Clamping structure of cargo supporting device

A clamping structure and supporter technology, which is applied in the direction of freight vehicles, motor vehicles, load fixing, etc., can solve the problems of poor movement stability of the chuck, and achieve the goal of improving market competitiveness, good operation feel, and easy favor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

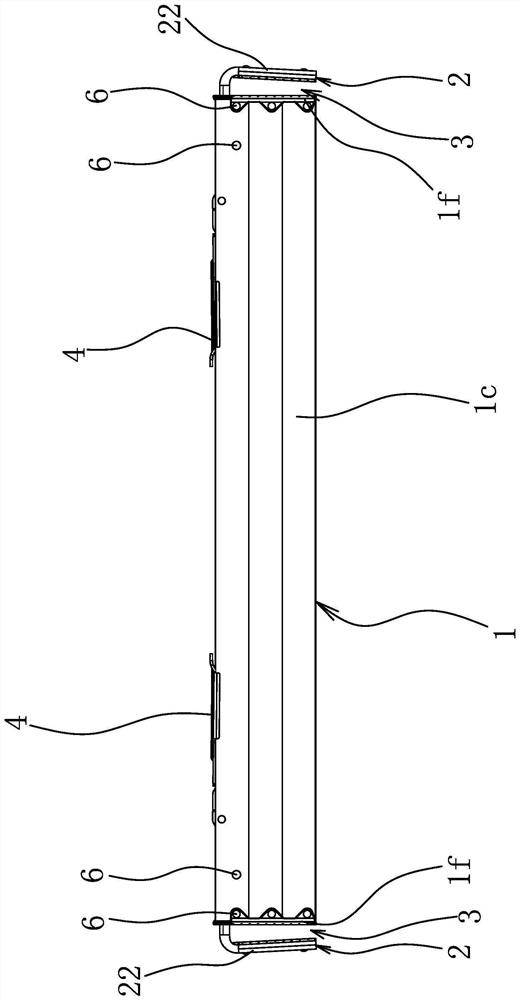

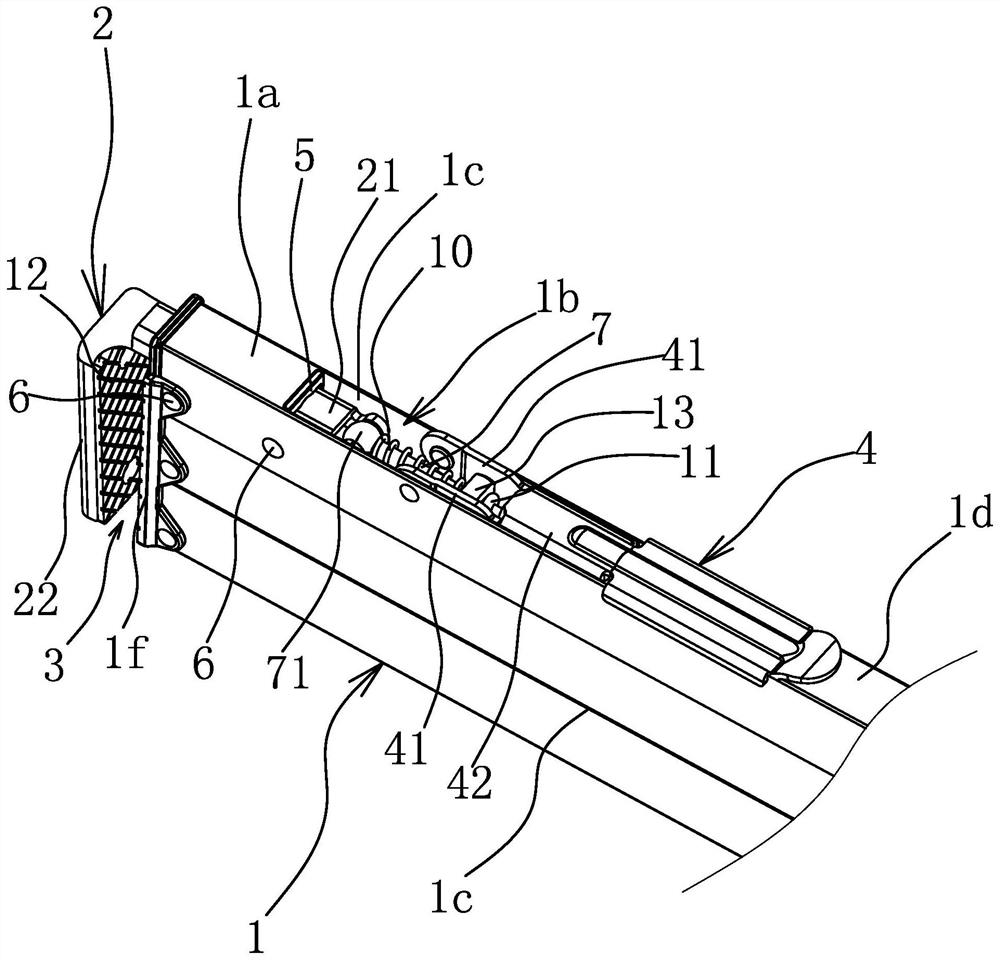

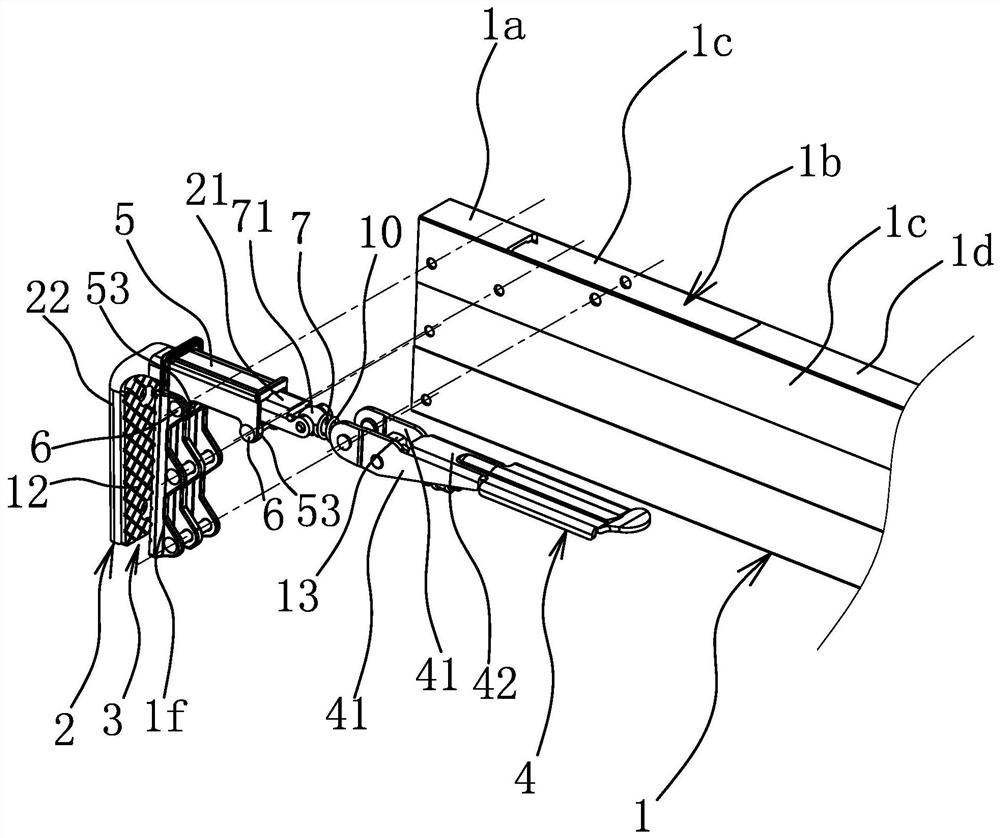

[0046] Such as figure 1 and figure 2 As shown, the cargo support includes a beam 1, and the two ends of the beam 1 are respectively provided with clamping structures with the same structure. The clamping structure includes a chuck 2 arranged at the end of the beam 1. The chuck 2 has a guide part 21 and a clamping part 22. The guide part 21 is strip-shaped and arranged along the axial direction of the beam 1. The beam 1 is a hollow structure and clamps The guide portion 21 of the head 2 extends into the beam 1 , and the clamping portion 22 is connected to one end of the beam 1 protruding outward from the beam 1 and is bent downward relative to the guide portion 21 . In order to increase the friction during the clamping process to ensure the stability of the clamping, a rubber pad 1f is fixedly connected to the end face of the beam 1, and a rubber pad 2 opposite to the rubber pad 1f is also fixed on the clamping part 22. 12. At this time, a jaw 3 is formed between the clampin...

Embodiment 2

[0052] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that there are differences in the guiding structure: as Figure 9 and Figure 10As shown, the beam 1 is provided with a top plate 1a located on the upper side of the guide part 21, and the guide structure includes two supports 6 fixed at the end of the beam 1, and the two supports 6 are all located below the guide part 21. The two supports 6 are set at the same height and have intervals between them. Each support 6 is rotatably provided with a roller sleeve 8. The bottom surface of the guide 21 is supported on the roller 8. The top surface of the guide 21 is connected to the top plate The bottom surface of the body 1a forms a sliding fit. The top surface of the guide part 21 forms a sliding fit with the bottom surface of the top plate body 1a, and there may be a slight gap between the top surface of the guide part 21 and the bottom surface of the top plate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com