Cutting device for artificial leather processing and using method thereof

A technology for cutting artificial leather, applied in the fields of transportation and packaging, textiles and papermaking, and cutting of textile materials. It can solve the problems of delaying the cutting efficiency of artificial leather, increasing the labor load of operators, and lack of cleaning mechanisms, etc., and achieves the improvement of cutting efficiency and structure. Compactness and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

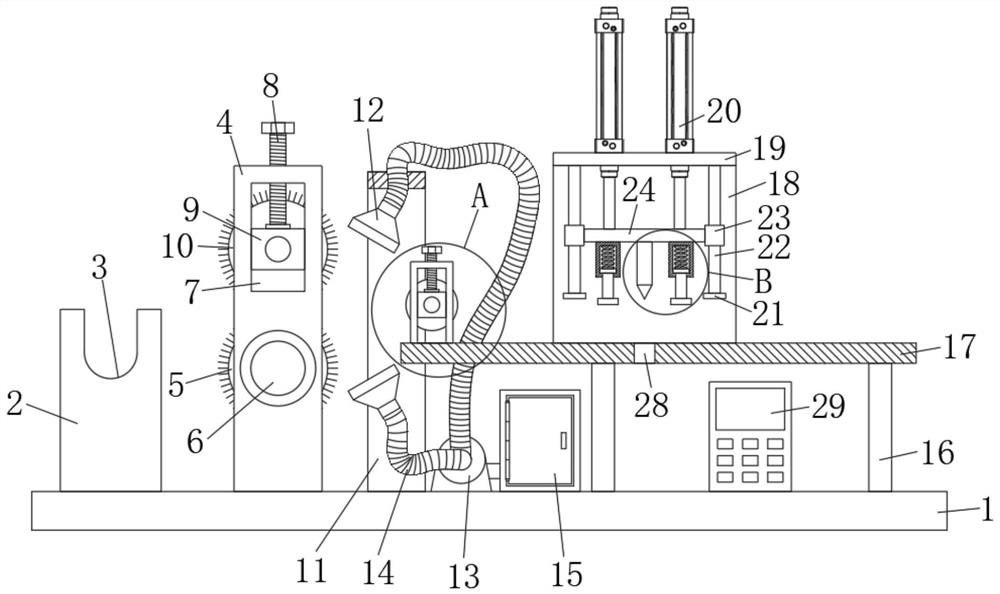

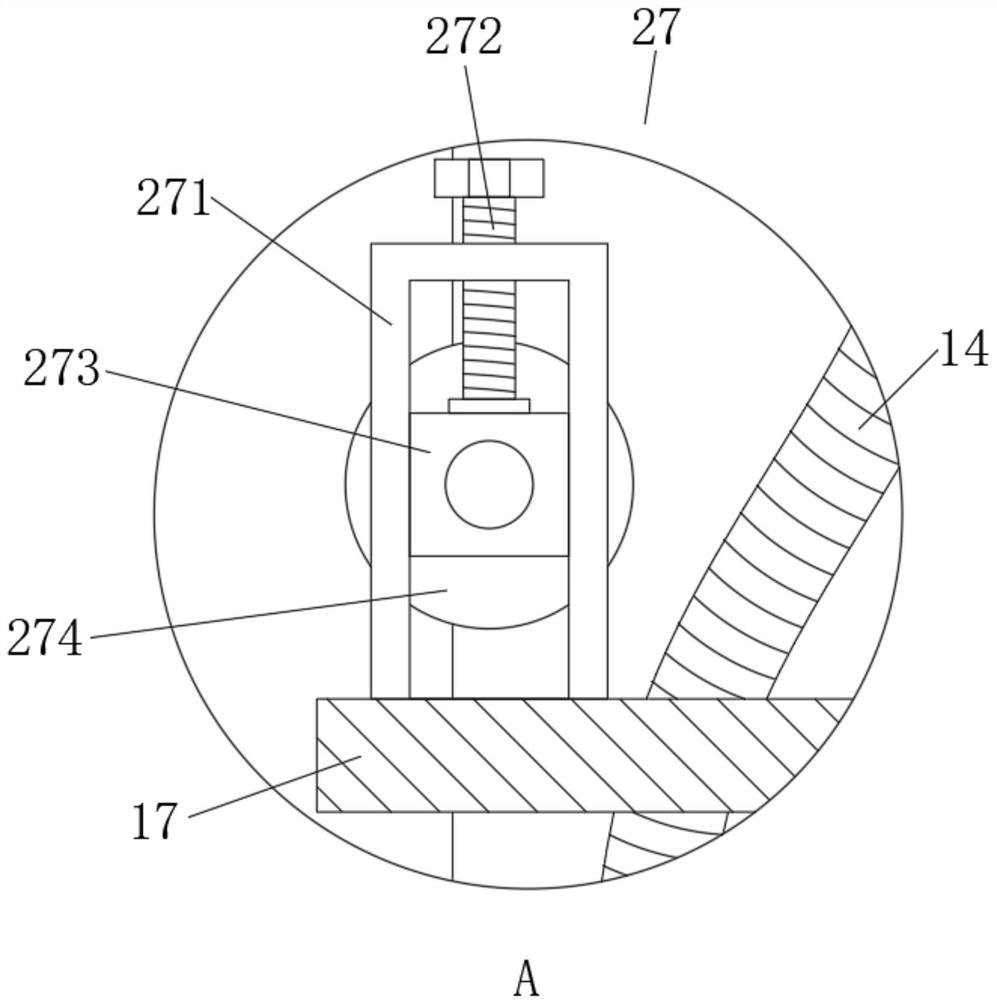

[0027]A cutting device for artificial leather processing, comprising a bottom plate 1, through which the whole device can be placed more stably; one end of the top of the bottom plate 1 is fixedly connected with two fixed plates 4, and the two fixed plates 4 The bottom is rotatably connected with the first conveying roller 5, and the outer side of the bottom of one of the fixed plates 4 is fixed with a servo motor 6, and the output shaft of the servo motor 6 passes through the corresponding fixed plate 4 and is connected to the first conveying roller 5. Fixedly connected, the servo motor 6 is convenient to better drive the first conveying roller 5 to rotate; the outside of the fixed plate 4 and above the first conveying roller 5 are all provided with a limit groove 7, and the top of the fixed plate 4 All are threadedly connected with a first adjusting screw rod 8, and the bottom of the first adjusting screw rod 8 extends to the inside of the corresponding limit groove 7 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com