A device for fast threading of cable elbow sleeves

An elbow tube and cable technology, which is applied to cable laying equipment and other directions, can solve the problems of time-consuming and laborious, wear of protective layer elbow cable sleeve, affecting the mechanical strength, airtightness and use time limit of the sleeve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

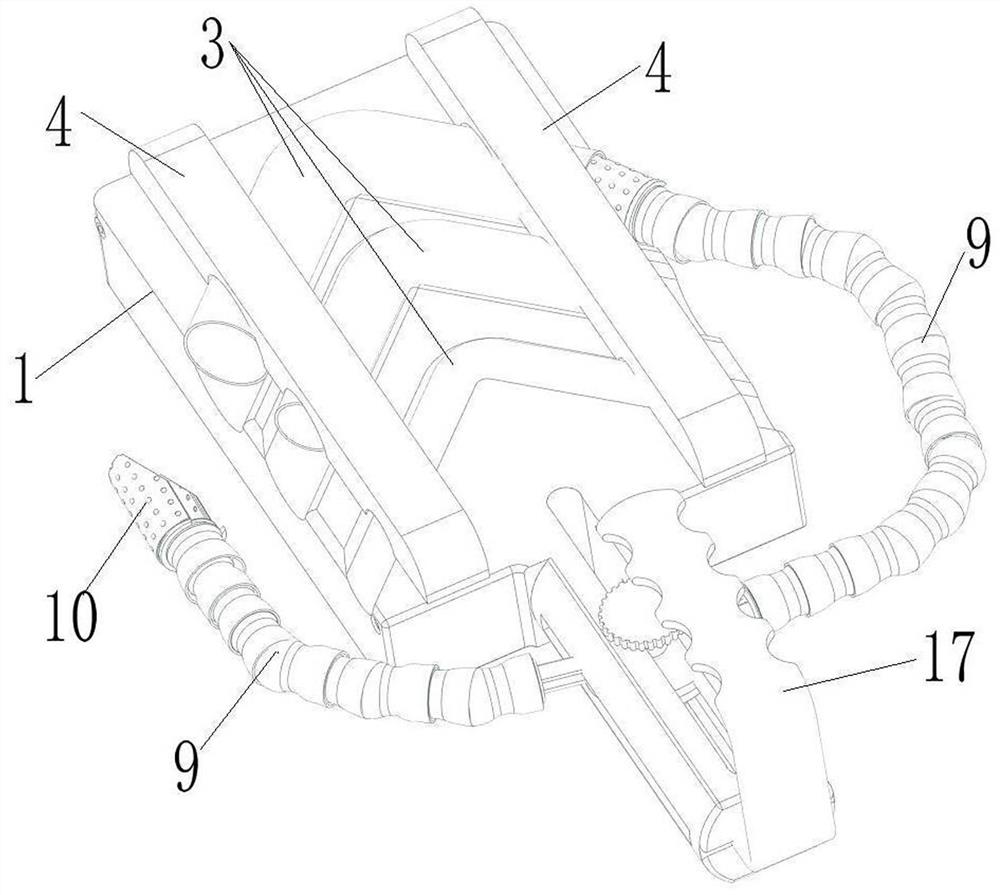

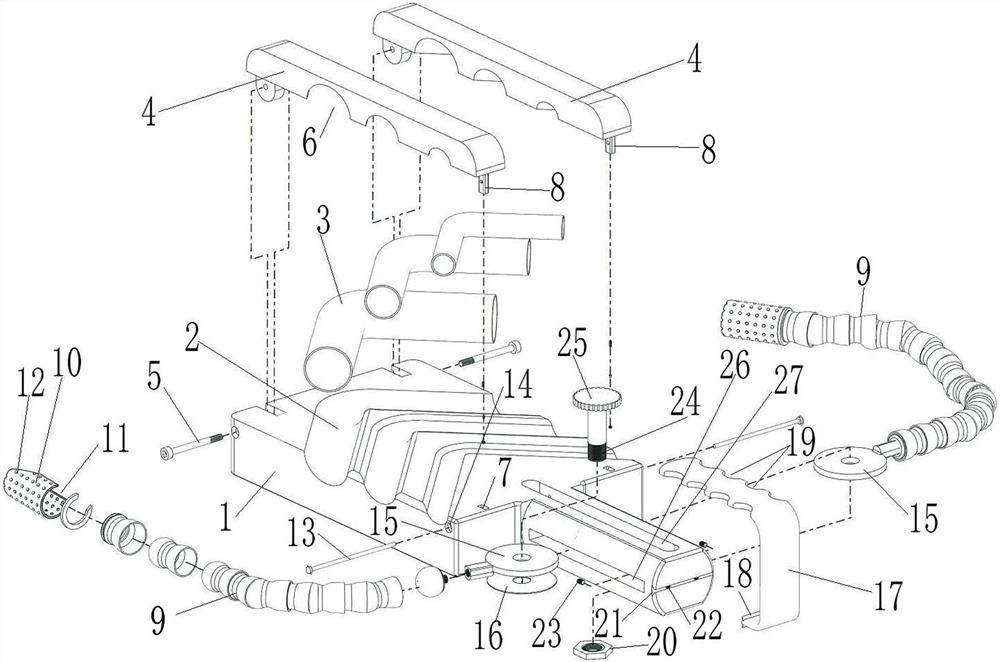

[0022] Attached below figure 1 , attached figure 2 , attached image 3 The present invention will be further described.

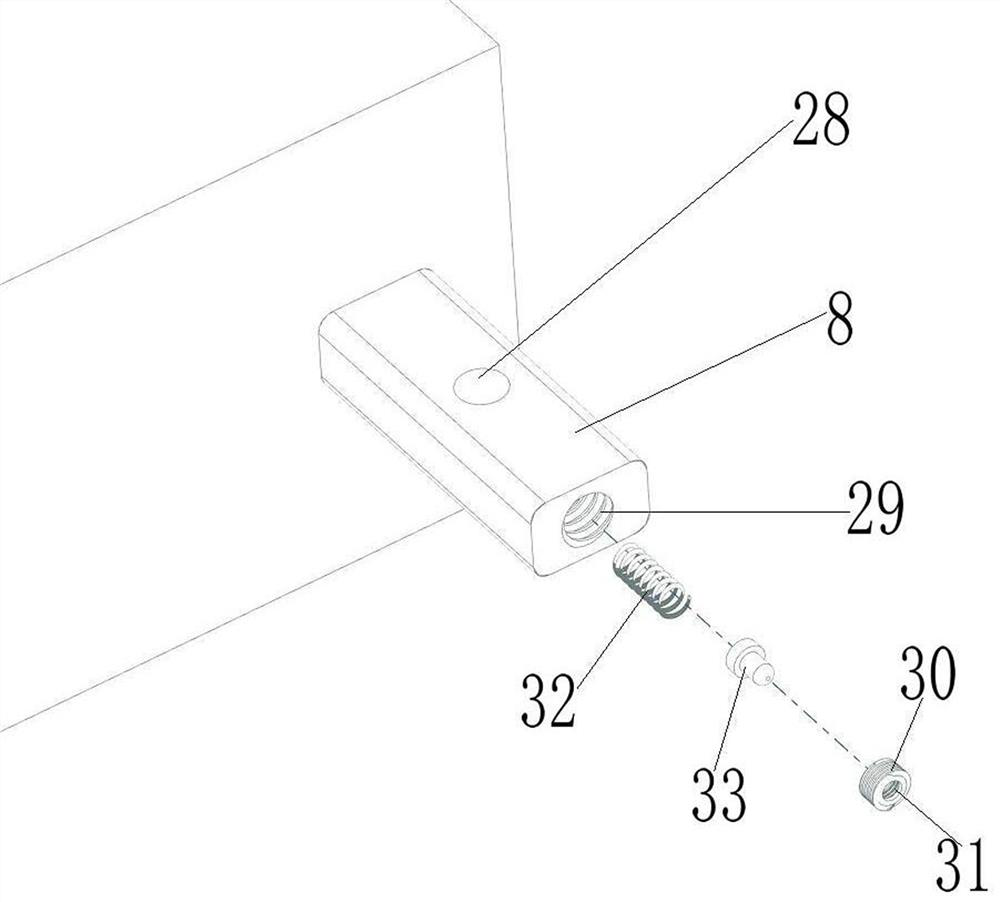

[0023] A device for fast threading of cable elbow sleeves, comprising: a base 1, which is provided with a number of slots I 2 with different inner diameters inside, and the lower end of the elbow cable sleeve 3 is placed in the corresponding slots I 2 ; the card arm 4, its rear end is installed on the base 1 through the rotating shaft 5 rotation, the lower end of the card arm 4 is provided with a number of card slots II 6 corresponding to the card slot I 2, when the card arm 4 rotates to the horizontal state, the card The arm 4 is locked and fixed relative to the base 1 by the locking device, and the card slot II 6 is fastened to the upper end of the corresponding elbow cable sleeve 3; two plastic universal flexible shafts 9 are respectively located on the left and right sides of the base 1 , the front end of the plastic universal flexible shaft 9 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com