Flexible graphite gasket with V-shaped with inner ring and outer ring with V-shaped protrusions

A flexible graphite, inner and outer ring technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of loss of sealing performance, loss of flexible graphite, etc., and achieve the effect of maintaining sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

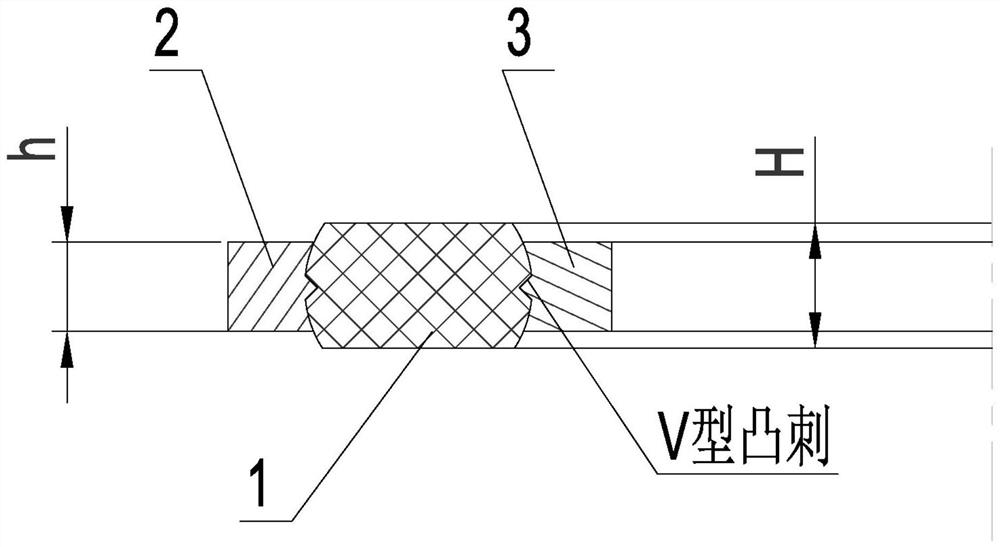

[0016] Below in conjunction with accompanying drawing, the application is further described:

[0017] As shown in the attached figure, a flexible graphite gasket structure with a V-shaped protruding inner and outer ring is composed of an inner ring, an outer ring and flexible graphite. The inner ring and the outer ring are made of metal, and each has a concave Arc, with a V-shaped thorn, the height of the V-shaped thorn is about 2mm, and the thickness h of the inner and outer rings is 70% to 80% of the thickness H of the flexible graphite to control the appropriate amount of flexible graphite compression , between the inner ring and the outer ring is flexible graphite, and the flexible graphite, the inner ring and the outer ring are pressed to form an integral gasket.

[0018] The technical characteristics of realizing the present invention are: because the flexible graphite is pressed between the inner ring and the outer ring, and due to the relationship between the concave a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com