Color master batch with infrared reflection effect, sun-shading film and preparation method of sun-shading film

An infrared and color masterbatch technology, applied in the field of plastic coloring, can solve problems such as temperature rise, high temperature, and sunshade effect discount, and achieve the effect of reducing surface temperature and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

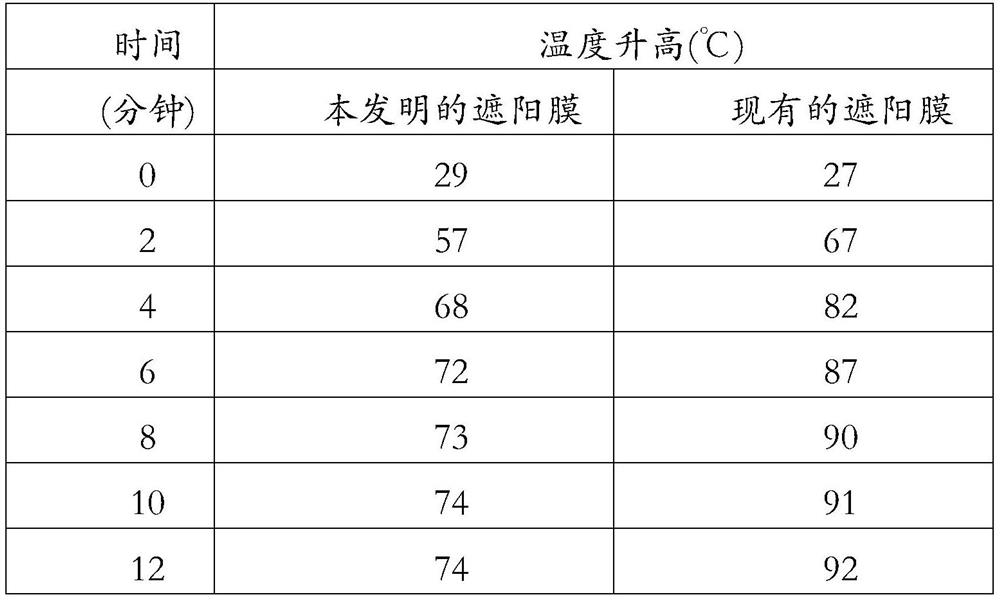

Examples

Embodiment 1

[0025] Under normal temperature and pressure, 16kg of cooling pigment yellow, 0.4kg of cooling pigment red, 5.1kg of cooling pigment black, 9.2kg of titanium dioxide, 3.4kg of ultraviolet absorber, 8.4kg of light stabilizer A, 4.4kg of antioxidant and polyethylene resin 45kg is sent to the mixer at a stirring speed of 100-120r / min for 30 minutes, stirring and mixing evenly to form a mixture. The mixture is put into a twin-screw extruder for extrusion granulation, and the extrusion temperature is controlled at 190-210°C. Extrude to form strands, then cool the strands through a water tank and enter the pelletizer for granulation to obtain the anti-aging and cooling masterbatch of the present invention.

Embodiment 2

[0027] Under normal temperature and pressure, 18kg of cooling pigment yellow, 0.5kg of cooling pigment red, 6.4kg of cooling pigment black, 10kg of titanium dioxide, 4kg of ultraviolet absorber, 9kg of light stabilizer A, 5kg of antioxidant and 46kg of polyethylene resin are sent to the mixer , the stirring speed is 100-120r / min, 30 minutes, stirring and mixing evenly into a mixture. The mixture is put into a twin-screw extruder for extrusion granulation, and the extrusion temperature is controlled at 190-210°C. Extrude to form strands, then cool the strands through a water tank and enter the pelletizer for granulation to obtain the anti-aging and cooling masterbatch of the present invention.

Embodiment 3

[0029] Under normal temperature and pressure, 20kg of cooling pigment yellow, 0.6kg of cooling pigment red, 7.6kg of cooling pigment black, 11.8kg of titanium dioxide, 4.6kg of ultraviolet absorber, 9.6kg of light stabilizer A, 5.6kg of antioxidant and polyethylene resin 48kg is sent to the mixer, the stirring speed is 100-120r / min, 30 minutes, stirring and mixing evenly to form a mixture. The mixture is put into a twin-screw extruder for extrusion granulation, and the extrusion temperature is controlled at 190-210°C. Extrude to form strands, then cool the strands through a water tank and enter the pelletizer for granulation to obtain the anti-aging and cooling masterbatch of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com