A waste pipe cutting rust removal device

A pipe and waste technology, applied in the field of waste pipe cutting and derusting devices, can solve the problems of reducing processing efficiency, wasting human resources, manual cutting, etc., and achieve the effects of improving processing efficiency, enhancing practicability, and enhancing cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

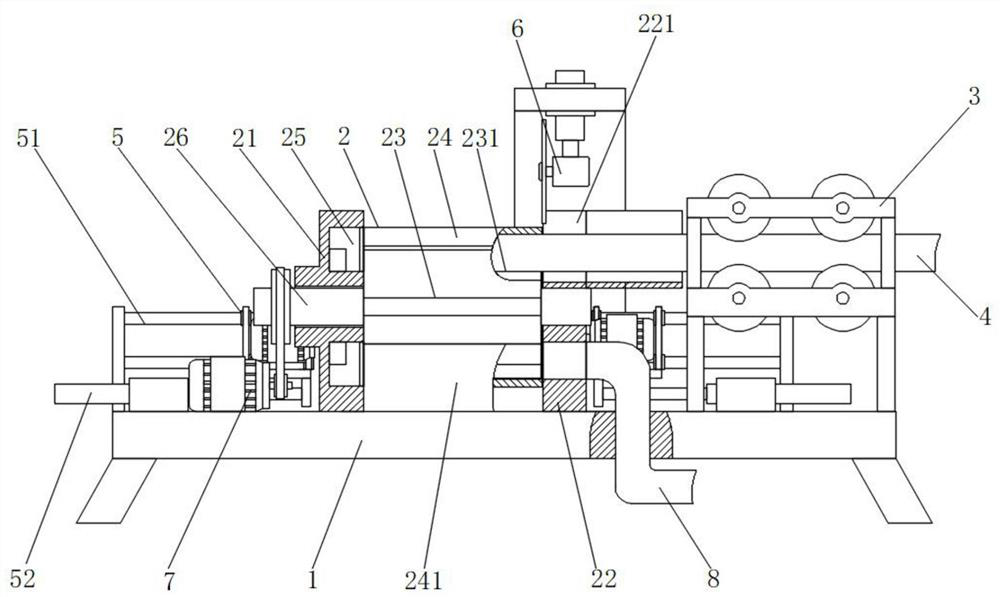

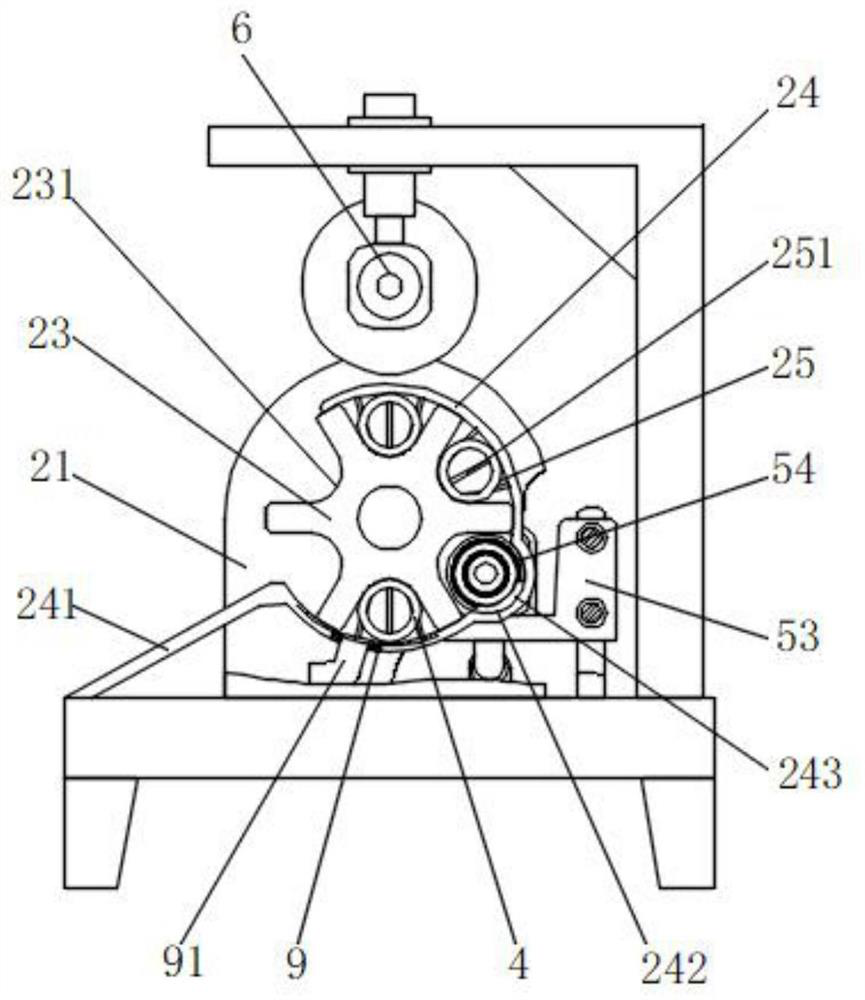

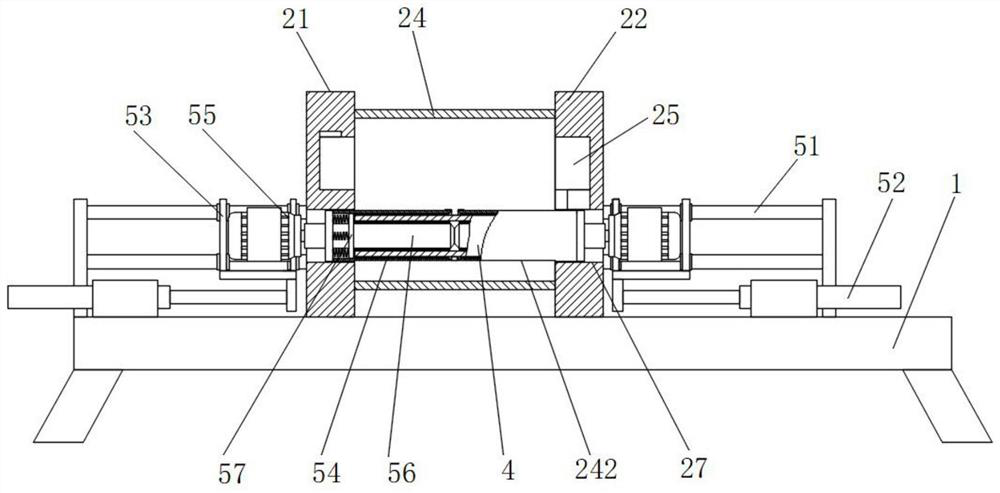

[0030] The present invention provides such Figure 1-8The shown device for cutting and derusting waste pipes includes a base 1, a clamping and conveying mechanism 2 is arranged on the top of the base 1, and a pipe conveying roller 3 is installed on one end of the top of the base 1, and the pipe conveying roller 3 A pipe 4 is arranged inside of the pipe 4, a grinding mechanism 5 is provided at the bottom of one side of the clamping and conveying mechanism 2, and a lift cutting machine 6 is arranged on the top of the clamping and conveying mechanism 2 near one end of the pipe conveying roller 3, and the lift and cut The machine 6 is fixedly installed on the top of the base 1, the clamping and conveying mechanism 2 includes a first end plate 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com