A jaw plate manufacturing device and method for misaligned orthodontics

A technology for manufacturing devices and orthodontics, which is applied in manufacturing auxiliary devices, orthodontics, medical science, etc., can solve the problems of poor repeatability and low precision, and achieve the effect of simple operation, guaranteed repeatability, and improved manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

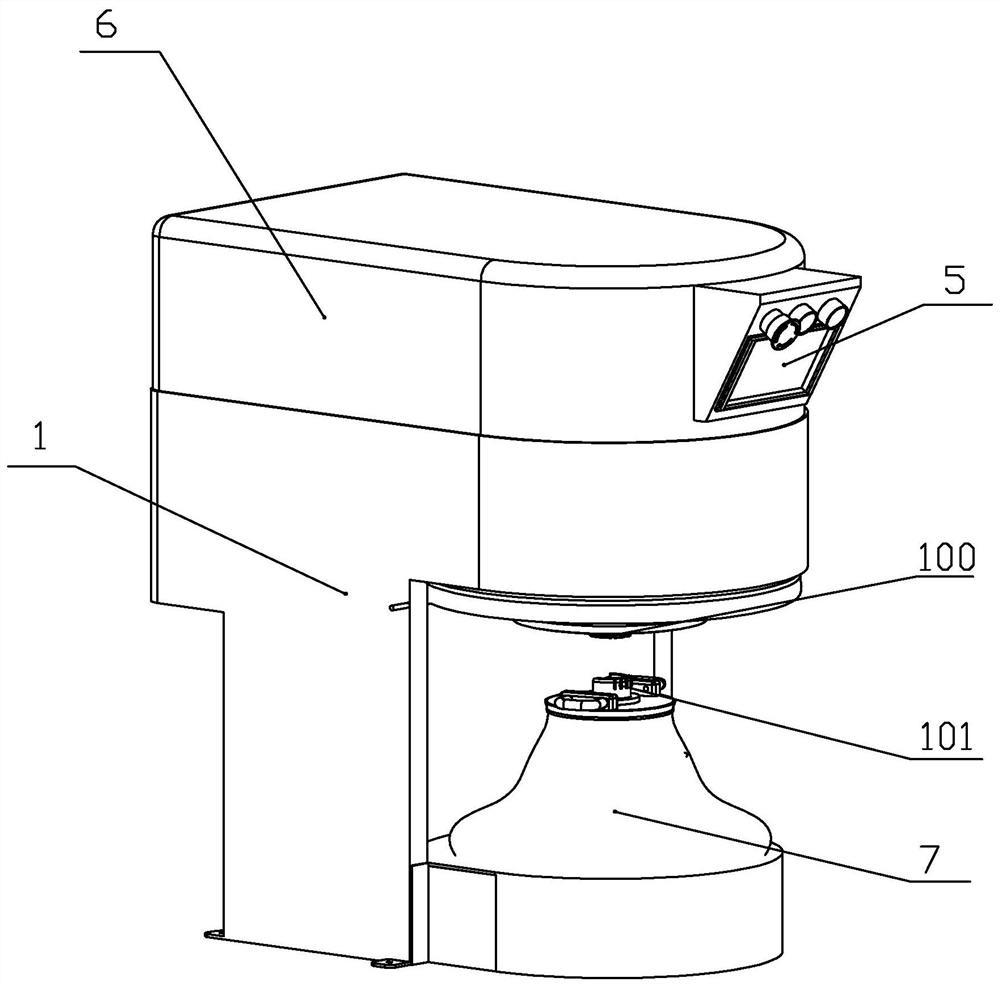

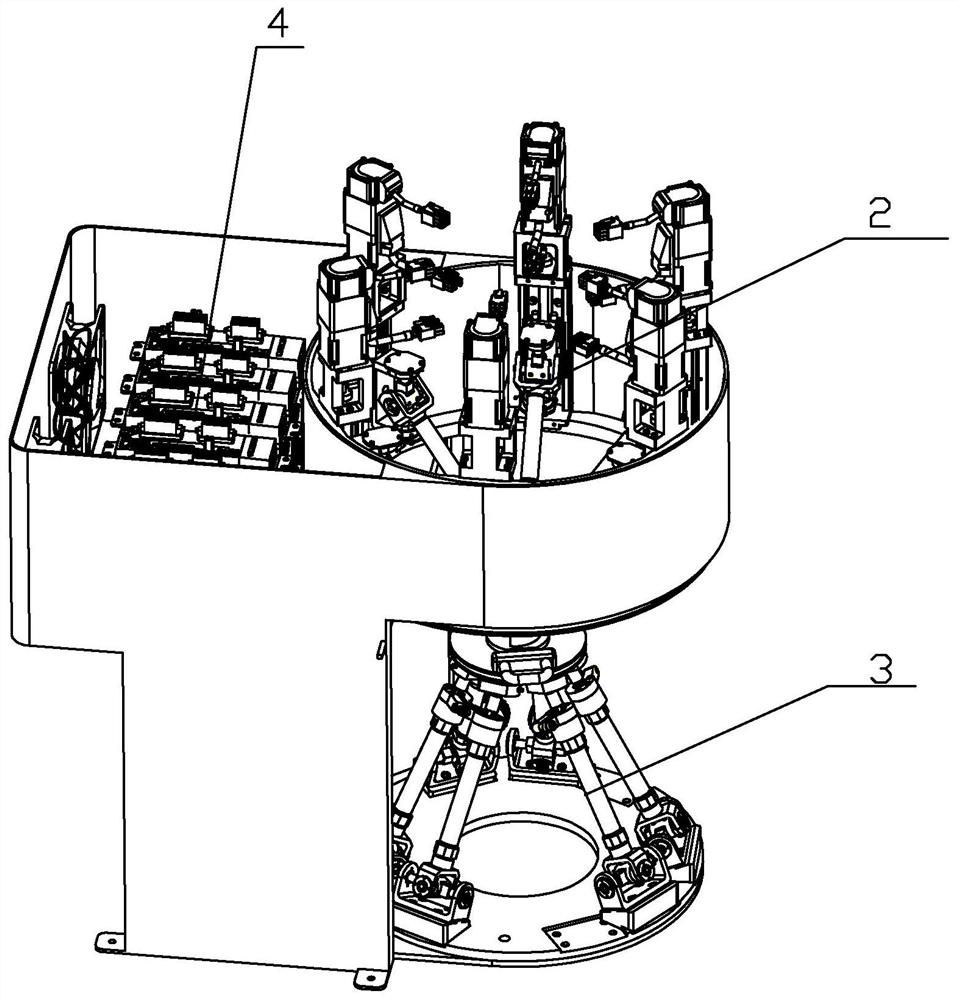

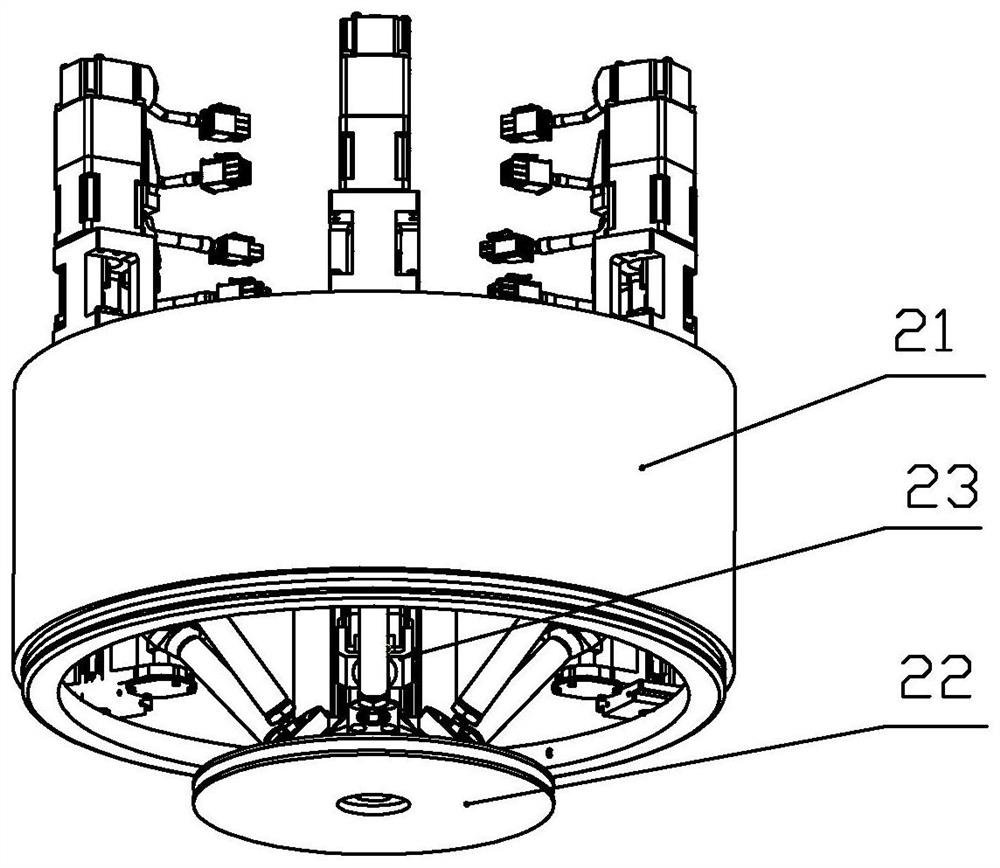

[0038] Specific implementation mode one: combine Figure 1-7 Describe this embodiment, a jaw plate manufacturing device for misaligned occlusion orthodontics, which includes a basic frame 1, an active parallel mechanism 2 and a passive parallel mechanism 3, and the active parallel mechanism 2 includes an active parallel installation base 21, an active parallel mechanism The parallel moving plate 22 and the first position adjustment assembly 23, wherein the first position adjustment assembly 23 is fixedly installed on the upper part of the base frame 1 through the active parallel installation base 21, and the active parallel moving plate 22 is fixed at the first position The bottom end of the adjustment assembly 23 realizes six degrees of freedom movement through the first position adjustment assembly 23. The passive parallel mechanism 3 includes a passive parallel installation base 31, a passive parallel moving plate 32 and a second position adjustment assembly 33, wherein the ...

specific Embodiment approach 2

[0048] Specific implementation mode two: combination Figure 1-7 Describe this embodiment, a kind of manufacturing method that adopts above-mentioned jaw plate manufacturing device for malocclusion orthodontics, it comprises the following steps:

[0049] Step 1. Scan the upper and lower teeth of the patient through CT filming technology, obtain the relevant parameters of the patient's tooth position, and make the original occlusal jaw plate;

[0050] Step 2. Use 3D printing to print the patient's upper and lower dental models (ie: make a dental model according to the actual position of the patient's teeth at 1:1);

[0051] Step 3. Fix the upper dental model on the active parallel moving plate, fix the lower dental model on the passive parallel moving plate, control the active parallel mechanism to stop at zero position (that is, keep the position after the active parallel mechanism is electrically homed), Manually push the passive parallel mechanism to drive and adjust the re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap