Multi-point triggered ternary lithium power battery module thermal runaway simulation and prediction method

A technology of power battery and prediction method, applied in design optimization/simulation, special data processing application, computer-aided design, etc., can solve problems such as uneven heating position of battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

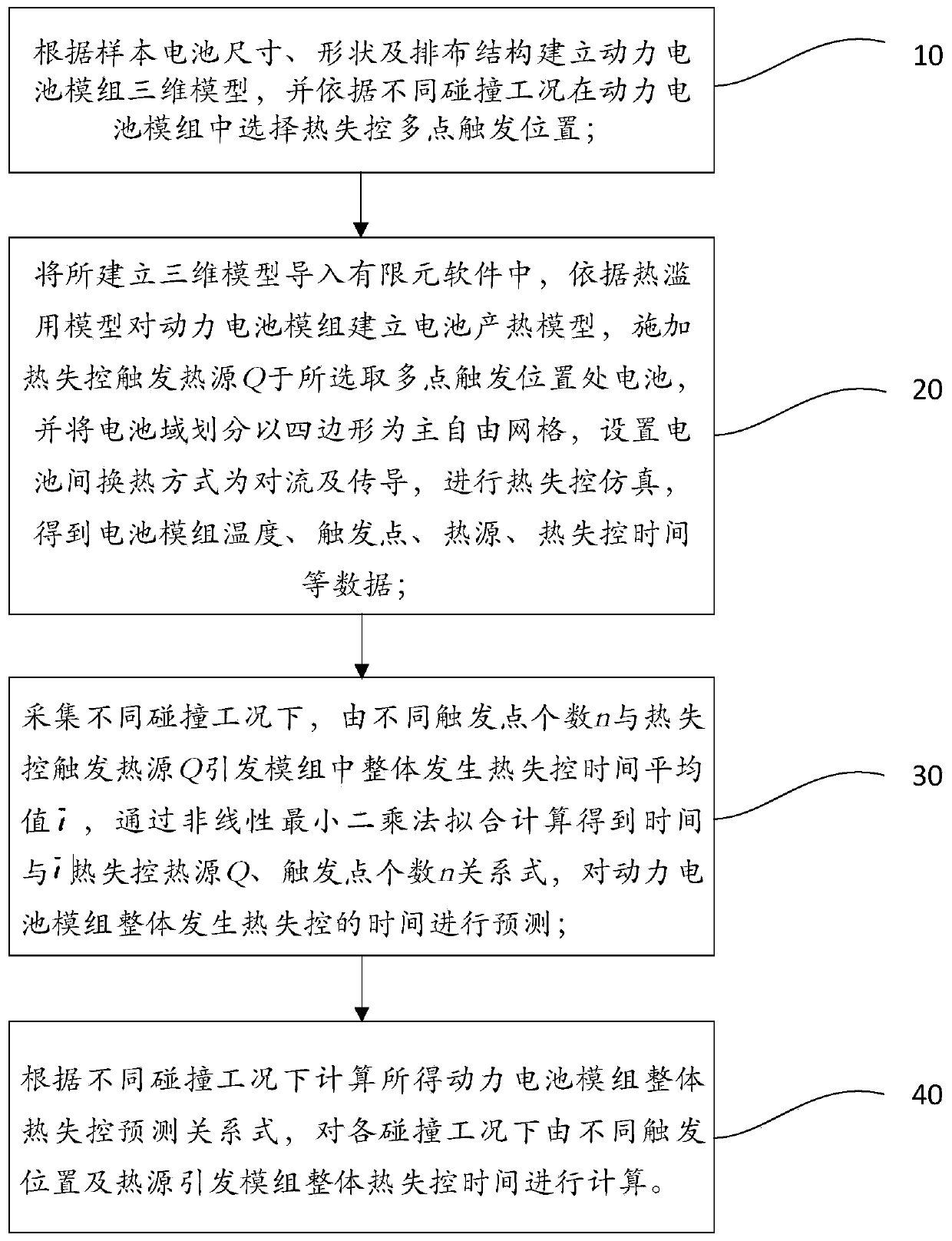

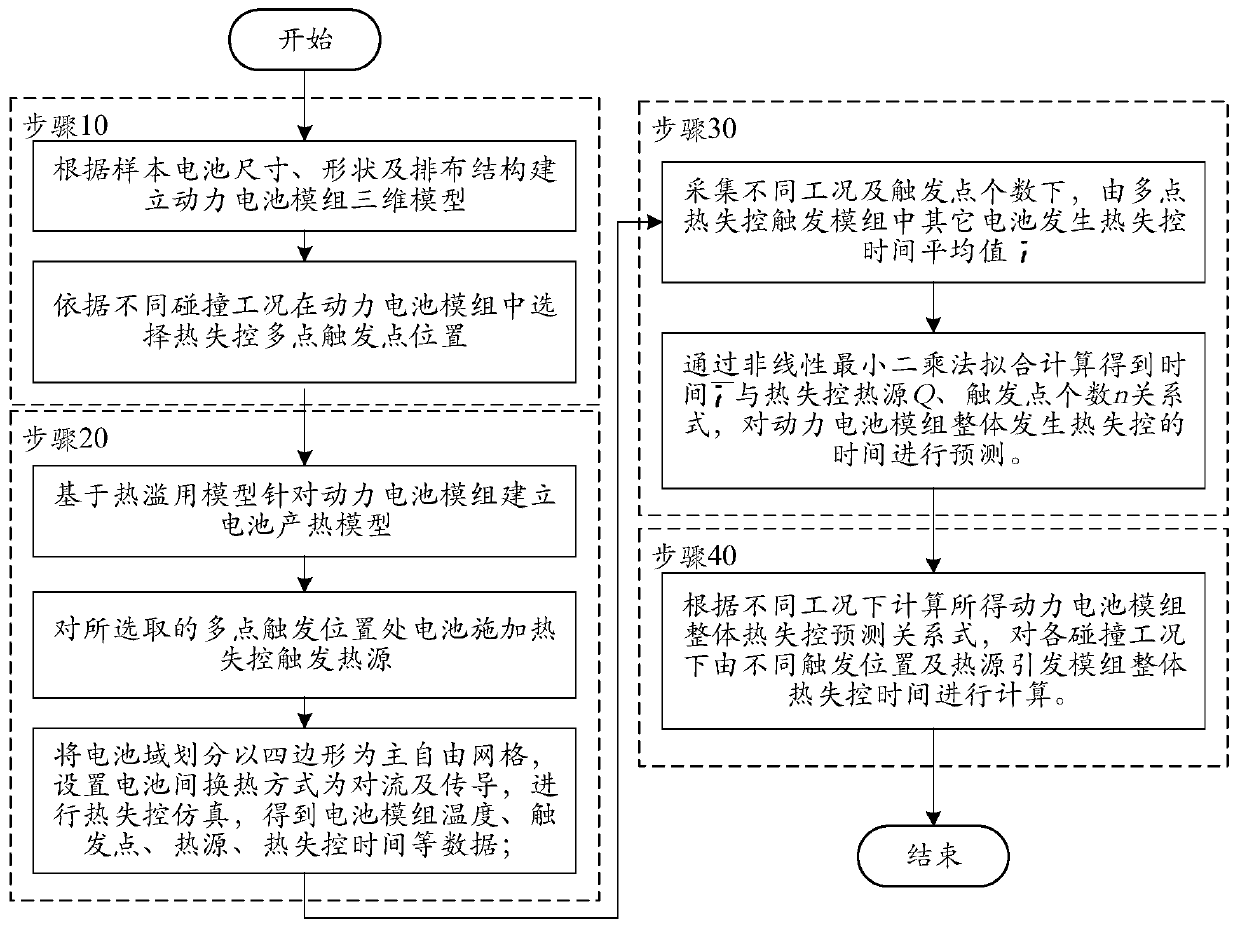

[0024] Such as figure 1 and figure 2 As shown, the workflow of the thermal runaway simulation method of the power battery module with multi-point triggering includes: building a three-dimensional model of the power battery module, selecting a multi-point trigger position, modeling with a quadrilateral free mesh, and applying a heat source to calculate the battery thermal field. Collect data and fit calculations to predict the overall thermal runaway time of the power battery module Relational. Specifically include the following steps:

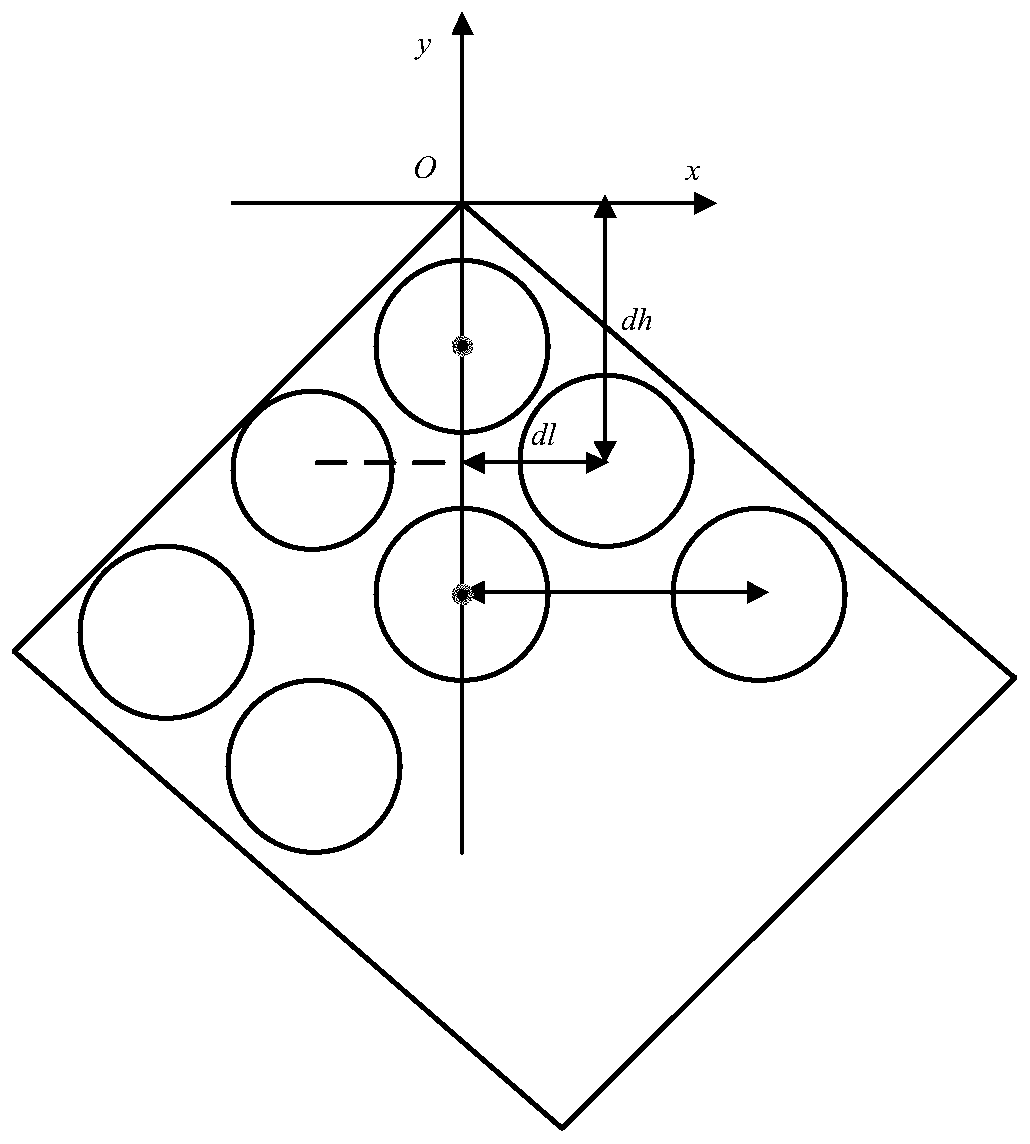

[0025] Step 10 Establish a 3D model of the power battery module based on the size, shape and arrangement of the sample batteries, and select thermal runaway in the power battery module according to different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com