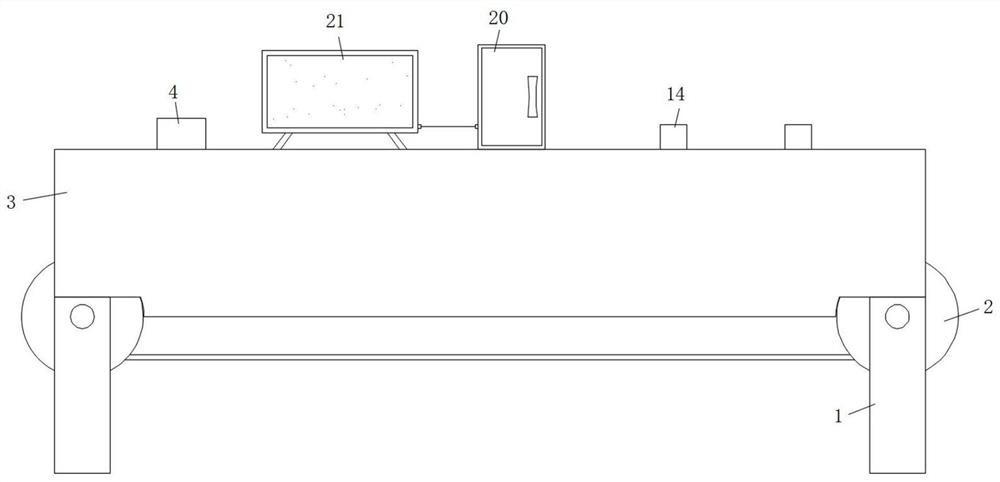

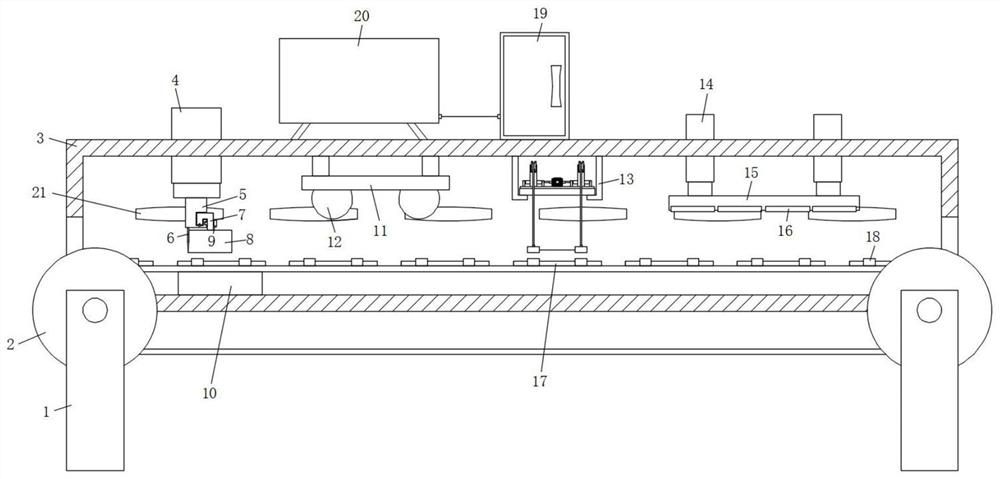

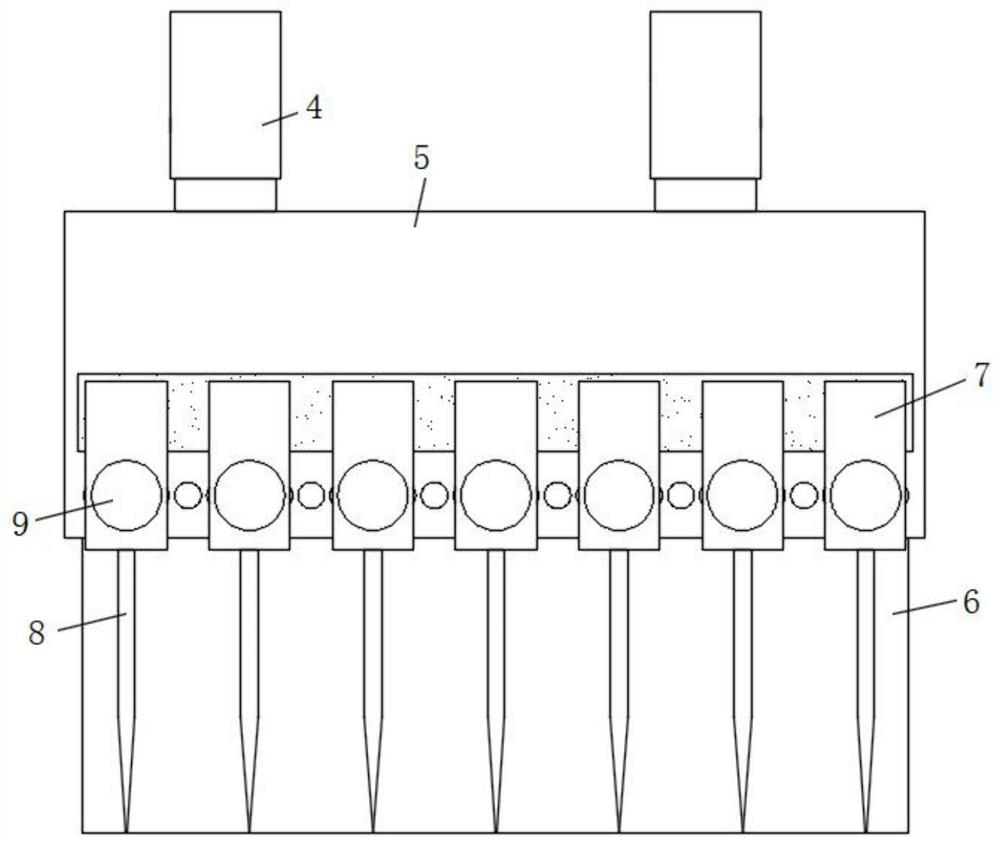

[0034] refer to Figure 1-6, an integrated device for batch cutting and detection for pastry production, comprising a mounting base 1, a conveyor belt 2 is installed on the upper end of the mounting base 1, a limit mold is fixed on the belt surface of the conveyor belt 2, and a plurality of limit molds are evenly distributed On the belt surface of the conveyor belt 2, a processing box 3 is also fixed on the top surface of the mounting seat 1, and a slitting mechanism is fixed on one side of the inner top surface of the processing box 3. The slitting mechanism includes an electric telescopic rod-4, an electric telescopic rod- The output end of 4 is fixedly connected with a mounting plate 5 by screws, a vertical cutting blade 6 is fixed on one side of the bottom surface of the mounting plate 5, and a mounting groove is provided in the middle part of the side of the mounting plate 5 away from the vertical cutting blade 6, and sliding in the mounting groove A mounting block 7 is c...

Embodiment 2

[0037] Such as figure 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the inner walls of the front and rear ends of the processing box 3 are fixed with ultraviolet sterilizing lamps 21, and a plurality of ultraviolet sterilizing lamps 21 are provided and evenly distributed in the processing box. 3. On the inner wall of the front and rear ends, the control ends of the electric telescopic rod 1 4, the biaxial motor 1310, the electric telescopic rod 2 14, the drying lamp 16 and the ultraviolet sterilizing lamp 21 are electrically connected to the output end of the electric control box 19, The output end of the electronic scale 1302 is electrically connected to the input end of the electric control box 19 , and the input end of the display panel 20 is electrically connected to the output end of the electric control box 19 .

[0038] In this embodiment, a plurality of ultraviolet sterilizing lamps 21 are evenly fixed on the inner walls of the front a...

Embodiment 3

[0040] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, four mounting bases 1 are provided and fixed on the working surface in a rectangular shape. Both sides of the top surface of the processing box 3 are provided with cylindrical holes, and the electric telescopic rod The first 4 and the second electric telescopic rod 14 are all fixedly connected on the inner wall of the cylindrical hole by screws.

[0041] In this embodiment, the stability of the cutting mechanism and the drying mechanism is ensured by fixing the first electric telescopic rod 4 and the second electric telescopic rod 14 on the inside of the top surface of the processing box 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com