Clamping mechanism and method for laser drilling of artificial soft arterial stent

A vascular stent and laser drilling technology, applied in the direction of wound clips, etc., can solve the problems of large positioning errors and low drilling quality, and achieve the effects of high work efficiency, improved drilling quality, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

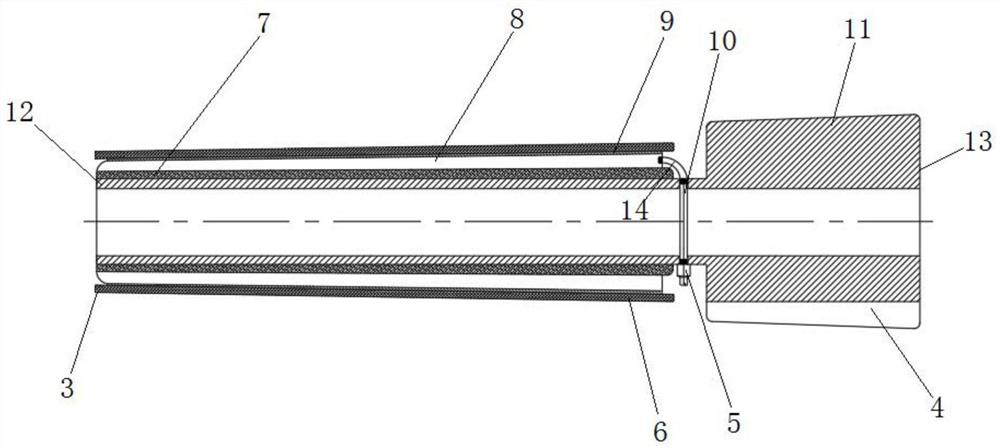

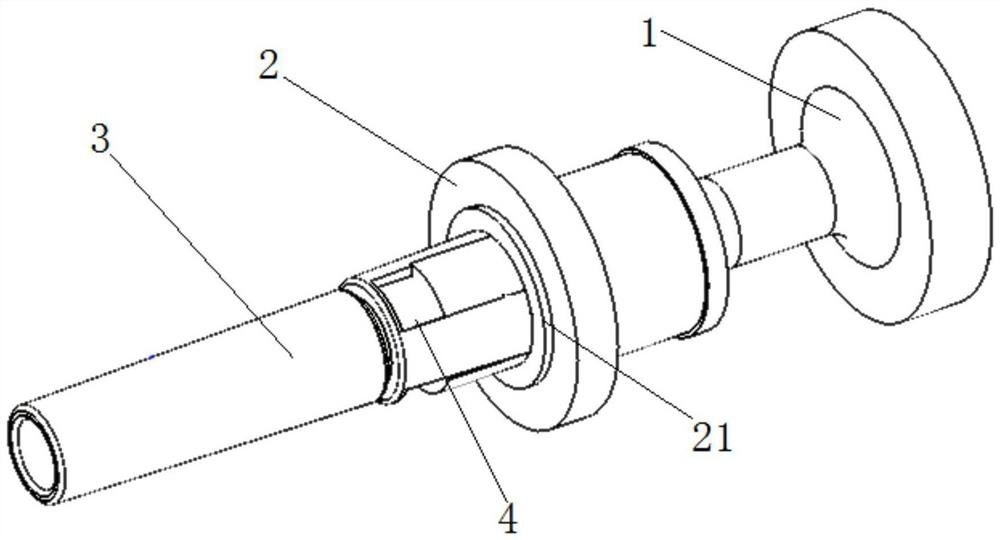

[0055] see Figure 1-5 , the present embodiment provides a clamping mechanism for laser drilling of an artificial soft arterial stent, which can be used as a laser drilling device for drilling holes on a thin-walled circular tubular artificial soft arterial stent. The clamping mechanism realizes the fixation and clamping operation of the artificial soft arterial stent during the laser drilling process of the thin-walled circular tubular artificial soft arterial stent, ensures the positioning error in the circumferential direction and the axial direction, and realizes the accurate laser drilling position. Wherein, the clamping mechanism is used to clamp a blood vessel stent 15 and includes a mounting base 1 , an electric clamping jaw 2 and a pneumatic elastic mandrel 3 .

[0056] A threaded hole for connecting an external device is provided on the mounting base 1 . When the laser drilling equipment does not have a corresponding clamping device, the mounting base 1 can be insta...

Embodiment 2

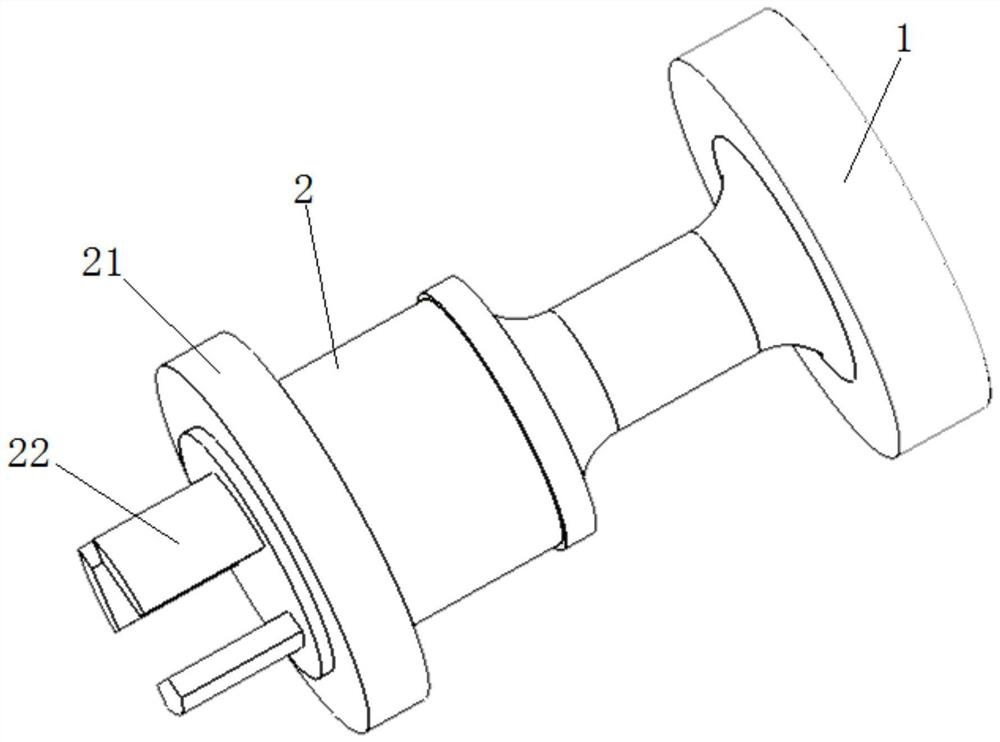

[0077] see Figure 6 This embodiment provides a clamping mechanism for laser drilling of artificial soft artery stents, which is similar to the clamping mechanism in Embodiment 1, except that the electric gripper 2 of this embodiment is an electromagnetically driven gripper. Wherein, each clamping arm 22 can be tightened in the electrified state, and the electric clamping jaw 2 clamps each clamping arm 22 in the corresponding clamping groove 4 . Each clamping arm 22 can be released when the power is off, and the electric clamping jaw 2 makes each clamping arm 22 disengage from the corresponding clamping groove 4 . The electrically driven jaws will drive each clamp arm 22 to tighten inwardly when energized, so that each clamp arm 22 is clamped in each clamping groove 4, and then can loosen the clamp arm 22 when the power is turned off, so that the electric clamp The claw 2 is separated from the pneumatic elastic core rod 3, and the clamping reliability of the electric clamp ja...

Embodiment 3

[0081] This embodiment provides a clamping method for laser drilling of an artificial soft artery stent, and the clamping method is applied to the clamping mechanism for laser drilling of an artificial soft artery stent in embodiment 1 or embodiment 2. Wherein, the clamping method includes the following steps.

[0082] 1. Determine whether the laser drilling equipment is equipped with a clamping device. Laser drilling equipment is used to drill thin-walled tubular artificial soft arterial stents to produce special medical devices.

[0083] 2. When the laser drilling equipment is equipped with a clamping device, place the mounting base 1 in the clamping device, and fix the electric gripper 2 on the platform of the laser drilling equipment.

[0084] 3. When the laser drilling equipment is not equipped with a clamping device, place the mounting base 1 below, place the pneumatic elastic mandrel 3 above and install it on an external rotary table.

[0085] 4. Set the vascular sten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com