Full-quadrant driving wheel train with universal transmission structure

A universal transmission, traveling wheel technology, applied in the direction of wheels, vibration suppression adjustment, springs/shock absorbers, etc., to achieve the effect of highly flexible changes in load bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

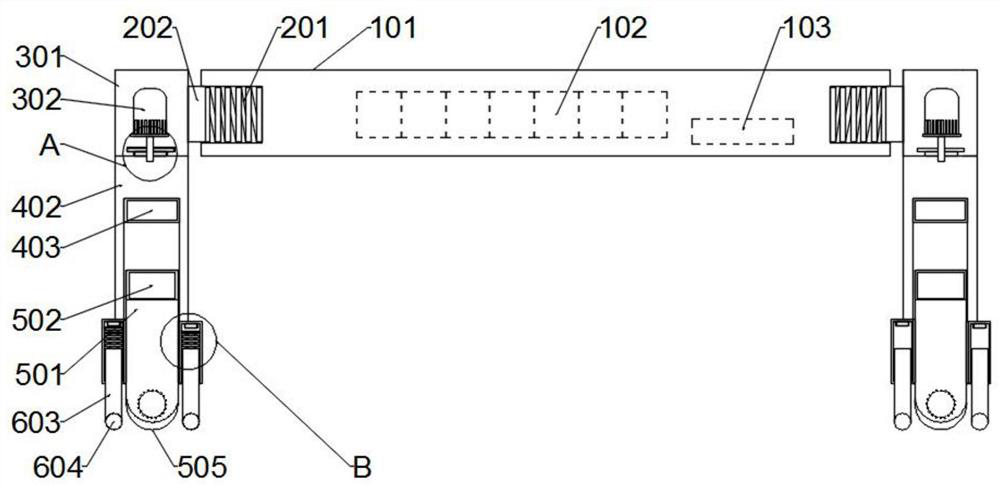

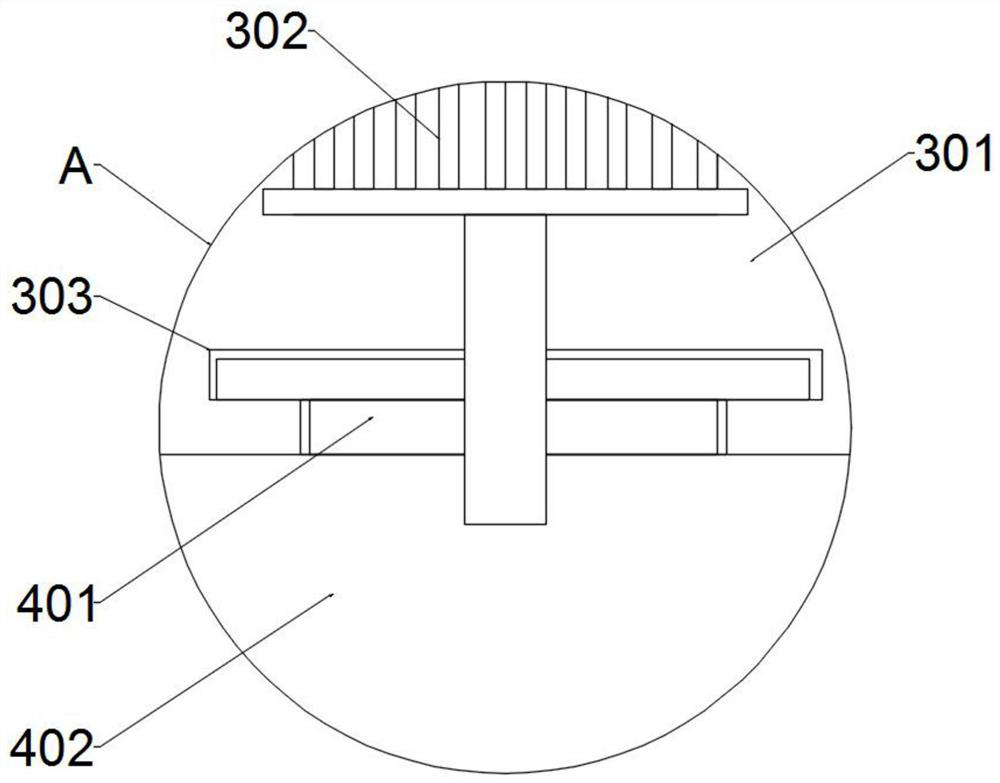

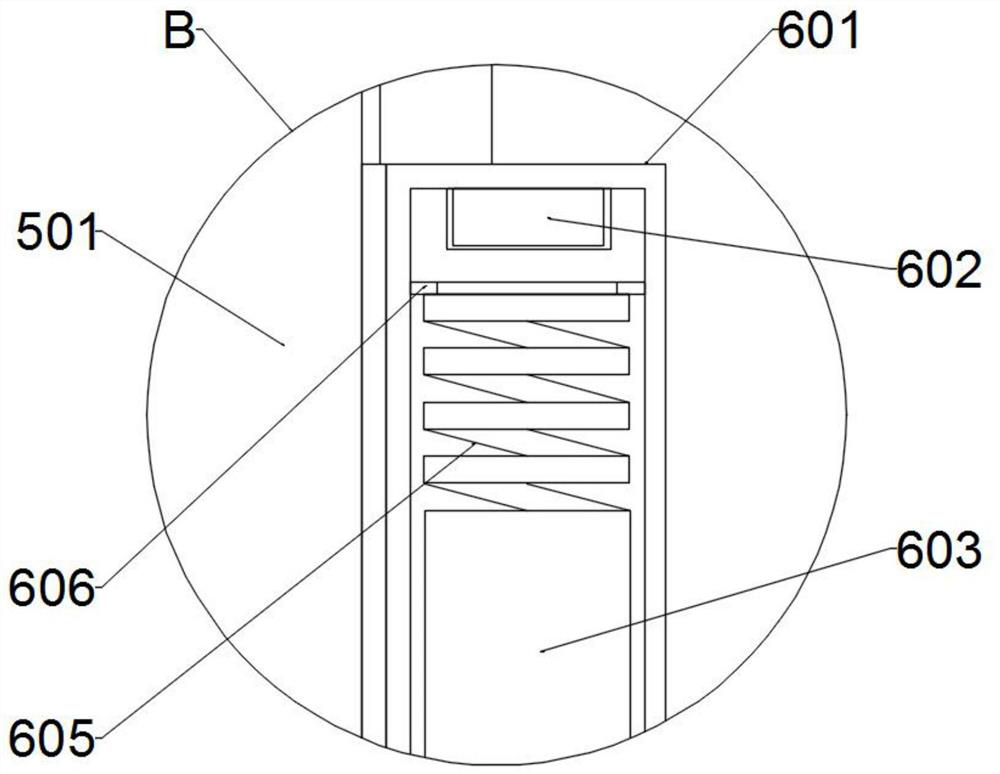

[0024] Example: such as Figure 1-4 As shown, the full-quadrant driving wheel train with a universal transmission structure includes a load-bearing component, a lateral anti-vibration component, a universal component, an upper lifting component, a lower lifting component, and a detection component. For the function of carrying external objects, the four corners of the bearing component are equipped with horizontal anti-vibration components, which can reduce the impact vibration caused by lateral obstacles to the device. It plays the role of controlling the rotation of the device in any direction. The lower end of the universal assembly is provided with an upper lifting assembly. The upper lifting assembly plays the role of supporting the upper part. The lower end of the upper lifting assembly is provided with a lower lifting assembly. The lower lifting assembly acts as a lifting control device. Depending on the height, the lower end of the lower lifting component is provided w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap