Auxiliary device for hitting ultralong steel pipe pile and application method thereof

An auxiliary device, a technology of steel pipe piles, applied in sheet pile walls, construction, infrastructure engineering, etc., can solve the problems of cumbersome operation process, inaccurate control of the verticality of steel pipe piles, etc., and achieve the effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

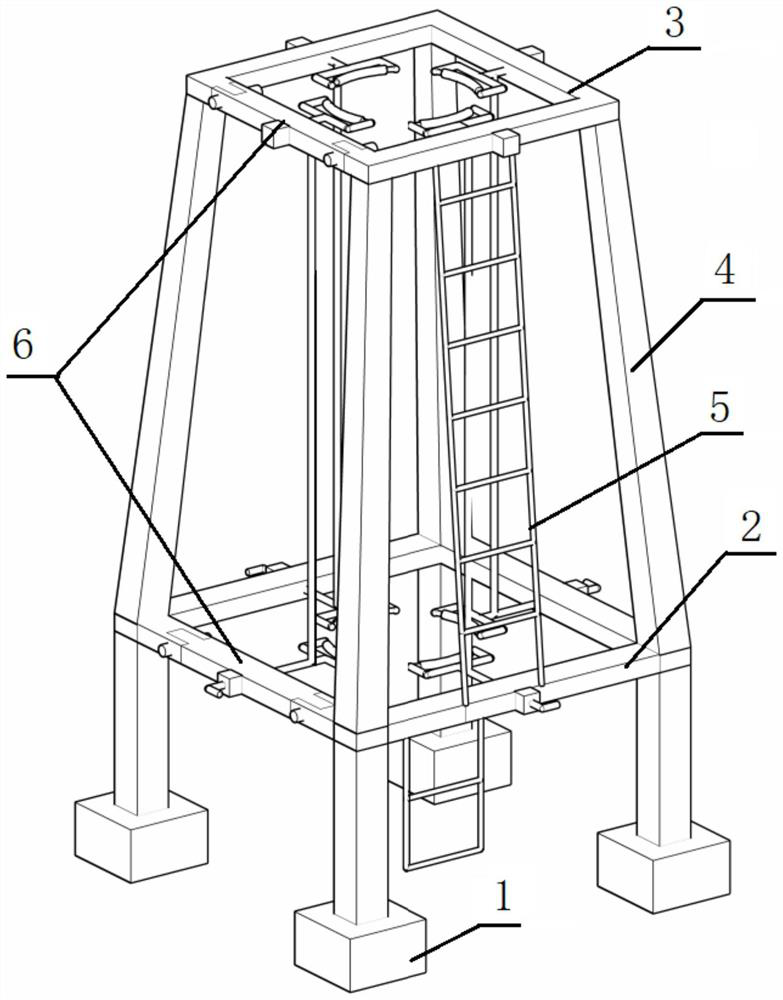

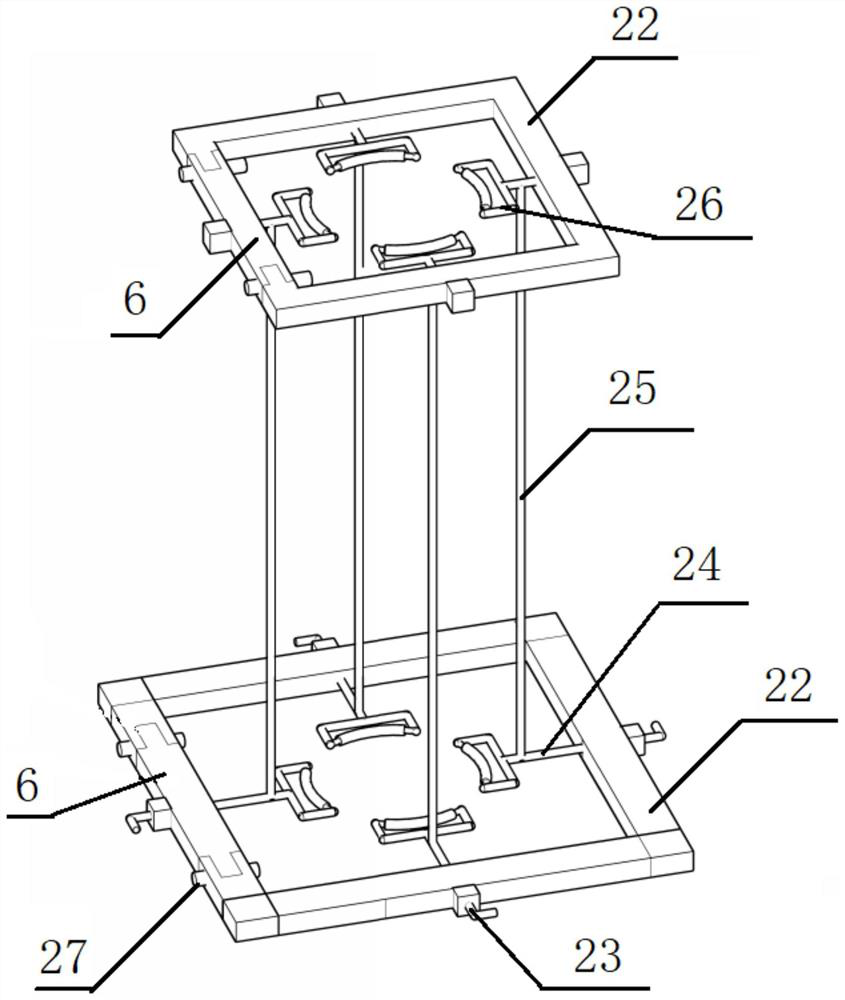

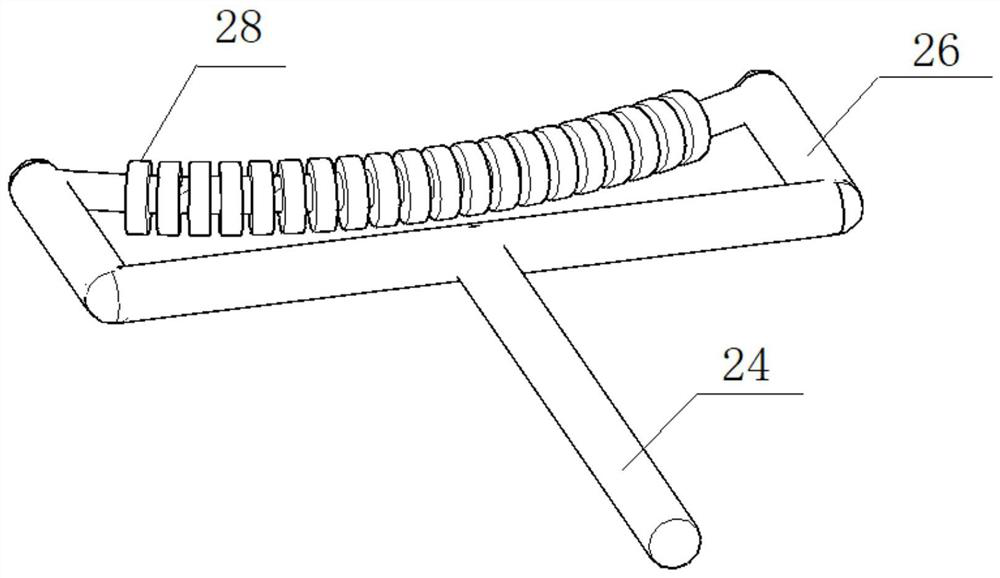

[0039] refer to Figure 1 to Figure 3 , the present application provides a super-long steel pipe pile driving auxiliary device (referred to as "auxiliary device") and its use method, including: a base 1; a lower wellhead mechanism 2, which is detachably connected to the base 1, and the The central clamping space of the lower wellhead mechanism 2 is adjustable; the upper wellhead mechanism 3 is connected to the lower wellhead mechanism 2, and the central clamping space of the upper wellhead mechanism 3 is adjustable; wherein, the central clamping space is adjustable The lower wellhead mechanism 2 and the upper wellhead mechanism 3 are used to clamp the super-long steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com