Cylinder type tooth plate coal crushing gangue machine

A cylinder type and tooth plate technology is applied in the field of the cylinder type tooth plate coal crusher and gangue discharger to achieve the effects of eliminating gangue with less coal, small external dimensions and less investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

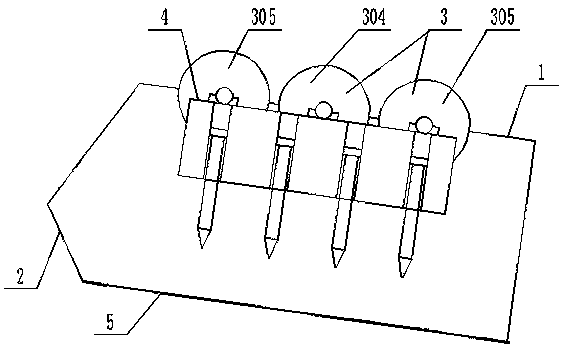

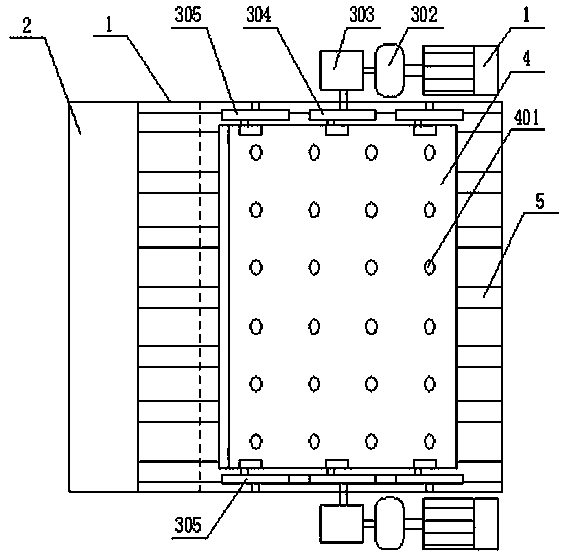

[0019] The cylinder type tooth plate coal breaking and gangue discharge machine includes a box body 1, the left end of the box body 1 is provided with an inclined feeding chute 2, the bottom of the box body 1 is fixed with a sieve plate 5, and the sieve plate 5 is connected to the bottom edge of the feeding chute 2 connect. The upper part of the sieve plate 5 is provided with a cylinder tooth plate 4 and a driving device 3 which can allow the cylinder tooth plate 4 to perform circular motion. Such as figure 2 As shown, a motor is provided on both sides of the cylinder tooth plate 4 to drive the driving eccentric 304 after passing through the hydraulic coupling 302 and the reducer 303 . The two active eccentric wheels 304 drive the four passive eccentric wheels 305, so that the cylinder tooth plate 4 keeps parallel and performs circular motion as a whole, and the radius of the circular motion is 400 mm. Said cylinder gear plate 4 is evenly distributed with piston cylinders 4...

Embodiment 2

[0022] Such as figure 1 As shown, on the basis of Example 1, the angle between the sieve plate 5 and the horizontal plane is set to 20°, and the angle between the feeding chute 2 and the horizontal plane is 50°. When the chute 2 enters the box body 1, it is convenient to feed the material, which reduces the resistance when the piston rod picks up the material, and at the same time, the material will not automatically slide down from the sieve plate 5 . Simultaneously, the mechanical driving mode of the present invention can be changed into hydraulic pressure or air pressure. According to the amount of material and the flow rate of the material, the piston cylinder 401 on the cylinder tooth plate 4 can also be adjusted to six horizontal rows, six vertical rows, and the spacing between the horizontal and vertical rows. The present invention can adjust the structure of the present invention according to different factors in the actual operation process, such as the difference of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com