Non-slipping wire drawing machine with lubricating liquid box and use method thereof

A technology of lubricating fluid and wire drawing machine, applied in the field of metal wire drawing, can solve the problems of wasting manpower and material resources, unfavorable production efficiency, slow aging speed of lubricating fluid, etc., so as to reduce the risk of wire breakage and reduce the effect of high-speed impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

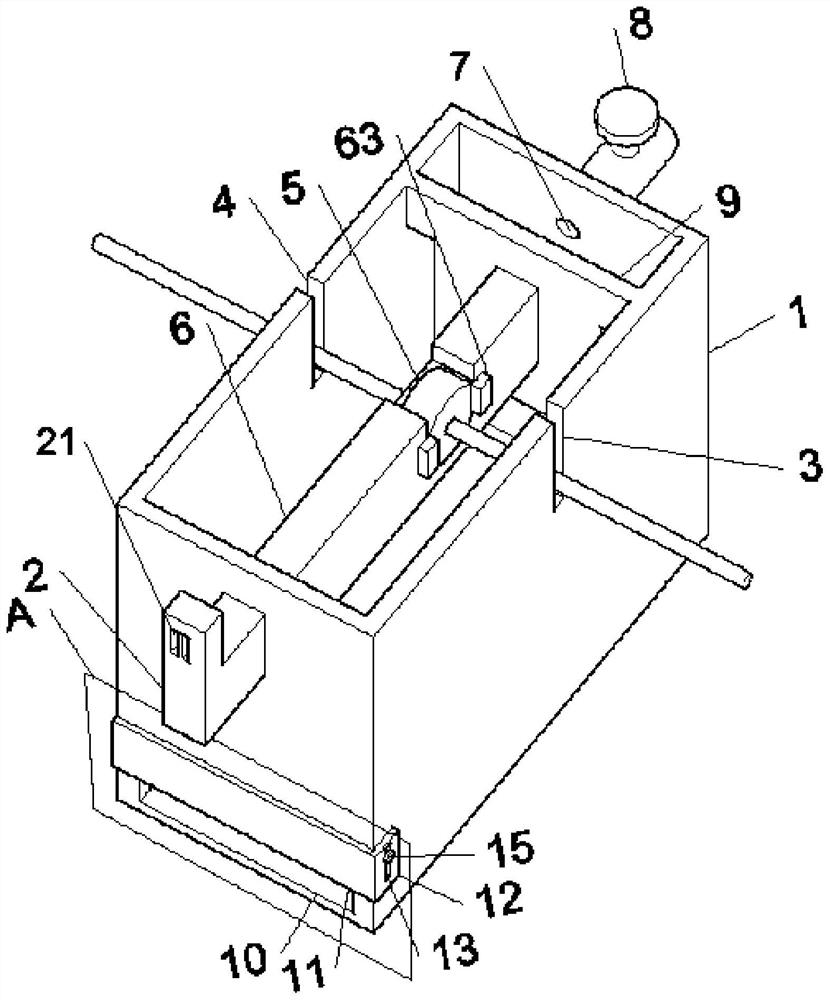

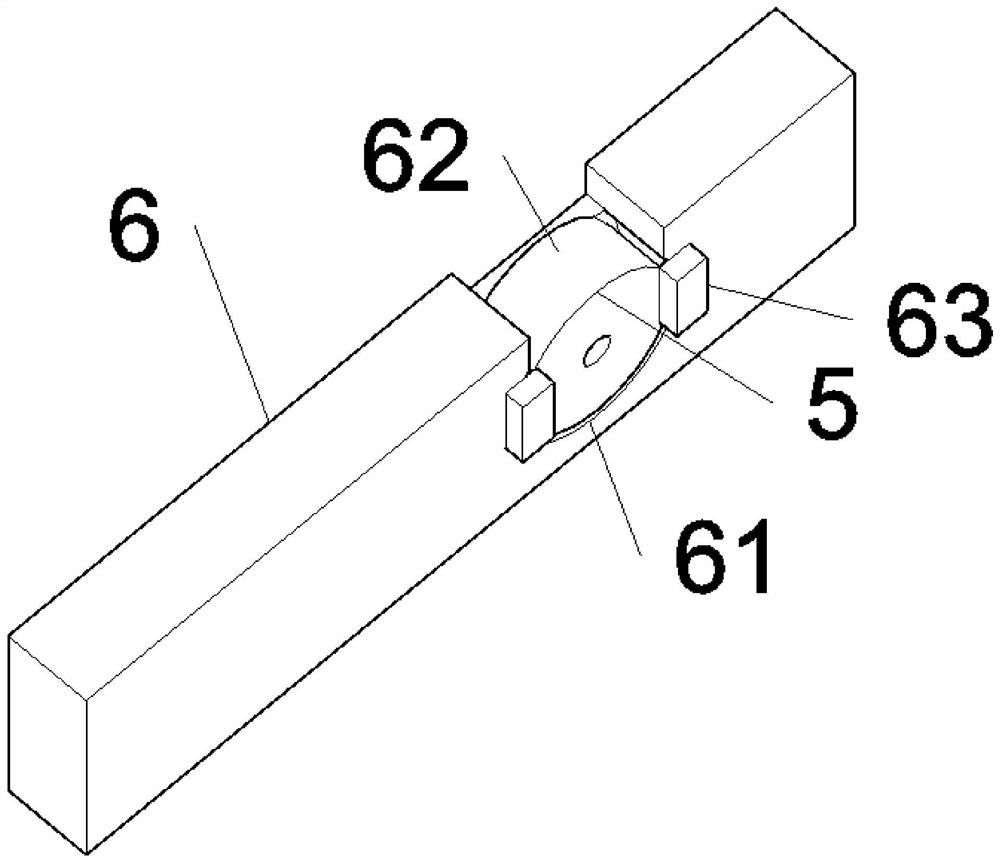

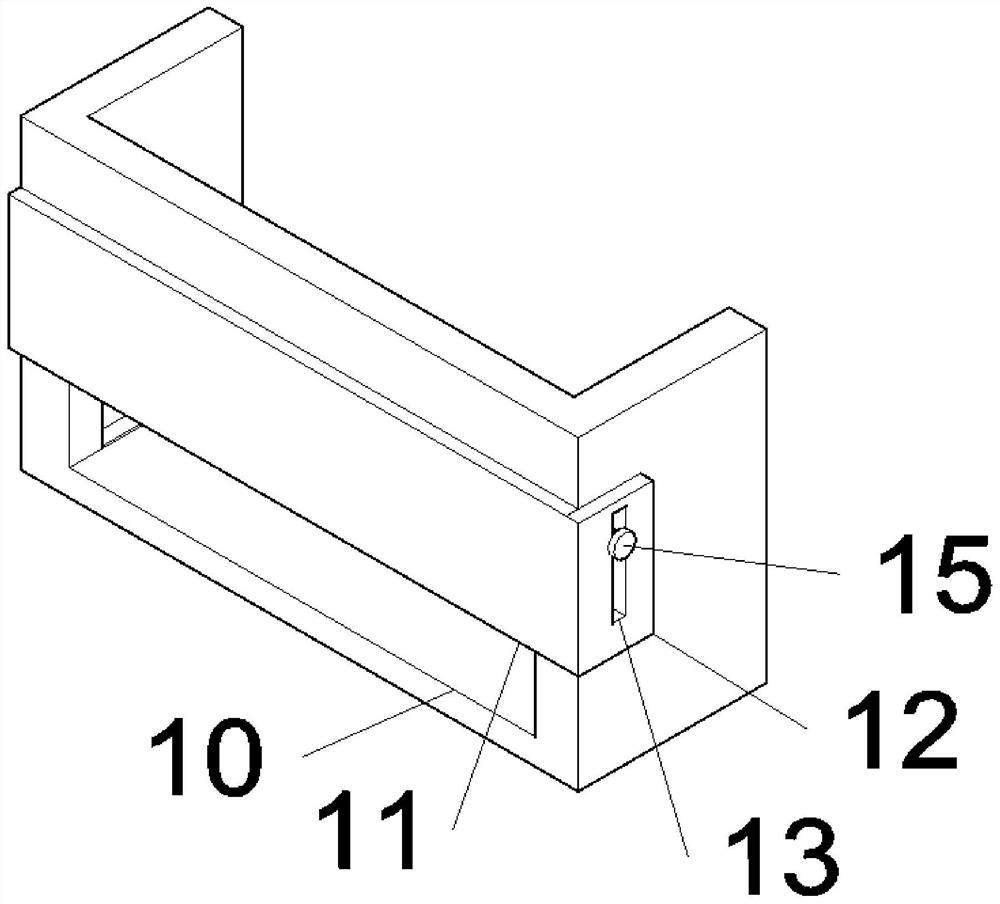

[0029] like Figure 1-Figure 4 As shown, the non-slip wire drawing machine provided with a lubricating fluid box provided in this embodiment includes a lubricating fluid box 1, a mold bracket 2 is provided on one side of the lubricating fluid box 1, and a wire inlet 3 is provided on the lubricating fluid box 1. The wire outlet 4 matched with the wire inlet 3, the lubricating box 1 is provided with a wire drawing die 5, the wire drawing hole on the wire drawing die 5 is on a straight line with the wire inlet 3 and the wire outlet 4, and the wire drawing die 5 is set in a turn card type On the bearing block 6, one end of the bearing block 6 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com