A brushing device with dust removal function for steel structure coating

A technology for napping devices and steel structures, applied in the direction of grinding/polishing safety devices, manufacturing tools, metal processing equipment, etc., to achieve the effects of good portability, convenient use, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

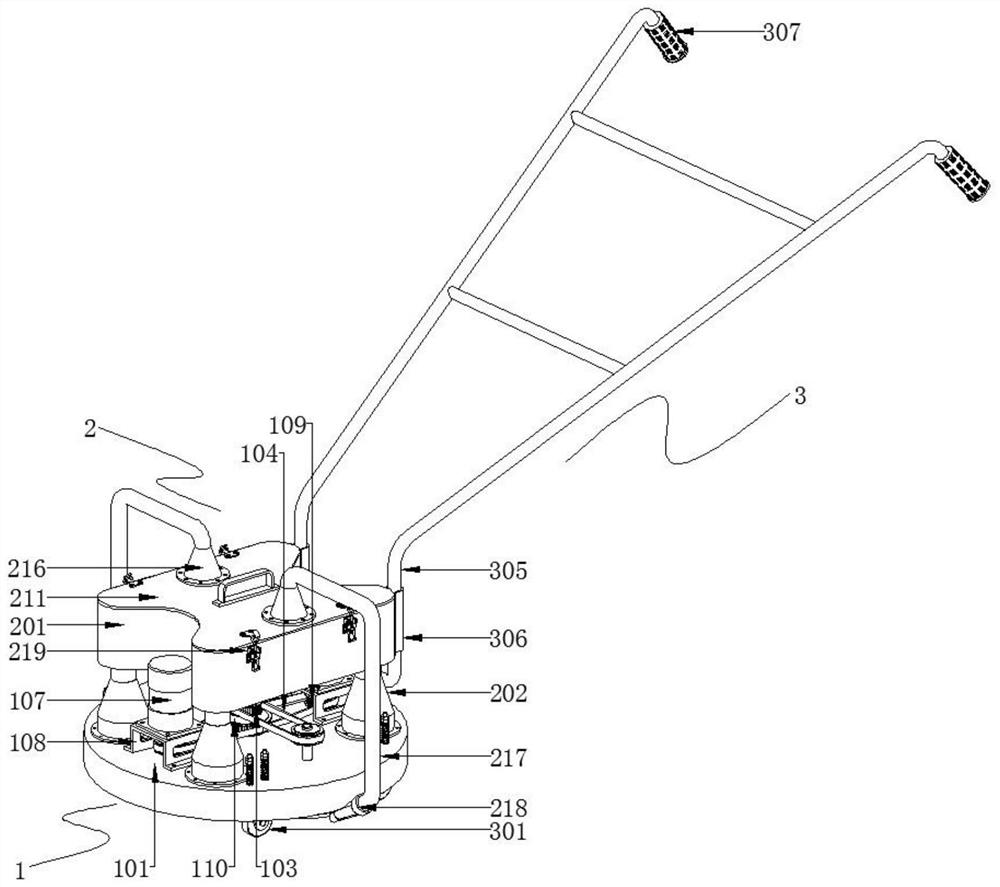

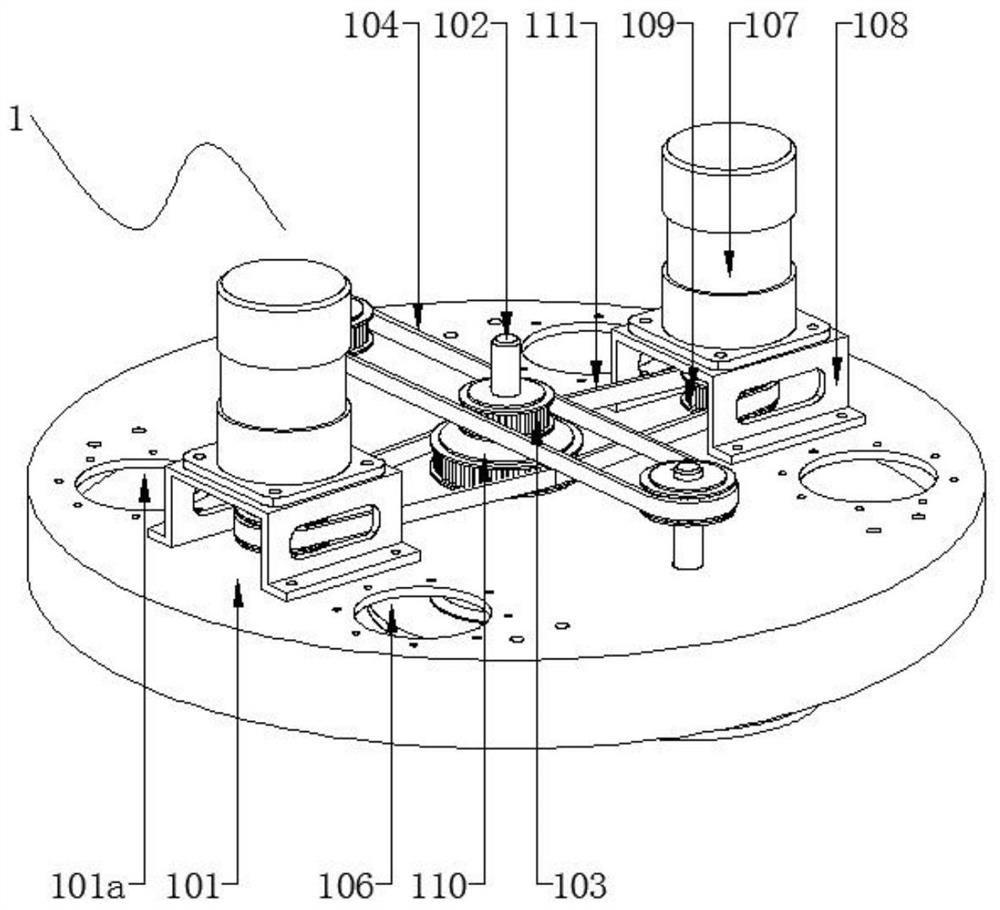

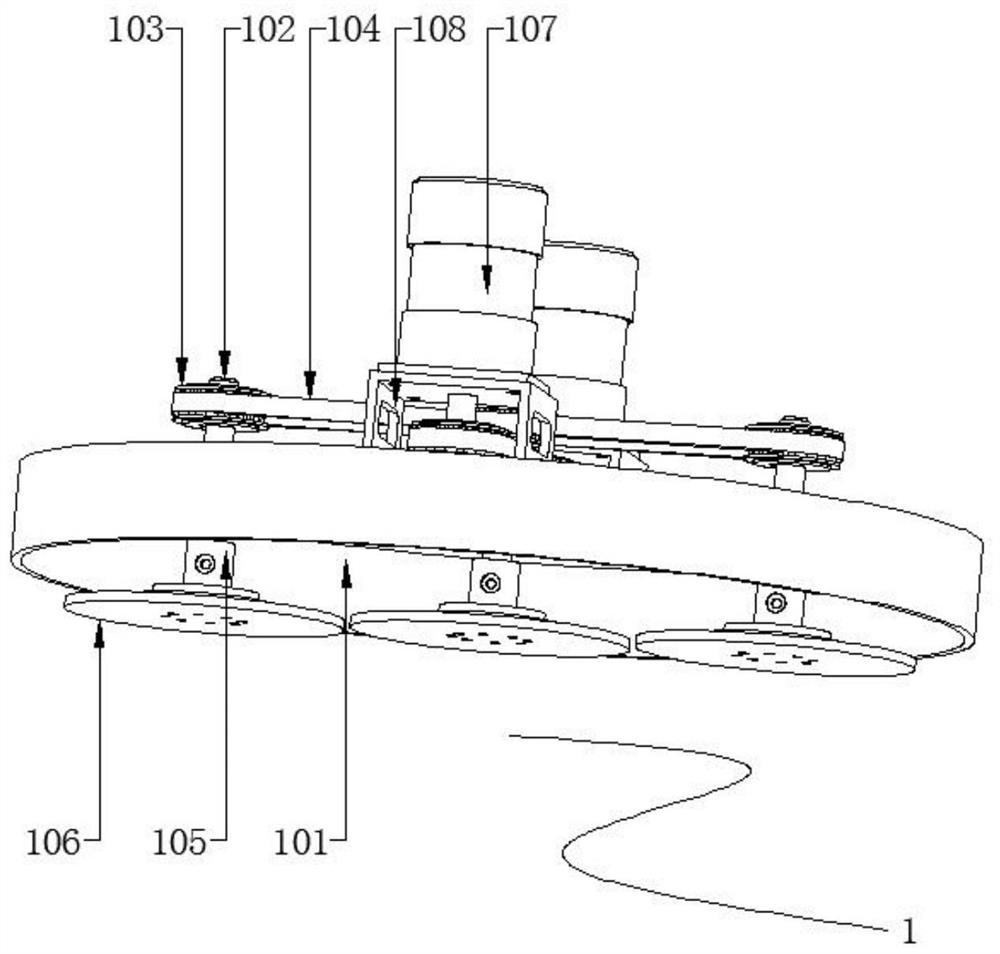

[0030] Such as Figure 1 to Figure 9 As shown, a napping device with dust removal function for steel structure coating, including napping assembly 1, dust removal assembly 2 and moving assembly 3;

[0031] The napping component 1 is used to realize the napping operation on the surface of the object in contact with it;

[0032] The dust removal assembly 2 is arranged above the napping assembly 1 and is used to absorb dust and debris generated by the napping assembly 1 during the napping operation;

[0033] The moving assembly 3 is arranged below the napping assembly 1 and is used to realize the movement of the napping assembly 1 during non-picking operations.

[0034] In the present invention, the napping assembly 1 includes a mounting cover 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com