Stator for a motor or electromagnetic generator with individual winding support snap-fitted to an associated tooth

An electromagnetic generator, winding support technology, applied in the manufacture of motor generators, motor components, windings, etc., to achieve the effect of increasing convenience, expanding the scope of use, and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

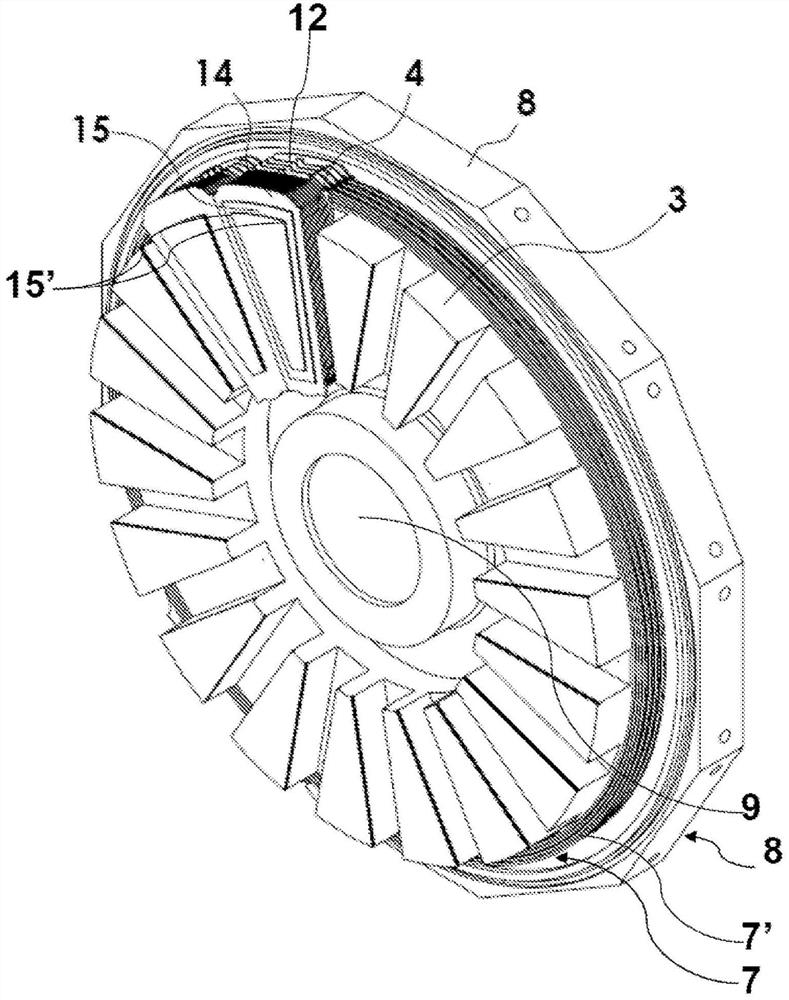

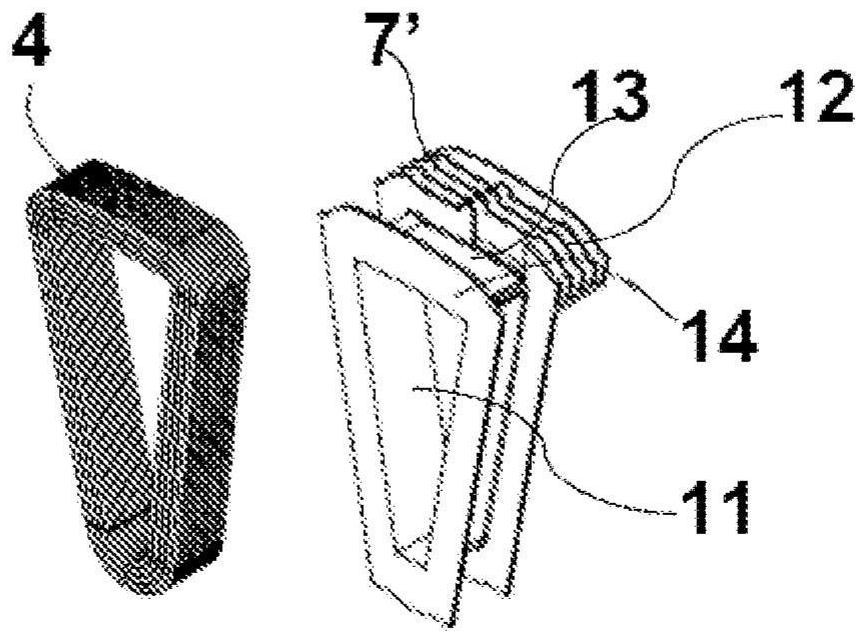

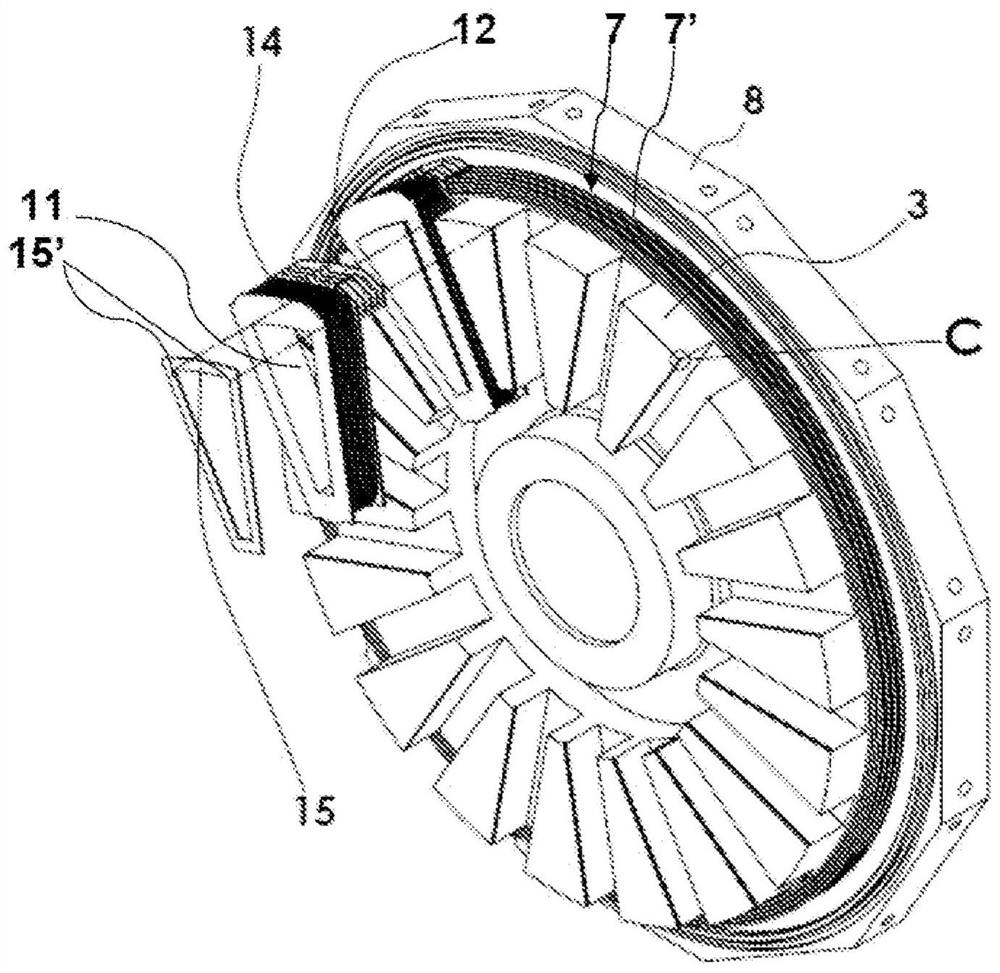

[0074] For the first embodiment, the associated tooth 3 may comprise a slot near each side edge of its face facing the winding 4, two slots 3' each receiving one of the snap-fit parts and forming a complementary snap fit. Snap fit means 3'. The slots 3' may preferably extend over the laterally inclined surfaces of the teeth 3, but not necessarily over the surfaces of the teeth facing the windings.

[0075] This is valid for all winding supports 4 and all teeth 3 . The flat cover portion 14 associated with a tooth 3 may be adjacent to the flat cover portion 14 associated with each adjacent tooth 3 . A set of cover parts can then form a ring which completely covers the teeth 3 and the spaces separating them.

[0076] The teeth 3 can be made of iron or ferrite plastomer, while the winding support 4 can be made of strong plastic material. Each tooth 3 may be formed from coiled or laminated sheet metal.

[0077] The locking element 15 (when present) is advantageously met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com