Elastic claw type cotton picker

A spring-tooth and spring-tooth technology, which is applied in the fields of picking machines, agricultural machinery and implements, and applications, can solve the problems of high impurity content and incomplete seed cotton shape of the unified harvesting cotton picker, and increase the impurity content. , not easy to wear, strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

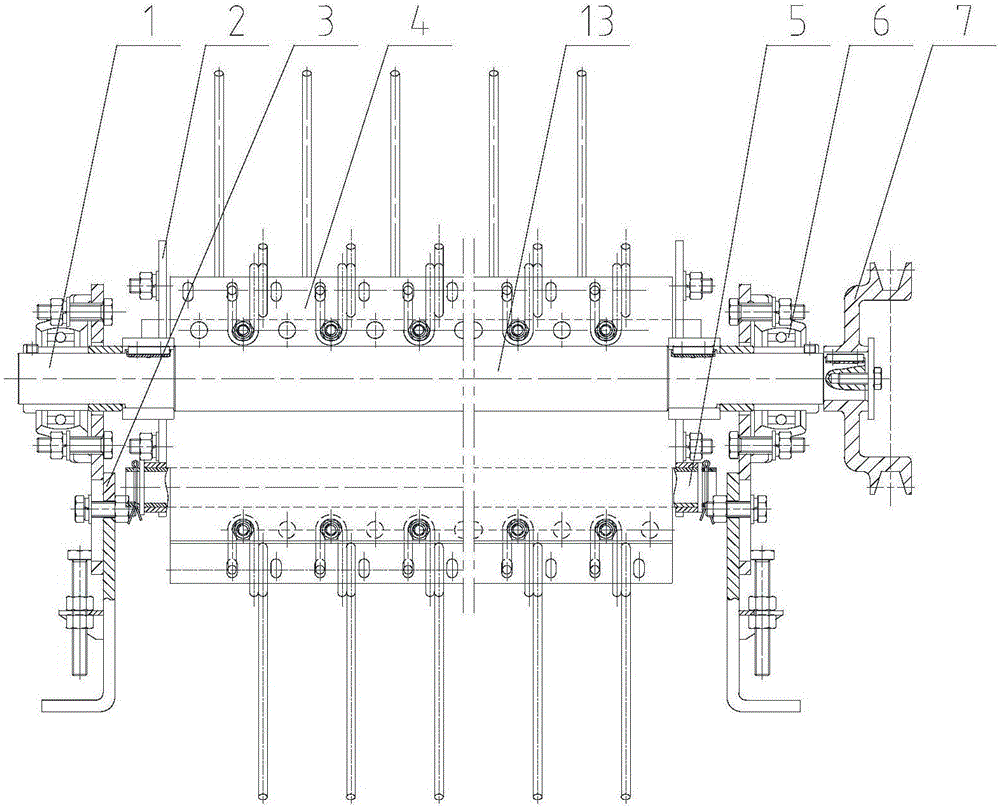

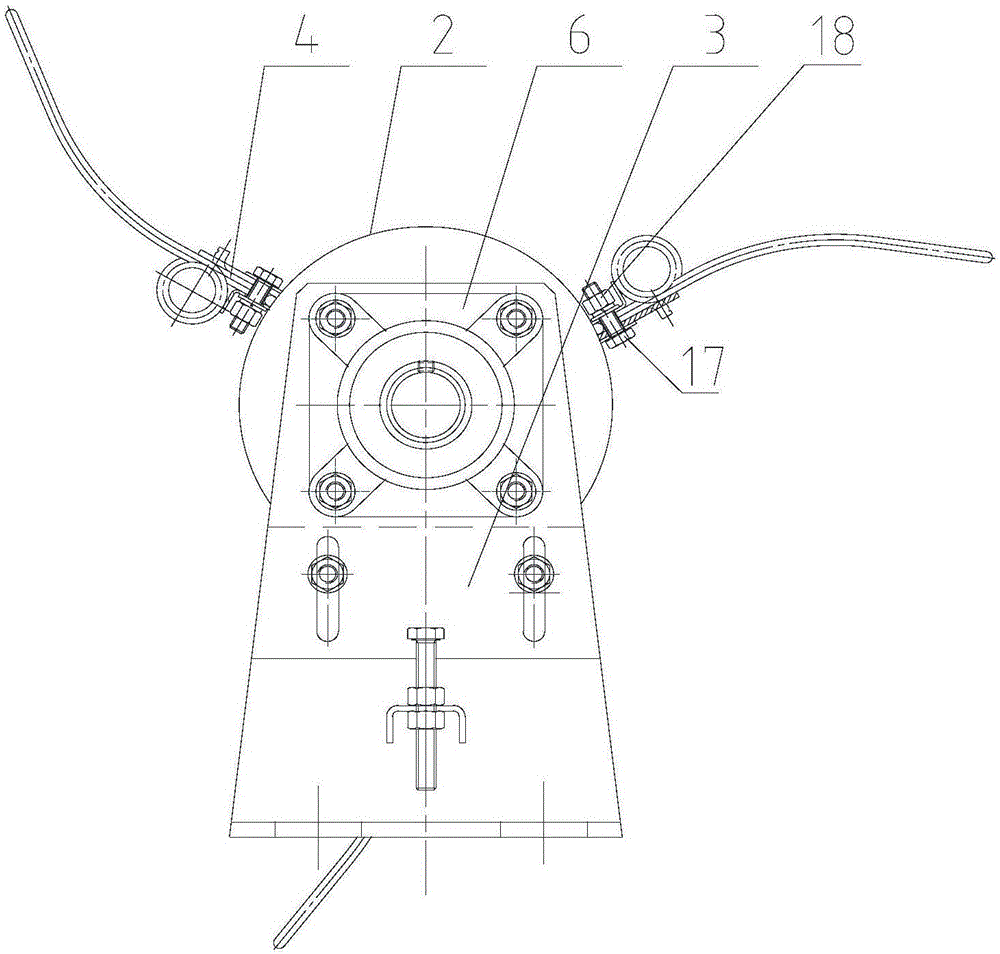

[0025] The elastic teeth type cotton picking device of the present embodiment, as Figure 1-Figure 7 As shown, it includes a picking roller 13 and a driving mechanism 7 for driving the picking roller 13 to rotate. In this embodiment, the driving mechanism 7 adopts a pulley transmission mechanism.

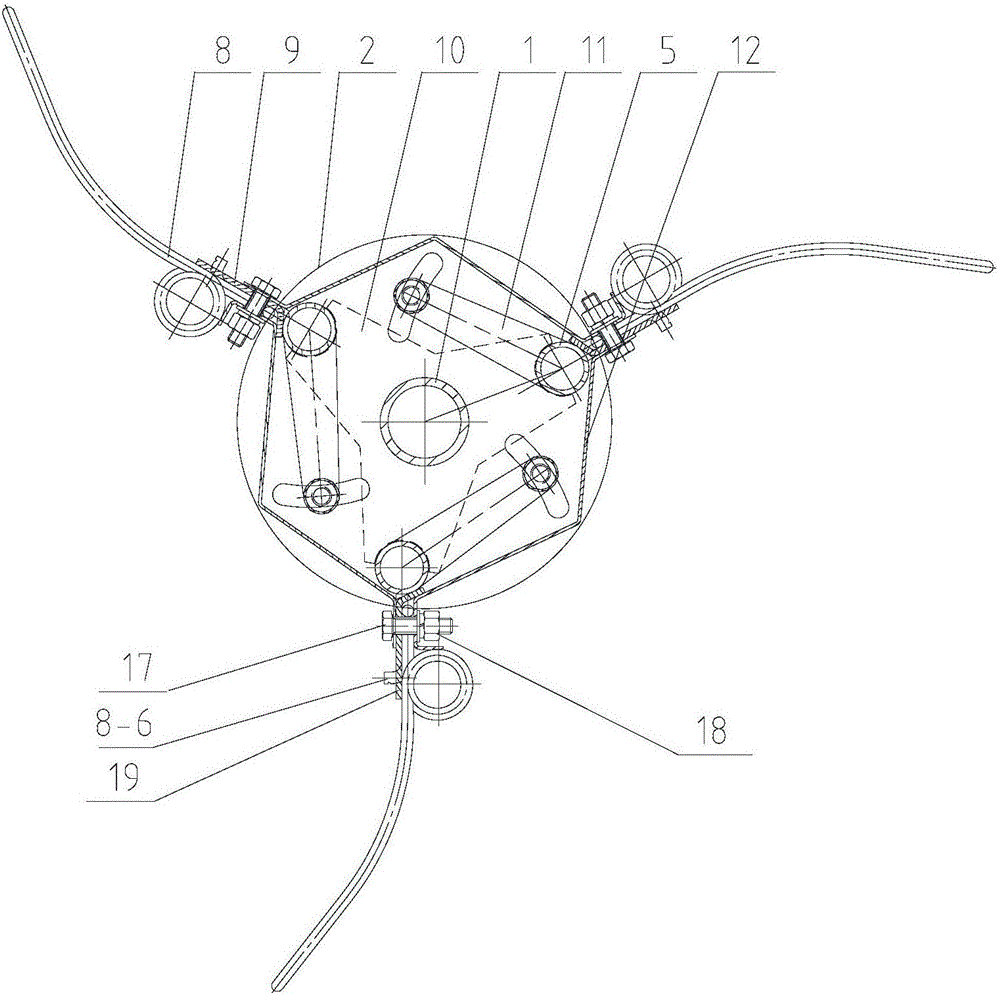

[0026] Such as figure 1 and figure 2 As shown, in the present embodiment, the picking roller 13 includes a rotating shaft 1 installed on the support base 3 through a bearing seat 6 and a plurality of elastic toothed rods 4 arranged at intervals on the outer periphery of the rotating shaft 1. The elastic toothed rods 4 and the rotating shaft 1 Parallel, several spring teeth 8 are installed on the length direction of the spring tooth bar 4, and the spacing between two adjacent spring teeth 8 on the spring tooth bar 4 is 20-35mm.

[0027] Such as Figure 6 and Figure 7 As shown, in this embodiment, the spring teeth 8 are made of spring steel wires, and extending outward from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com