An asynchronous ignition method for dual spark plugs based on optimized lean burn

A dual-spark plug, lean-burn technology, applied in spark ignition controllers, engine ignition, automatic control, etc., can solve the problems of gasoline engine efficiency and power reduction, gasoline engine knocking, and increased nitrogen oxide emissions. Achieve the effect of reducing HC and CO, perfecting the lean combustion process and reducing harmful emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

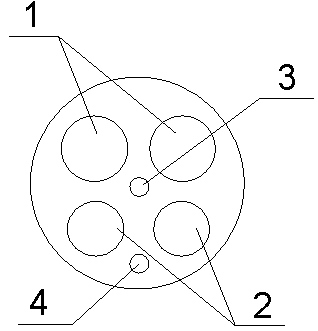

[0021] Example: see figure 1 , a dual spark plug asynchronous ignition method based on optimized lean burn, including a gasoline engine body. The gasoline engine body includes at least one group of cylinder heads, which have two intake valves 1, two exhaust valves 2 and a piston, and a main spark plug 3 is arranged on the top of the cylinder head, and the main spark plug 3 is located between two The central position of the intake valve 1 and the two exhaust valves 2; a secondary spark plug 4 is also arranged between the two exhaust valves 2.

[0022] Described asynchronous ignition method comprises the steps:

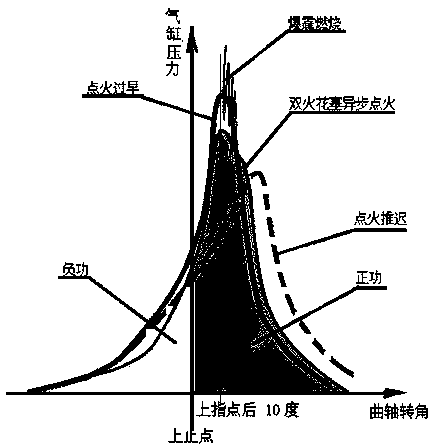

[0023] 1) Before the piston reaches the top dead center, the ignition timing of the gasoline engine with the ideal mixture ratio 1 is delayed by 3~7° (crank angle), and the main spark plug 3 is controlled to ignite first. Specifically (compared with the ignition timing of a gasoline engine with an ideal mixture ratio of 1, so the speed factor is not considered):

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com