Processing extrusion equipment for rubber anti-aging agent ZMMBI pre-scattering rubber master batch particles

A pre-dispersed masterbatch and rubber anti-aging agent technology, applied in the field of rubber anti-aging agent ZMMBI pre-dispersed masterbatch processing, can solve the problems of disintegration of master batches, unstable structure, uneven density of strip master batches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

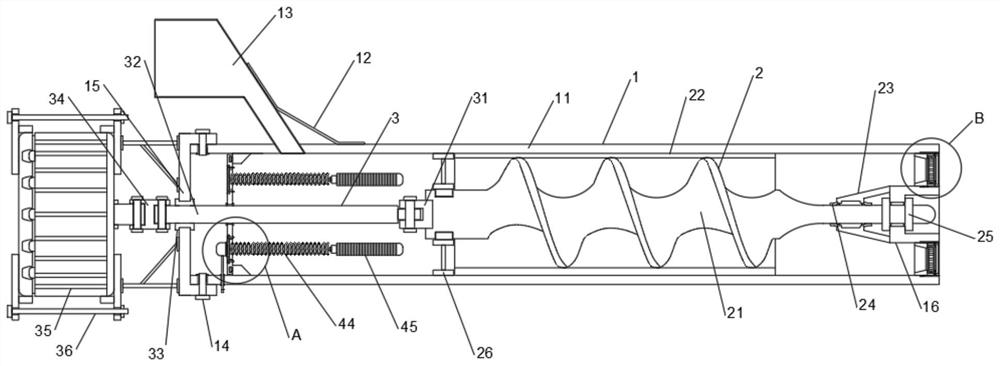

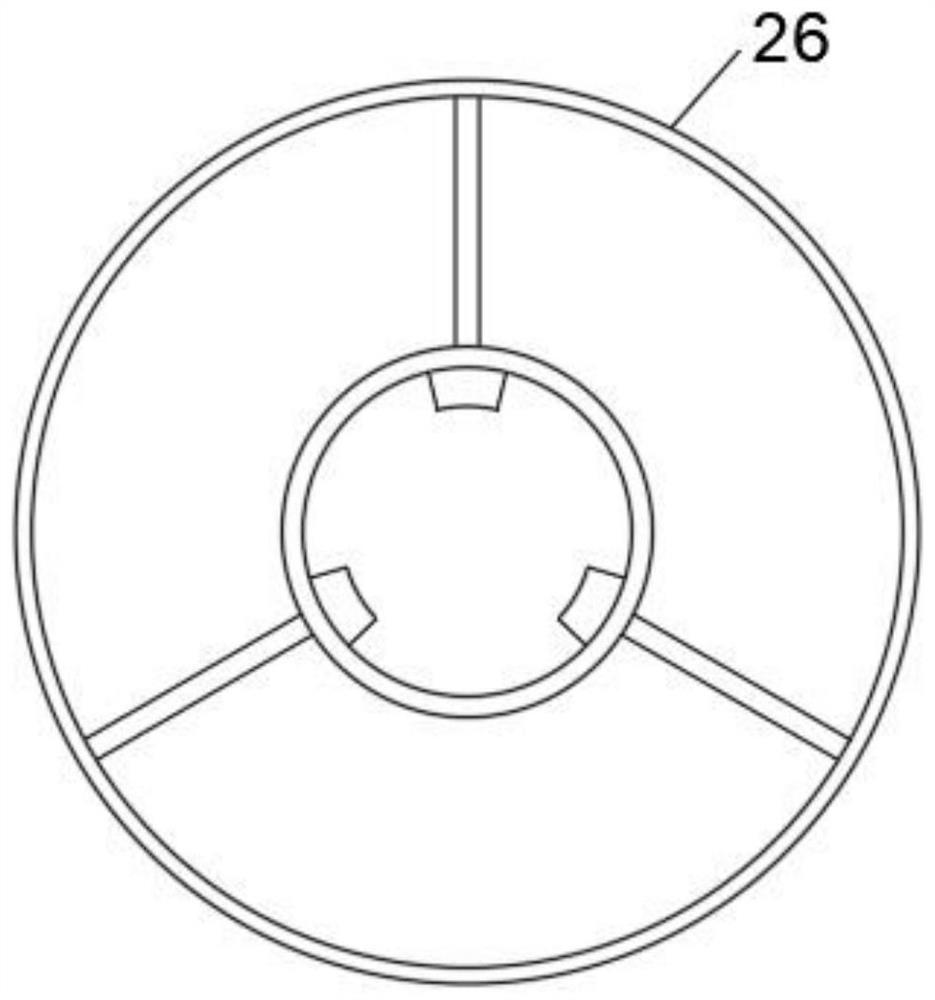

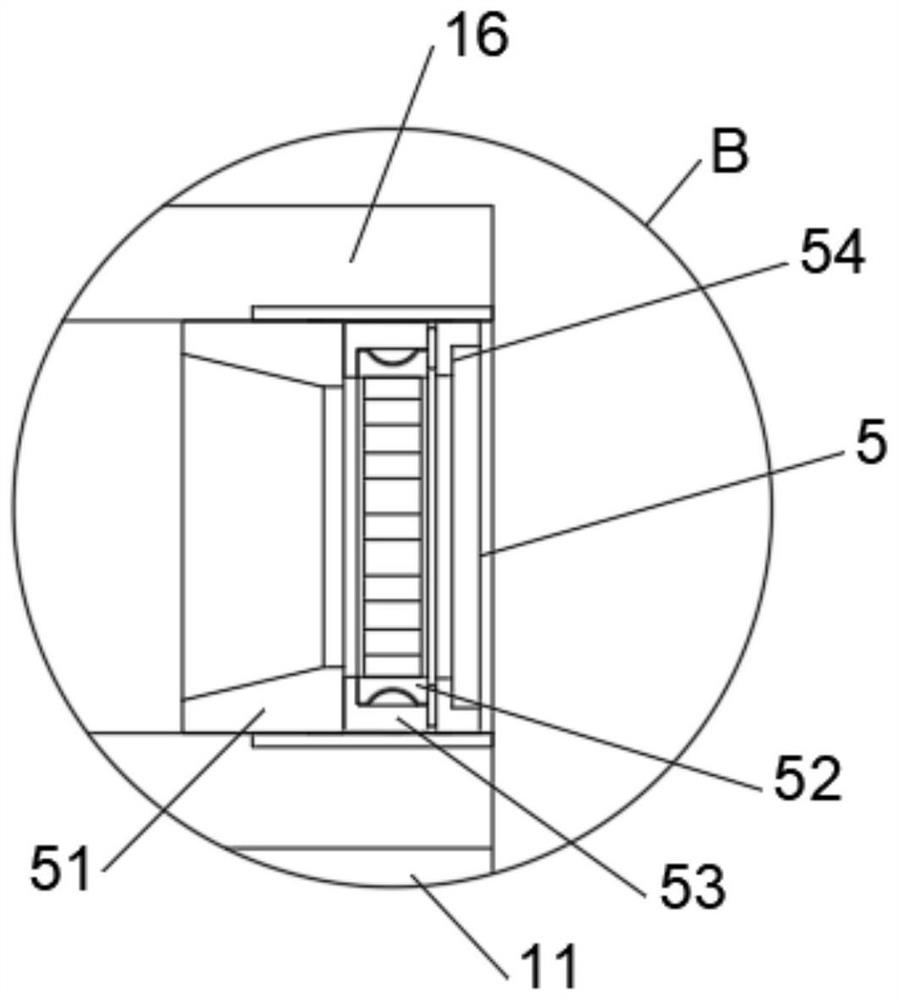

[0031] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a processing and extrusion equipment for rubber anti-aging agent ZMMBI pre-dispersed masterbatch particles, including a pipe body mechanism 1, and a screw extrusion mechanism 2 is arranged in the pipe body mechanism 1, One end of the screw extruding mechanism 2 is connected with a power mechanism 3, and a vibrating mechanism 4 is arranged between the power mechanism 3 and the screw extruding mechanism 2, and the vibrating mechanism is arranged between the pipe body mechanisms 1. An extruding mechanism 5 is arranged on the end of the extruding mechanism 2 away from the power mechanism 3;

[0032] The pipe body mechanism 1 includes a pipe 11, a feed hopper support 12 is fixedly connected to the outer wall of the pipe 11, and a feed hopper body 13 is fixedly connected to the top side of the feed hopper support 12, and the feed hopper body 13 is fixedly connected to the outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com