Ocean current power generation auxiliary force taking structure

An ocean current and power generation unit technology, applied in the field of auxiliary power take-off structures, can solve problems such as low conversion rate, and achieve the effects of improving conversion rate, providing efficacy and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

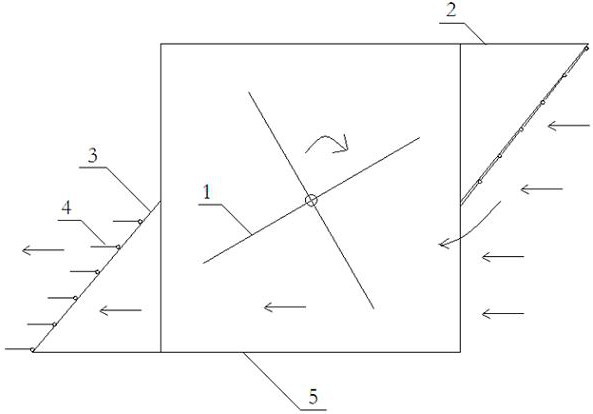

[0014] Such as figure 1 As shown, an auxiliary power take-off structure for ocean current power generation includes at least one auxiliary power take-off frame 2, the auxiliary power take-off frame 2 is installed on the facing surface of the power generation unit frame 5, and is located outside the power generation unit frame 5; The power frame 2 has at least one inclined plane frame 3, one end of which is connected to the power generation unit frame 5 on the upstream side, and forms an acute angle with the power generation unit frame 5 on the upstream side that it blocks. In order to solve the problem of power take-off at low flow rates, the water is introduced into the positive work side of the rotating frame in the frame of the power generation unit through the inclined plane frame on the water facing surface, and the side doing negative work on the return journey of the rotating frame is blocked by the inclined plane frame, effectively Block the impact of incoming water on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com