A method for energy-saving of high-low partition stratified lean-burn engine

A lean-burn, partitioned and stratified technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of increasing pumping loss, increasing fuel consumption, and large pumping loss, etc., to improve thermal efficiency and improve air conditioning. The effect of reducing fuel ratio and pumping loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

[0038] An energy-saving method for a stratified lean combustion engine with high and low partitions, at least including the following steps:

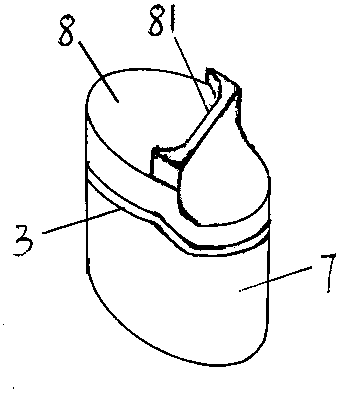

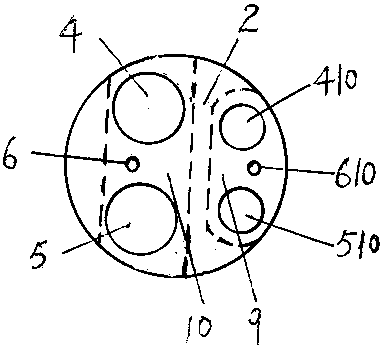

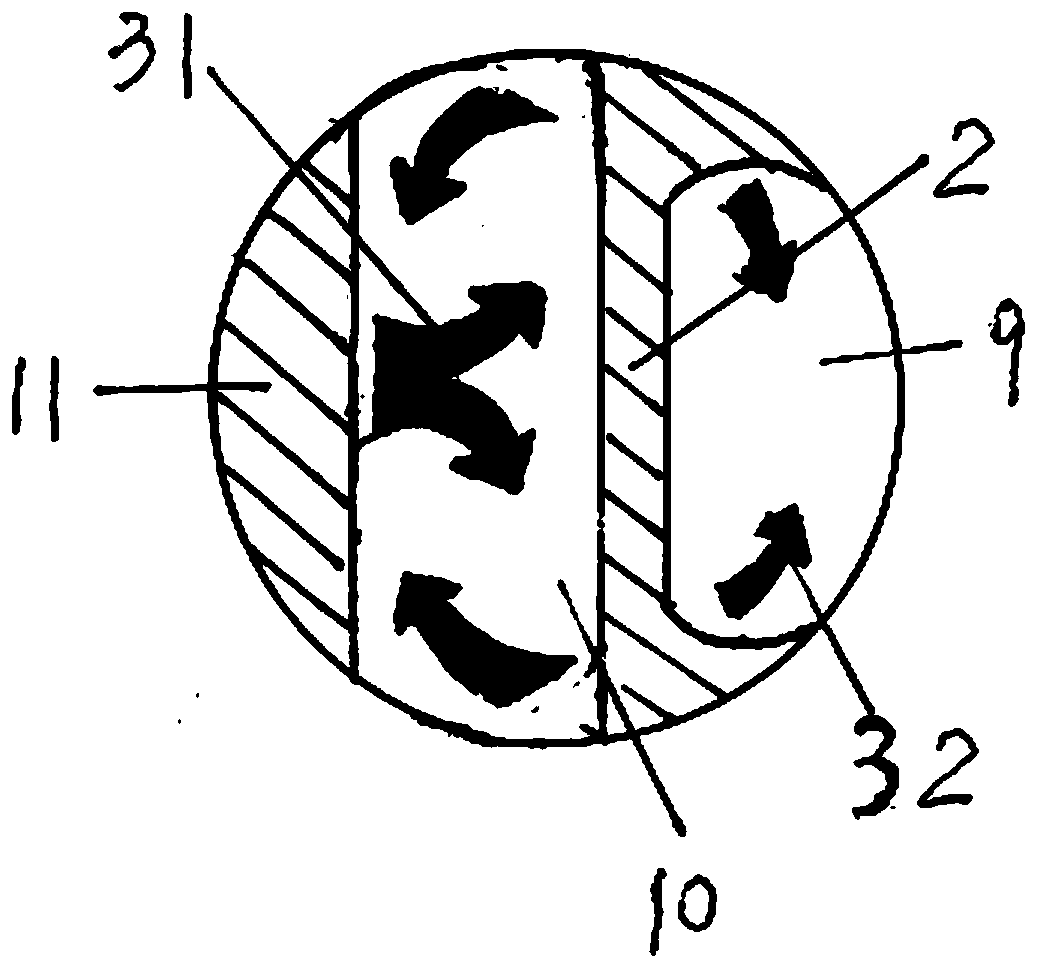

[0039] In the first step, the cylinder is divided into at least two combustion zones, and each combustion zone has a large combustion zone and a small combustion zone of different sizes, and the large combustion zone and the small combustion zone are set in a stepped shape, so as to realize the top of the cylinder Partition combustion;

[0040] In the second step, a spark plug, an exhaust pipe and an intake pipe are connected on the cylinder head corresponding to the cylinder of each combustion chamber, and a cylinder pipe divider plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com