A bridge deck drainage structure

A drainage structure and bridge technology, which is applied in bridges, bridge construction, bridge parts, etc., can solve problems such as easy fracture of the joint between the branch pipe and the main pipe, impact of the branch pipe, shaking of the branch pipe, etc., to achieve smooth flow, reduce impact force, avoid cracked or damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

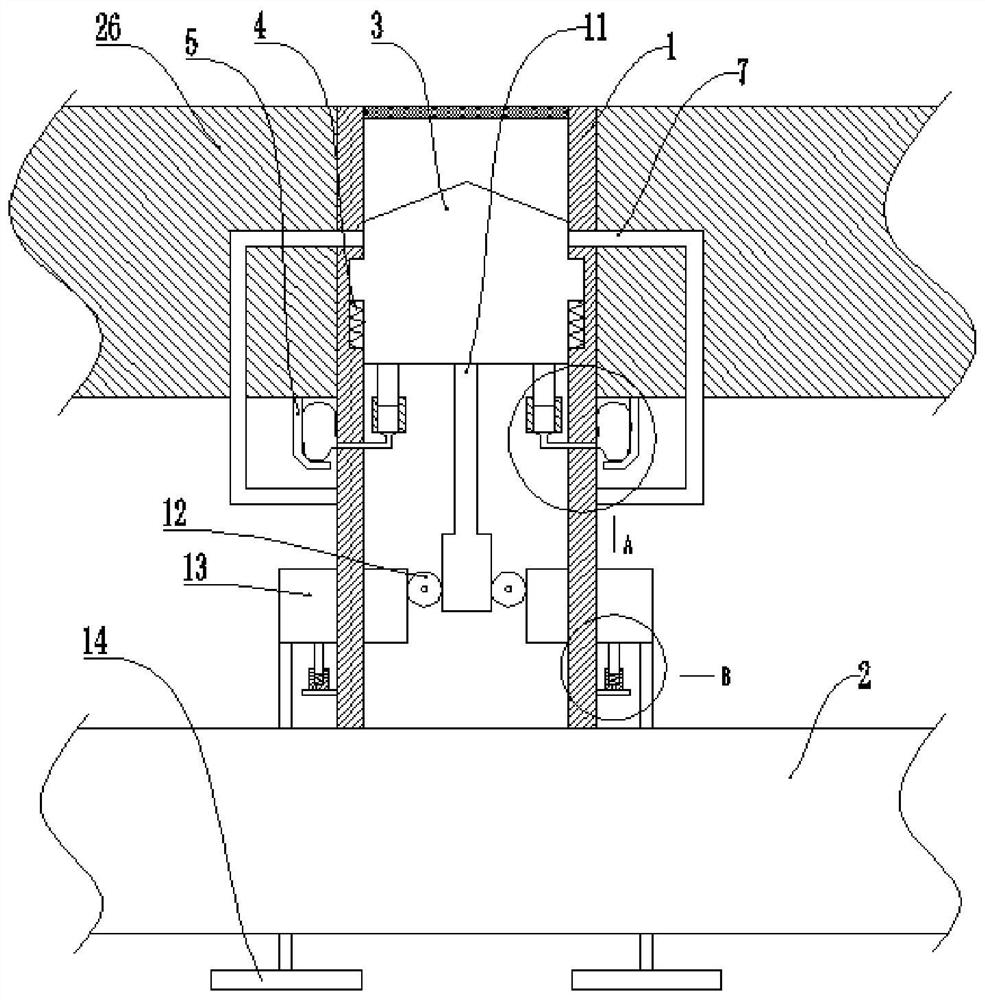

[0038] Basic as attached figure 1 , attached figure 2 And attached image 3 Shown: a bridge deck drainage structure, including several branch pipes 1 fixed on the bridge 26 and main pipes 2 connected to several branch pipes 1, and the top of the branch pipes 1 is equipped with a filter screen, and the main pipe 2 is located below the branch pipes 1.

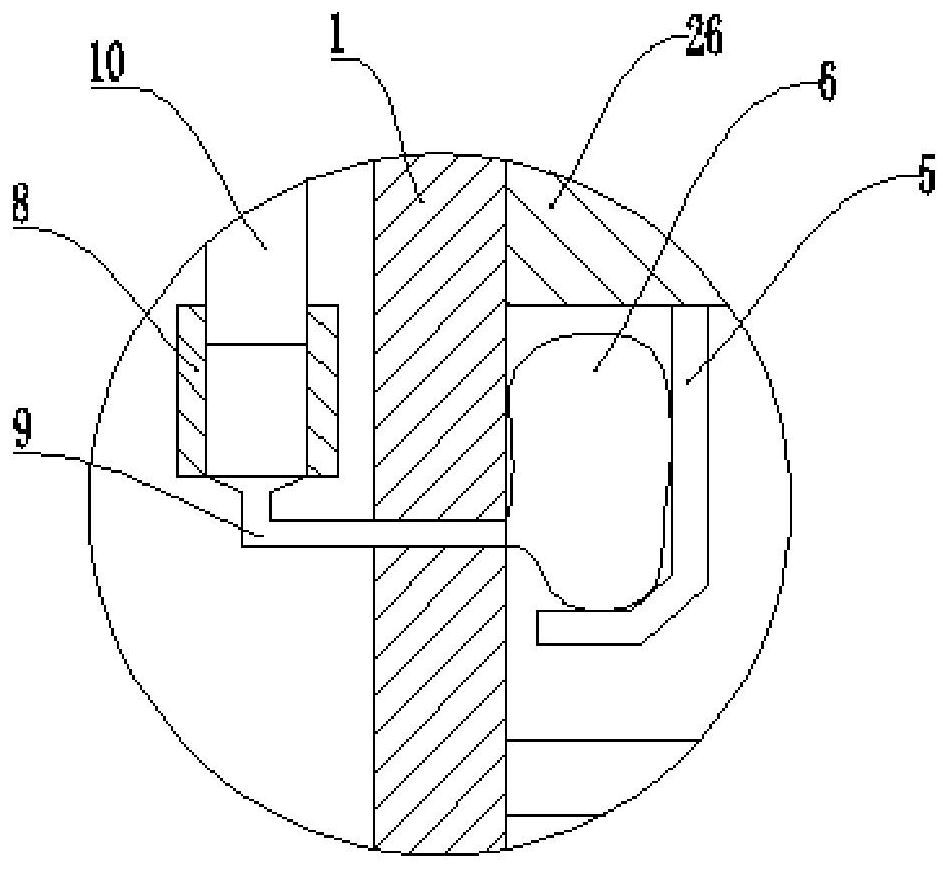

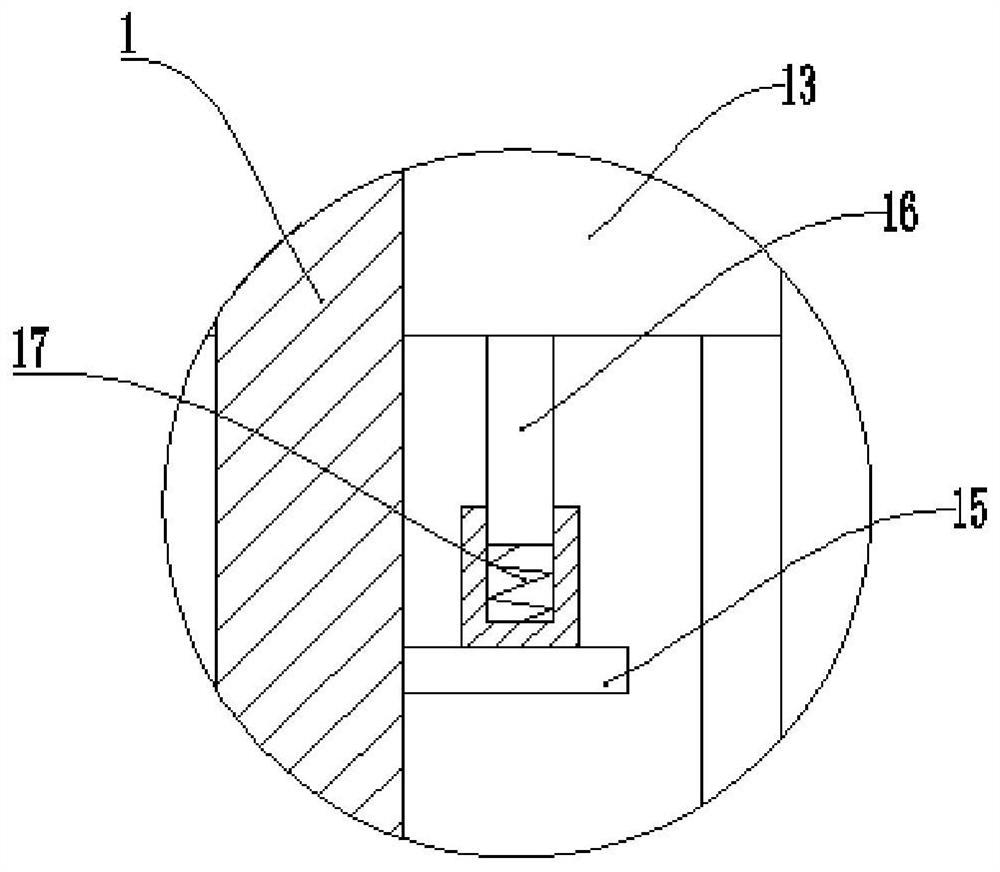

[0039] An annular groove is vertically formed on the inner wall of the branch pipe 1, and a slider 3 is vertically slidably connected in the annular groove, and a first spring 4 is fixedly connected between the slider 3 and the annular groove, and the top of the slider 3 is conical. It also includes a stabilizing mechanism arranged symmetrically along the centerline of the slider 3. The stabilizing mechanism includes a stopper 5, an airbag 6 located between the branch pipe 1 and the stopper 5, and an inflatable part that inflates the airbag 6 as the slider 3 moves vertically. The block 5 is fixed on the bridge 26 by bolts. The...

Embodiment 2

[0049] Basic as attached Figure 4 , attached Figure 5 And attached Figure 6 As shown: the structure and implementation of Embodiment 2 are basically the same as Embodiment 1, the difference is that: it also includes a collection box 18 fixed at the bottom of the bridge 26 by bolts, and the side wall of the side pipe 7 is communicated with a collection pipe 19 , and the collection pipe 19 communicates with the collection box 18; the side pipe 7 is fixedly connected with a screen 20, and the end of the collection pipe 19 away from the collection box 18 is located above the screen 20.

[0050] In the collecting box 18, a lifting plate 21 is vertically slidably connected, and a third spring 22 is fixedly connected between the lifting plate 21 and the collecting box 18. There is a discharge port above the right side wall of the collecting case 18, and the discharge port is located at Lifting plate 21 tops. The bottom of the lifting plate 21 extends downwards with a spheroid 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com