Routing inspection robot control method, routing inspection system, storage medium and electronic device

A technology of inspection robots and control methods, applied in the field of robots, can solve problems such as multiple safety hazards and complex production environments, and achieve the effect of improving inspection efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

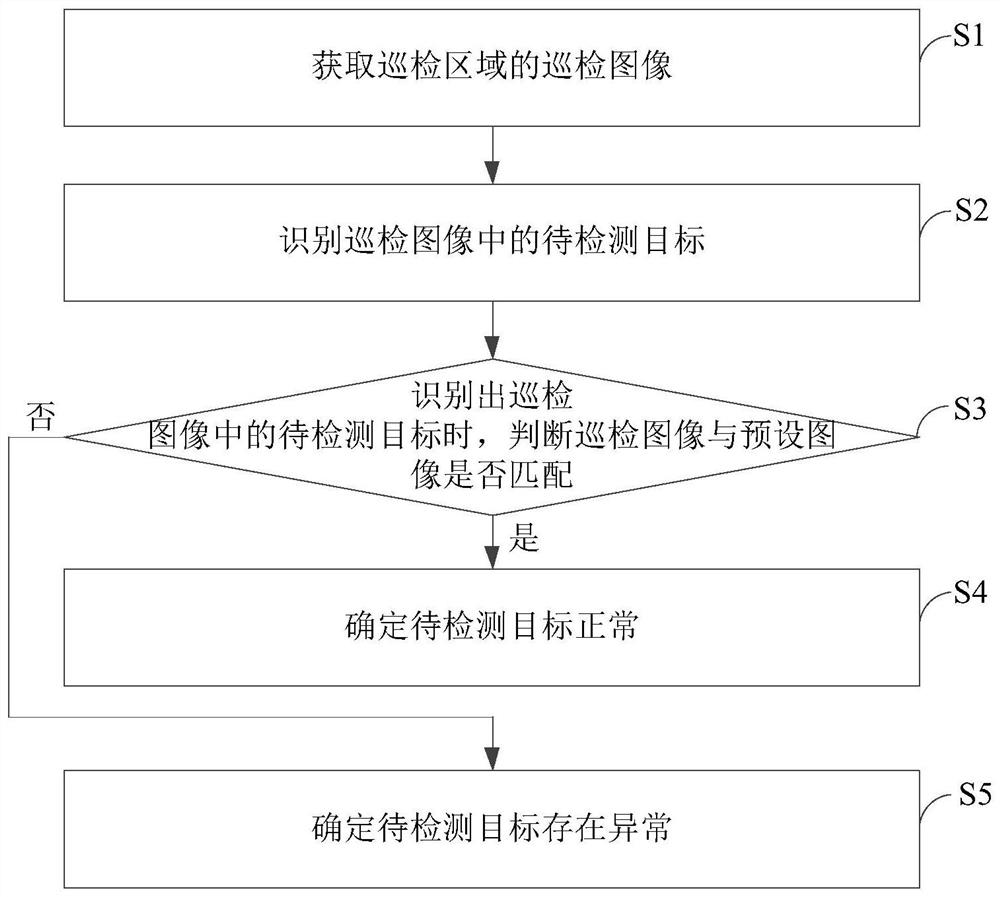

Embodiment 1

[0058] In order to solve the above-mentioned problems in the prior art, this embodiment provides a method for controlling an inspection robot, which can be applied to occasions requiring inspections such as factories and construction sites. Specifically, figure 1 It is a schematic flowchart of a method for controlling an inspection robot provided by an embodiment of the present invention. It should be noted that the method for controlling an inspection robot provided by an embodiment of the present invention does not use figure 1 And the specific order below is a limitation. It should be understood that in other embodiments, the order of some steps in the inspection robot control method provided by the embodiment of the present invention can be exchanged according to actual needs, or some of the steps can also be omitted or deleted. . This process can be executed by the processor of the inspection robot, can be executed by a server connected to the inspection robot, or can be ...

Embodiment 2

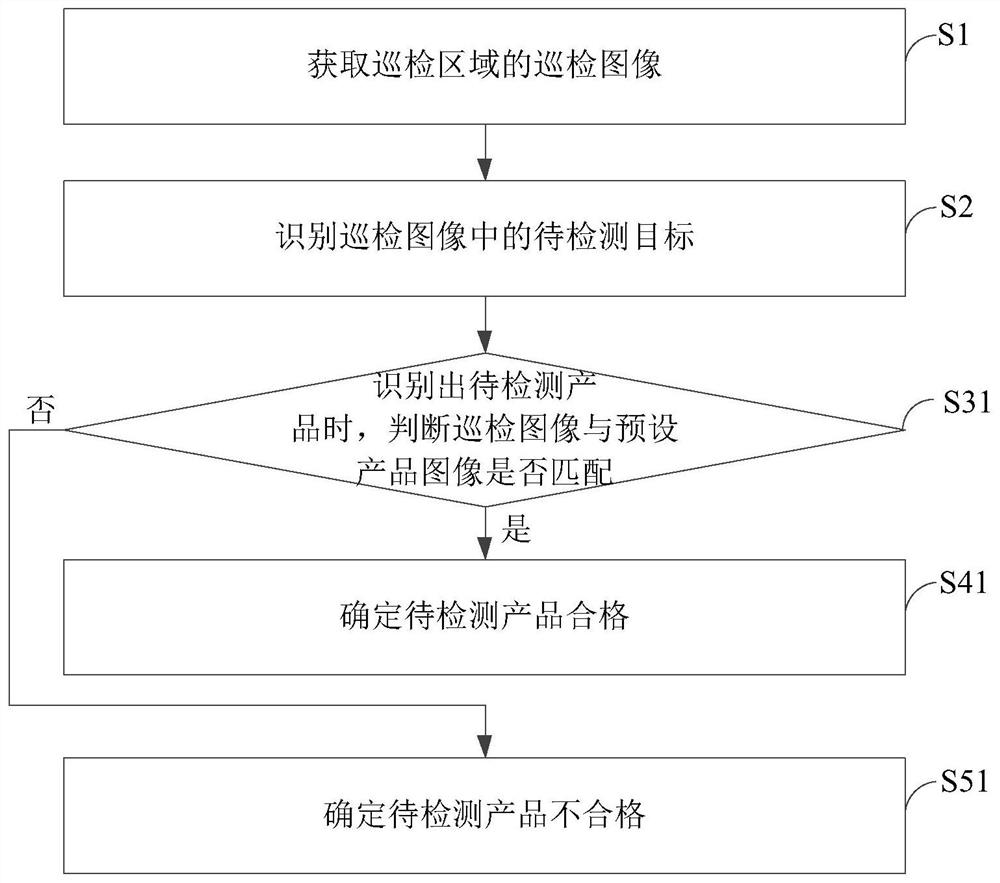

[0076] When the target to be detected includes a product to be detected, the preset image includes a preset product image, figure 2 For another schematic flowchart of a method for controlling an inspection robot provided by an embodiment of the present invention, please refer to figure 2 , step S3 includes:

[0077] Sub-step S31 , when the product to be detected is identified, it is judged whether the inspection image matches the preset product image.

[0078] Optionally, the preset product image may be an image of a qualified product. Wherein, the preset product images may be multiple, and may be images of qualified products collected from different angles.

[0079] If the inspection image matches the preset product image, the flow goes to step S41; if the inspection image does not match the preset product image, the flow goes to step S51.

[0080] It should be noted that if the inspection image does not match the preset product image, the product observed through the co...

Embodiment 3

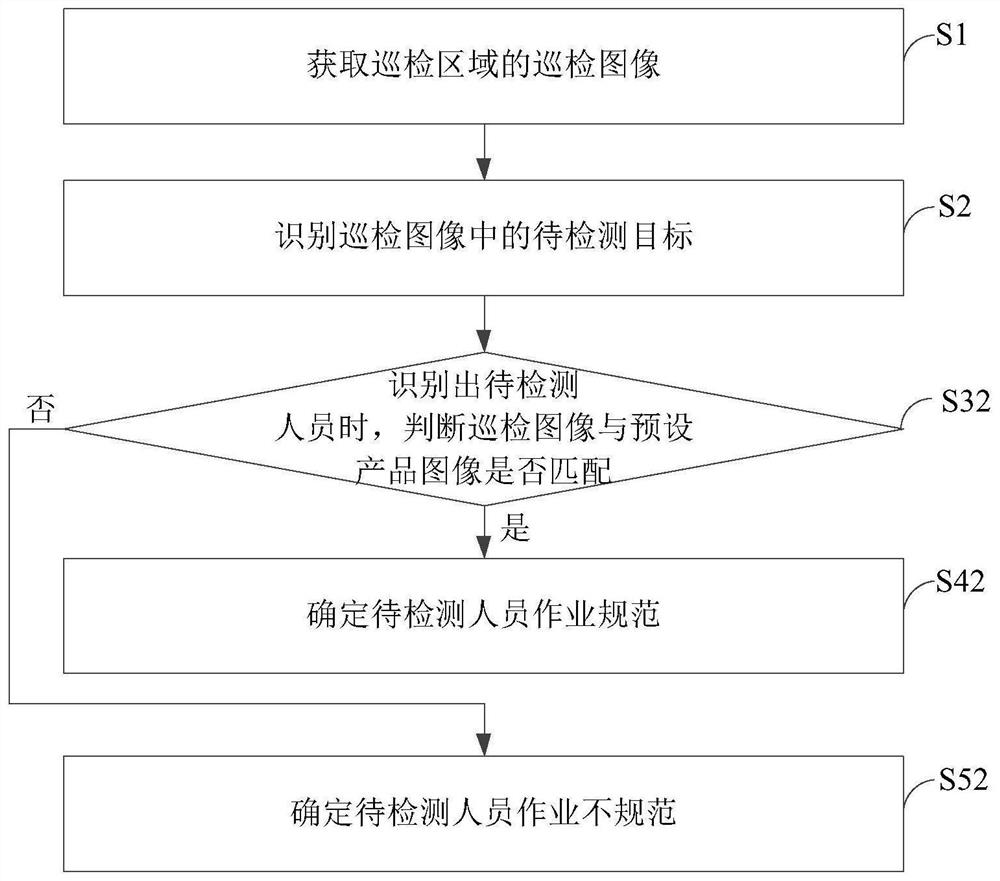

[0087] Similar to the previous embodiment, when the target to be detected includes a person to be detected, the preset image includes a preset person image, image 3 For another schematic flowchart of a method for controlling an inspection robot provided by an embodiment of the present invention, please refer to image 3 , step S3 includes:

[0088] Sub-step S32 , when the person to be detected is recognized, it is judged whether the inspection image matches the preset person image.

[0089] Optionally, the preset image of the person may be an image when the person operates in a standardized manner. Among them, the preset personnel images can be multiple, which can be images collected from different angles during the standard operation of the personnel; there can also be images of the personnel under different operations, for example, images under standard welding, standard placement The images of when it is released, the images under the standard handling materials, the ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com