Impact type soaking cleaning oil basin of heavy truck filter screen

A filter and impact type technology, which is applied in the direction of fuel air filter, filter regeneration, filter separation, etc., can solve the problems of low disassembly efficiency, increased staff fatigue, low filter efficiency, etc., to achieve The effect of improving disassembly efficiency and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

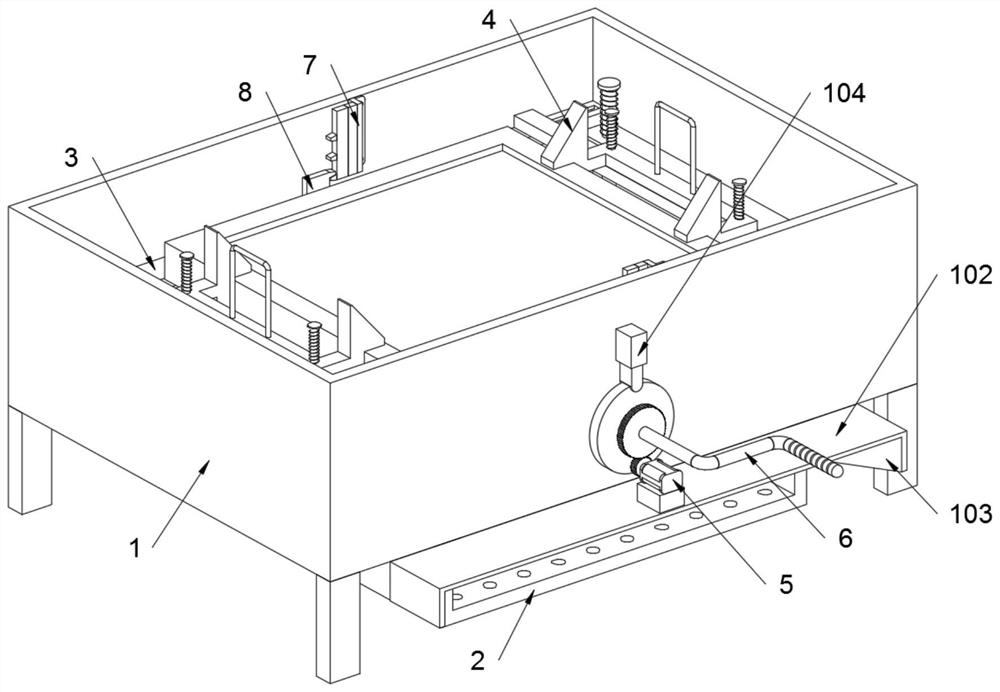

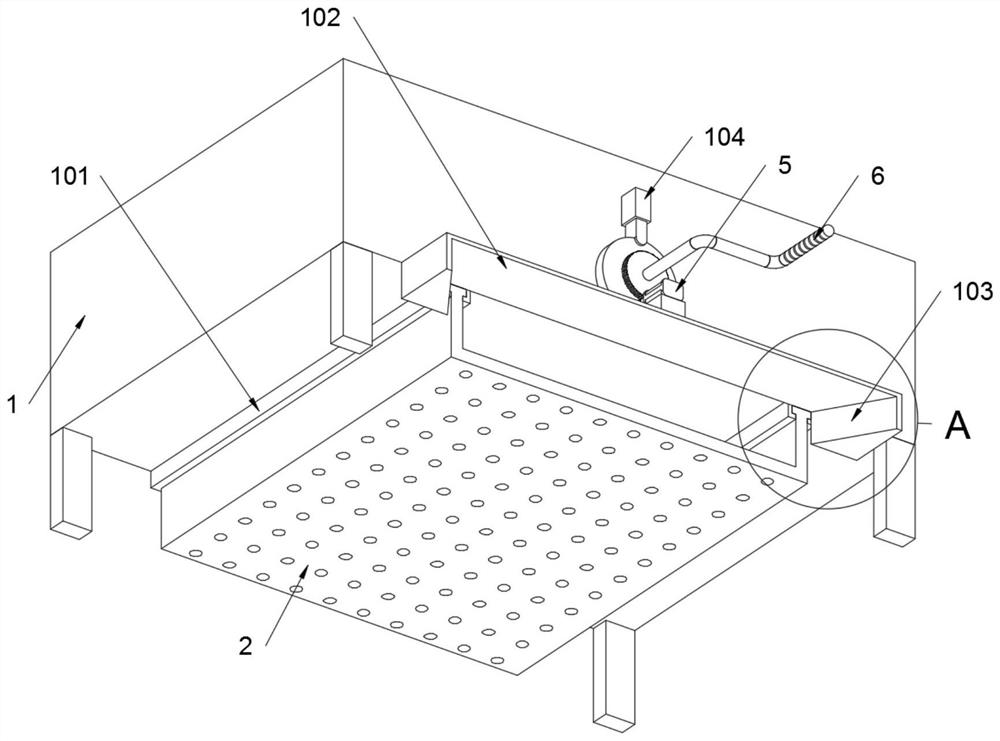

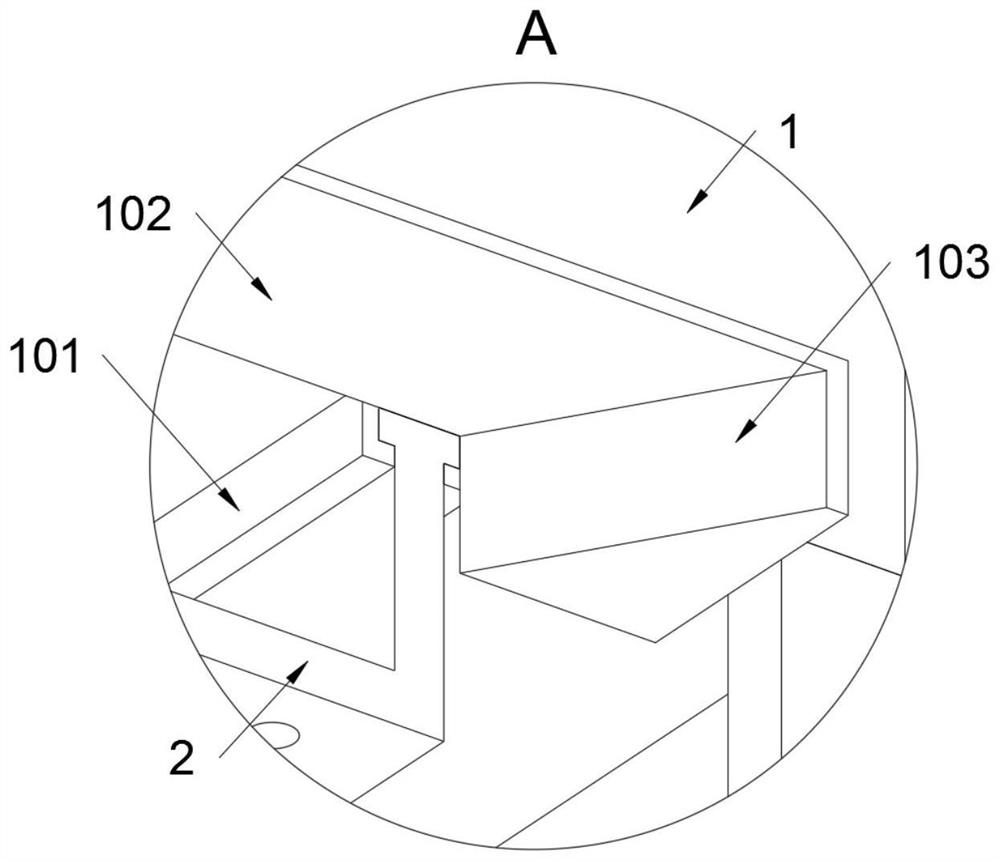

[0035] as attached figure 1 To attach Figure 8 Shown:

[0036] The present invention provides an impact-type immersion-cleaning oil pan for filter nets of heavy trucks, which includes a rectangular oil pan 1; a combustion seat 2 is inserted and fixed on the rectangular oil pan 1, and an elastic placement structure 3 is arranged in the rectangular oil pan 1 ; referenced as figure 2 with image 3 , the rectangular oil pan 1 includes a plug-in rail 101, a motor base 102, a limit block 103 and an elastic telescopic rod 104, and two plug-in rails 101 for the combustion seat 2 are welded symmetrically on the bottom end of the rectangular oil pan 1, and The combustion seat 2 is plugged into the plug-in rail 101; the front end of the rectangular oil pan 1 is welded with a motor seat 102, and the bottom end of the motor seat 102 is symmetrically welded with two limit blocks 103; the front end of the rectangular oil pan 1 is fixed by bolts An elastic telescopic rod 104 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com