Equal-interval displacement pushing device based on continuous cutting machining

A driving device, cutting and processing technology, used in wood processing appliances, manufacturing tools, special forming/shaping machines, etc., can solve the problems of troublesome operation and low efficiency, and achieve the effect of saving cost, improving efficiency and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

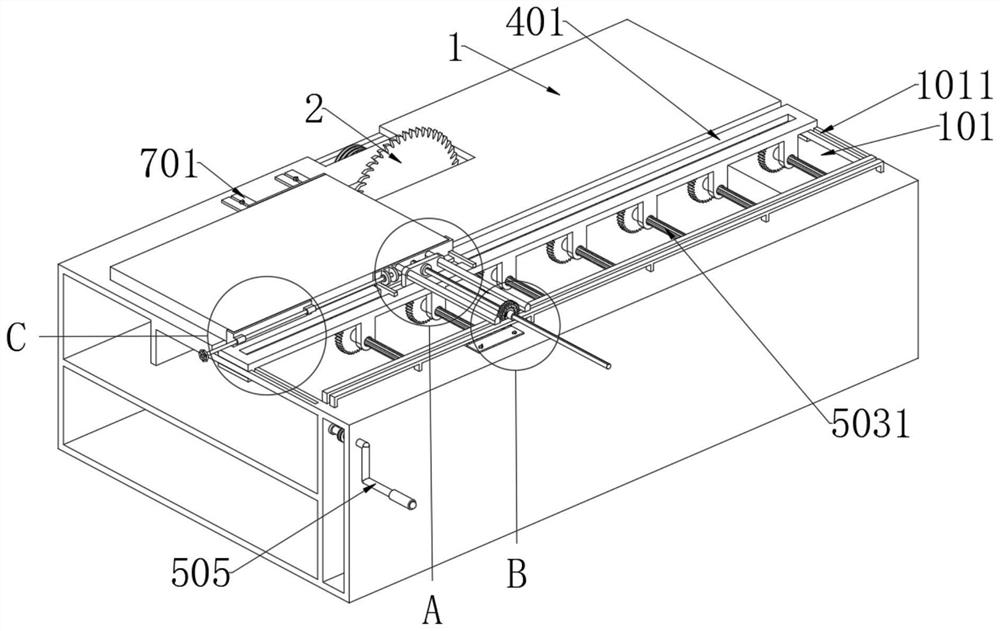

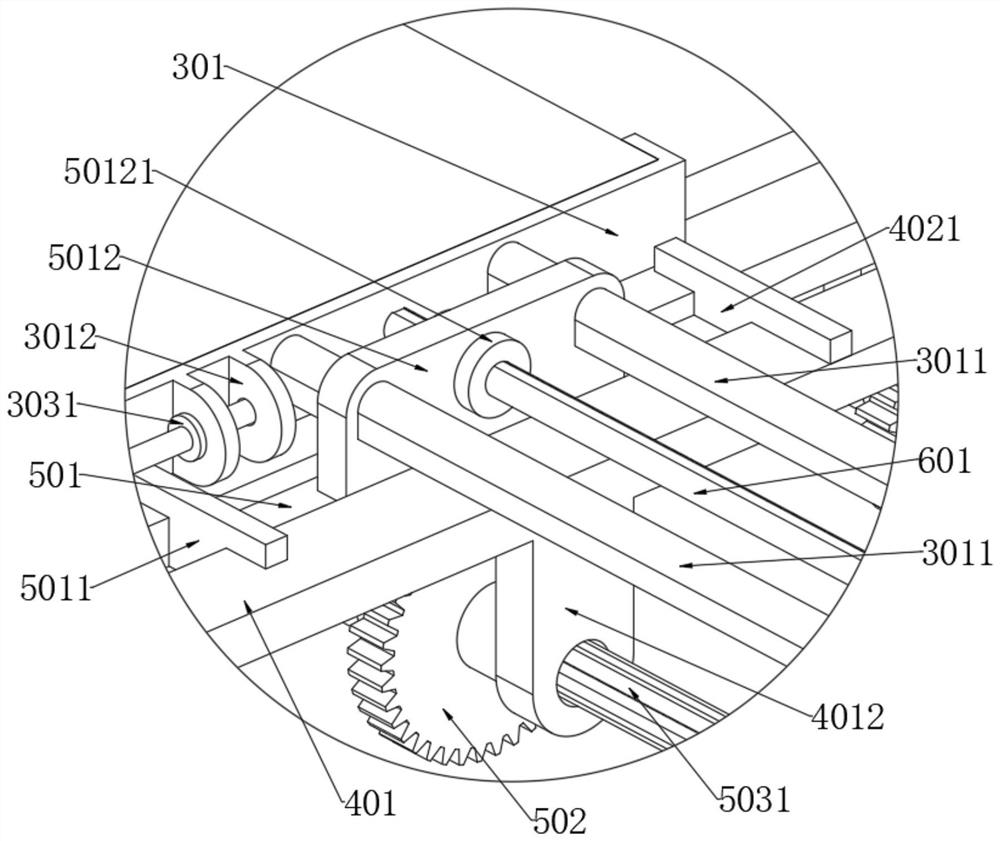

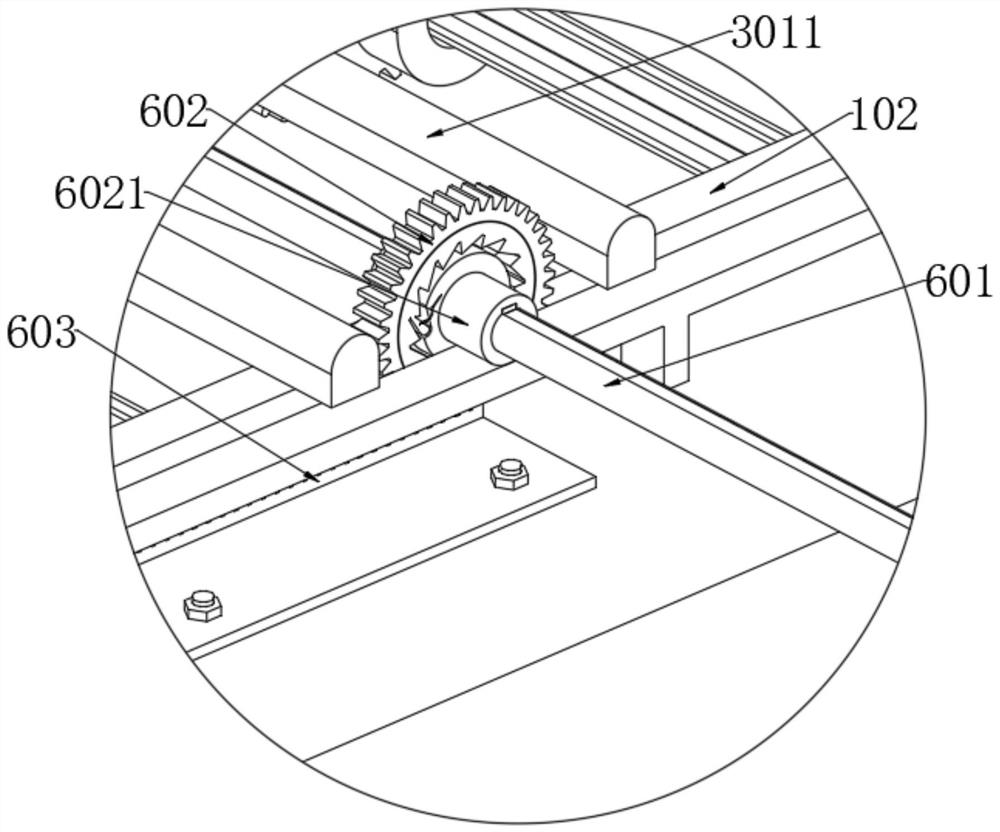

[0034] as attached figure 1 to attach Figure 9 Shown:

[0035] The invention provides an equidistant displacement pushing device based on continuous cutting processing, which includes a processing table body 1, a cutting device 2, a length adjustment clamping mechanism 3, a width adjustment mechanism 4, and a lateral pushing mechanism 6; the upper end of the processing table body 1 An adjustment port 101 is provided, and the two ends of the adjustment port 101 are provided with slide slots 1011 respectively. The cutting device 2 is fixedly installed on the processing table body 1, and the adjustment port 101 and the cutting width adjustment plate 7 are respectively arranged On both sides of the device 2, an adjustment groove plate 701 is connected to the outside of the bottom side of the cutting width adjustment plate 7, and the adjustment groove plate 701 and the processing table body 1 are adjusted and fixed by bolts, and the width adjustment mechanism 4 is slidably instal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap