Clean production equipment and process for whole pulping and papermaking process

A clean production, pulping and papermaking technology, applied in textile and papermaking, fiber raw material processing and other directions, can solve the problems of insufficient pulp cleanliness, troublesome operation, pulp pollution, etc., and achieve the effect of increasing environmental protection, increasing compactness and compact setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

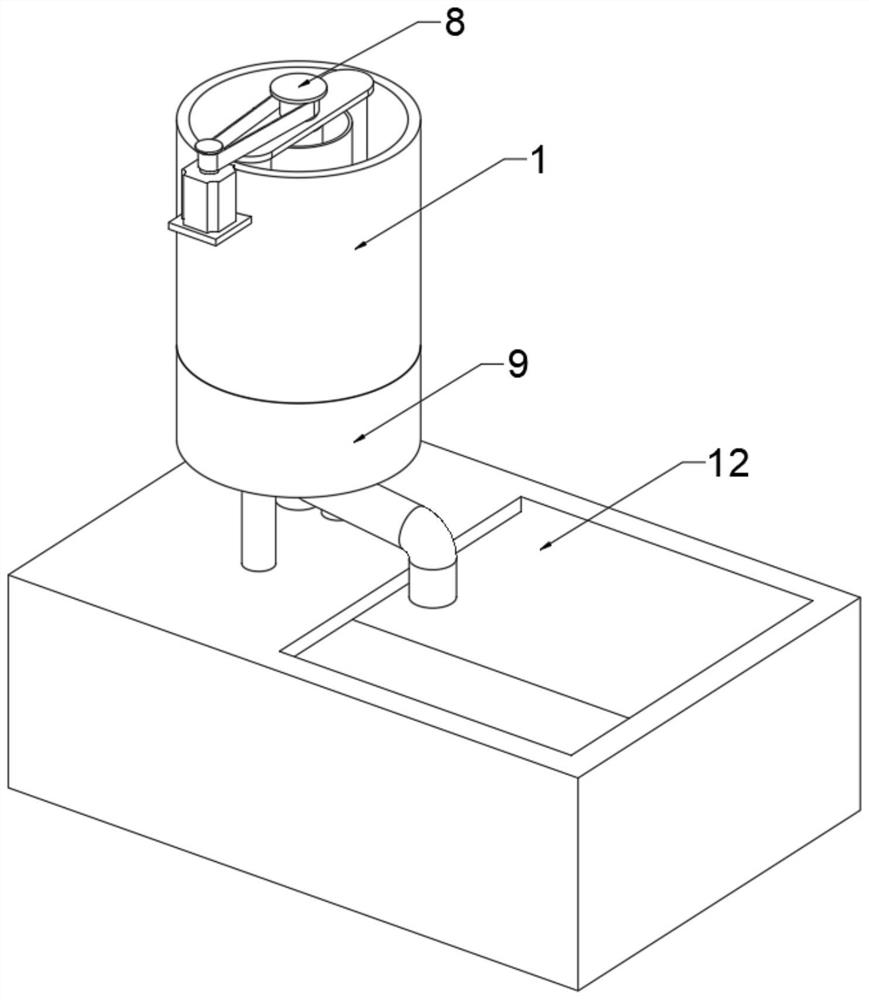

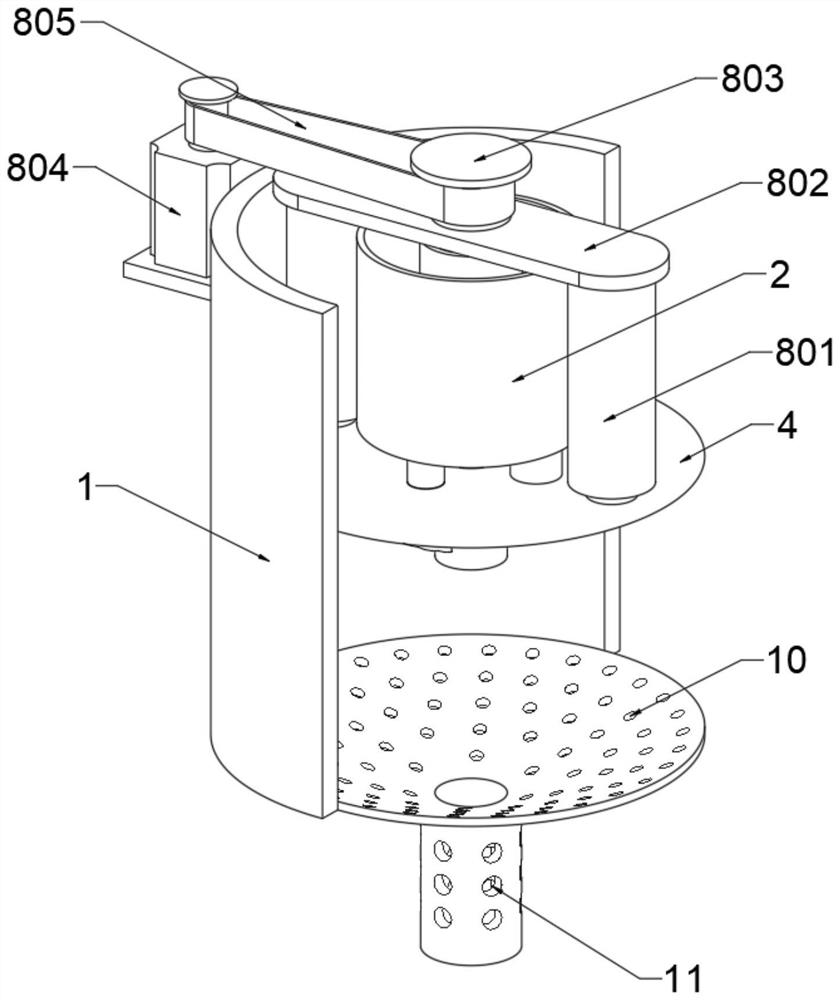

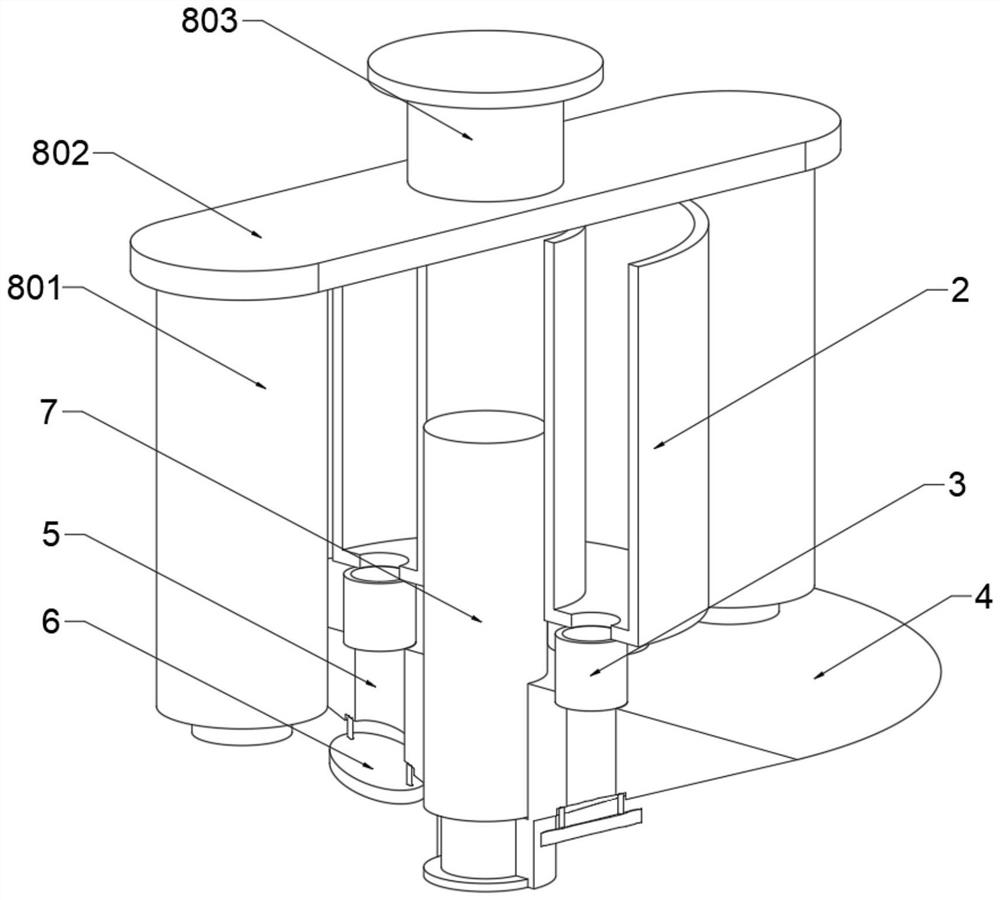

[0039] refer to Figure 1-Figure 7 As shown, a clean production equipment for the whole process of pulping and papermaking includes a reaction kettle 1, a pressure block 4 is arranged inside the reaction kettle 1, and an ingredient cup 2 is arranged on the top of the pressure block 4, and the interior of the ingredient cup 2 is provided with a The stirring mechanism 7, the rotation mechanism 8 is provided on the outer side of the ingredient cup 2, the bottom of the reaction kettle 1 is provided with a filter plate 10, and the bottom of the filter plate 10 is provided with a separation mechanism 9, and the bottom of the separation mechanism 9 is provided with a wire separating device 12 .

[0040] like image 3 As shown, the bottom of the ingredient cup 2 is symmetrically provided with a liquid conduit 3, the inside of the pressing block 4 is symmetrically provided with a guiding groove 5, and the guiding groove 5 is matched with the liquid guiding tube 3, and the bottom of th...

Embodiment 2

[0046] A clean production process for the whole process of pulping and papermaking of the above embodiment, comprising the following steps:

[0047] S1: First, take out the pulping raw materials and the decomposing fungi. The ratio of the raw materials to the decomposing fungi is 1:1. The decomposing fungi include HYH7 black rot bacteria, FYR6 soft rot bacteria and ZYB5 anaerobic white rot bacteria, and the ratio is 1:1: 1;

[0048] S2: place the pulping raw materials and the decomposing fungi in the interior of the batching cup 2 at the same time, and soften the pulping raw materials with lignin and pectin fructose by the decomposing fungi, and then transport the softened pulping to the interior of the reactor 1;

[0049] S3: Start the stirring mechanism 7 and the rotating mechanism 8 to stir to fully decompose until the decomposing fungi completely decompose the pulping raw materials;

[0050] S4: Stop the stirring mechanism 7, restore it, and then cooperate with the separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com