Jacking buffer device capable of automatically regulating

An automatic adjustment and cushioning device technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of different compression distances of shock-absorbing materials and inaccurate positioning of manipulators, so as to reduce the hidden danger of bumping, reduce the distance, and reduce the moving path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

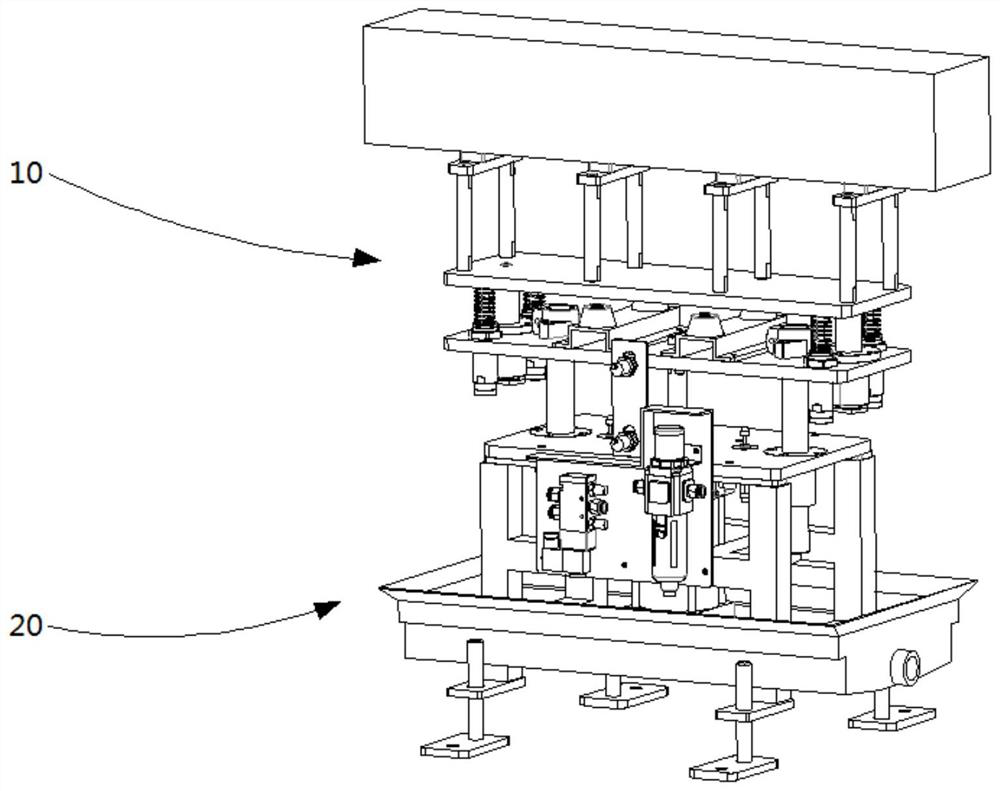

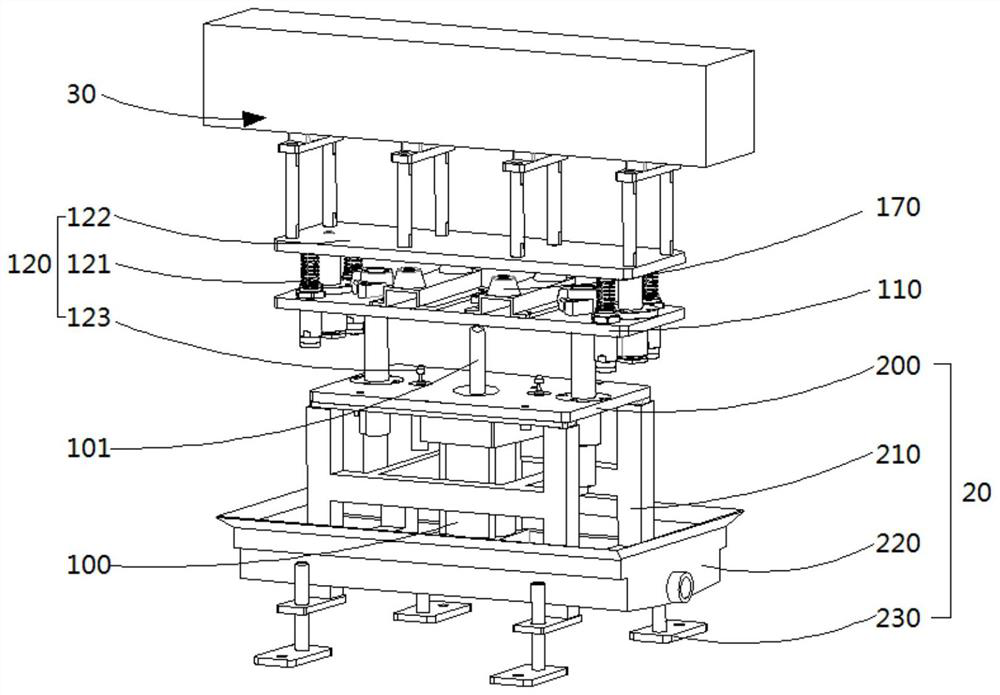

[0033] see figure 1 and figure 2 , The automatic adjustment jacking buffer device 10 is installed on the frame 20 . The frame includes a base plate 200, a support 210, a water tray 220, and several supports 230. The base plate is installed on the top surface of the support 210 as an installation reference for the automatic adjustment of the lifting buffer device; the supports 230 are installed at the bottom of the support and arranged at intervals for The support adjustment bracket; the water receiving tray 220 is located between the base plate and the support, and is fixed around the support, and is used to centrally receive the liquid carried by the workpiece. The automatic jacking buffer device 10 includes a driving member 100 , a jacking plate 110 , an adjustment assembly 120 , and a control assembly; the adjustment assembly includes a damping buffer 121 , a floating plate 122 , and a hydraulic buffer 123 . In this embodiment, the driving part is replaced by a cylinder,...

Embodiment 2

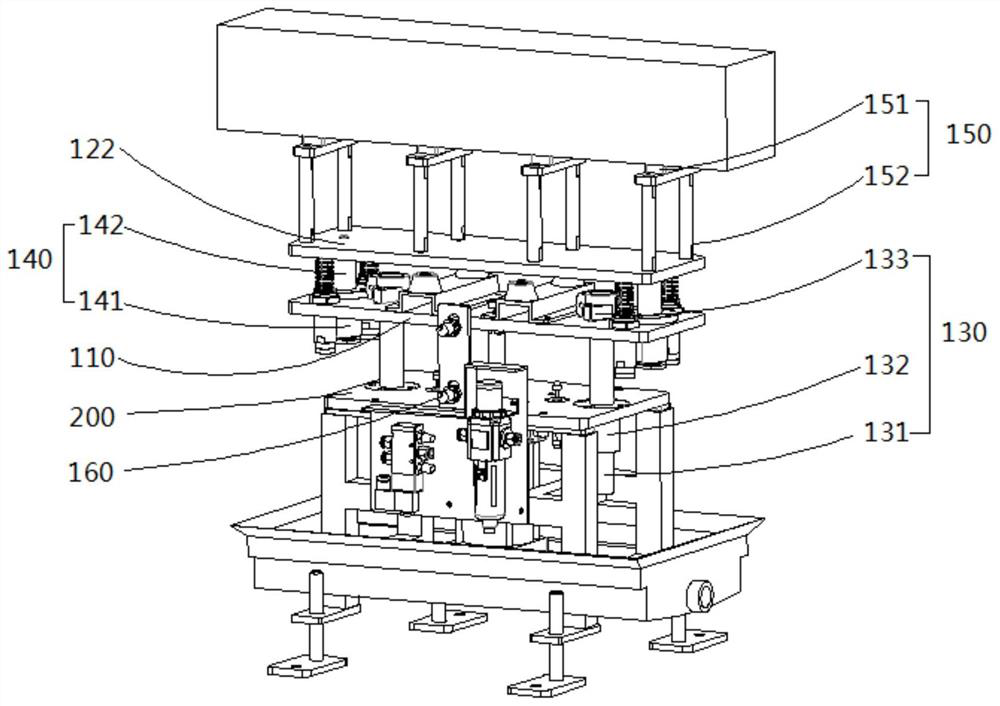

[0036] Refer to attached image 3 As shown, in order to ensure the stable vertical operation of the floating plate and avoid the tilting of the workpiece after being placed, the present invention also provides a second guide assembly 140 . One end of the second guide assembly is connected to the lifting plate 110 , and the other end is connected to the floating plate 122 . Specifically, the second guide assembly includes a bearing 141 and a T-shaped shaft 142 . The bearing passes through the lifting plate and is fixed on the lifting plate, the small end of the T-shaped shaft is embedded in the bearing and the protruding bearing is arranged, and the protruding end is screwed with the floating plate.

[0037] It should be noted that at least two groups of the first guide assembly and the second guide assembly are respectively provided. In order to ensure the jacking force of the cylinder and the balance of the jacking plate, floating plate, etc., it is best to set an even number...

Embodiment 3

[0039] Refer again to the attached image 3 As shown, on the basis of the first embodiment, a shock absorbing mechanism 150 is arranged on the floating plate. The shock absorbing mechanism includes a contour column 151 and a buffer bar 152, the contour column is fixed on the floating plate, the buffer bar is installed on the contour column, and the workpiece is placed on the buffer bar. The buffer strip can be a nylon strip or a rubber strip, and any elastic material with shock absorption and cushioning can be used, which is not specifically limited in this embodiment. In order to further ensure that the workpiece is placed on the buffer bar without contact scratches and the workpiece is placed stably, the contact surface between the buffer bar and the workpiece is set as a discontinuous surface. As shown in the figure, there are 8 intervals of contour columns and 4 buffer bars, which can be flexibly designed according to specific working conditions in practical applications....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com