Car engine with ignitron structre

A technology of automobile engine and pilot tube, which is applied in combustion engine, internal combustion piston engine, machine/engine, etc., can solve problems such as unsatisfactory, and achieve the effect of improving utilization rate and reducing pollutant discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1

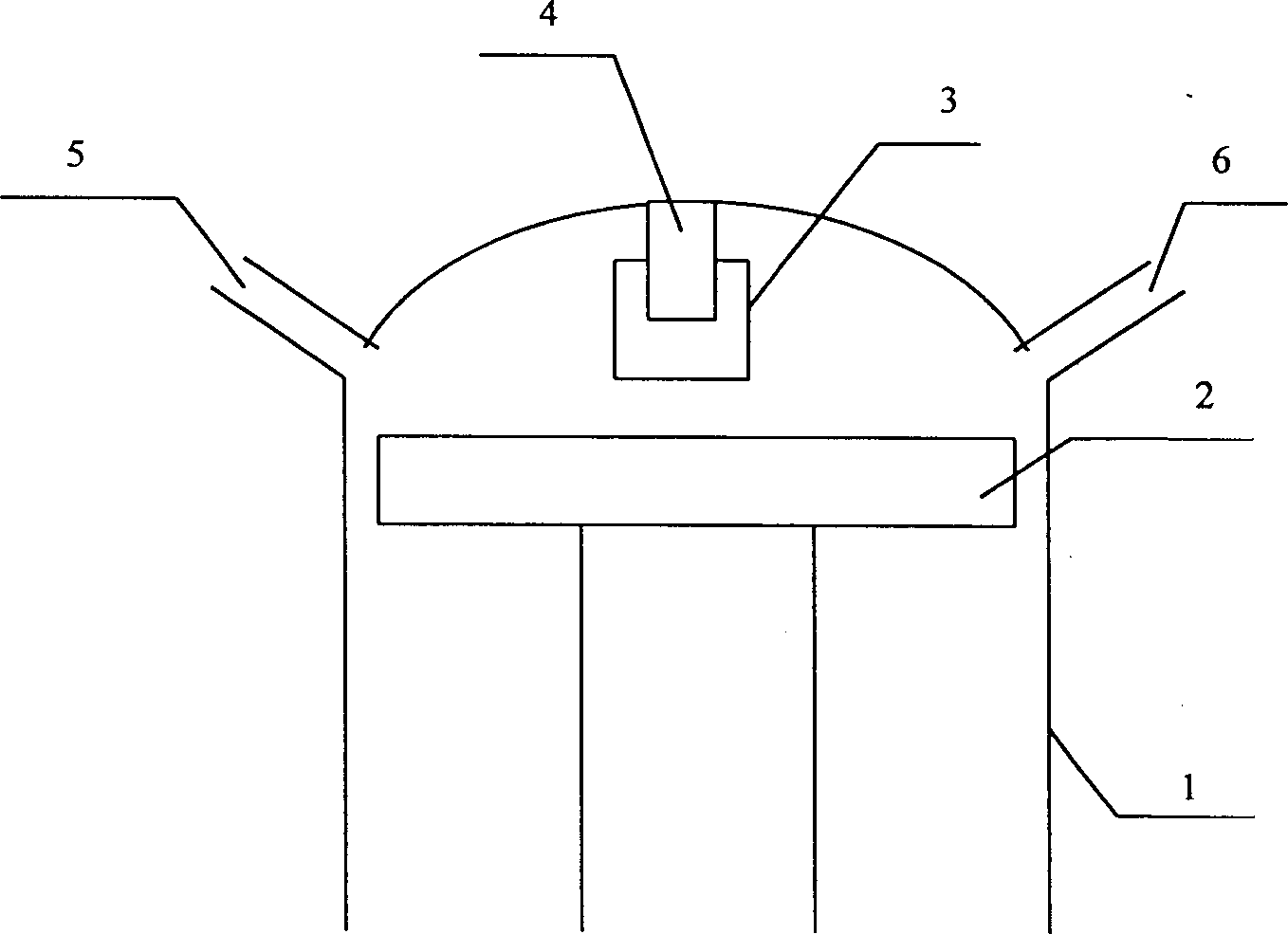

[0020] Make an automobile engine with an ignition tube structure as shown in Figure (1): a ignition tube structure is fixed in the engine block 1 with the engine piston 2, and an ignition tube structure is installed in an ignition tube 3 A spark plug 4 is formed, and the spark plug 4 is fixed in the upper cover of the engine block 1; an air inlet 5 and an air outlet 6 are symmetrically opened on the upper cover of the engine block 1 .

Embodiment (2

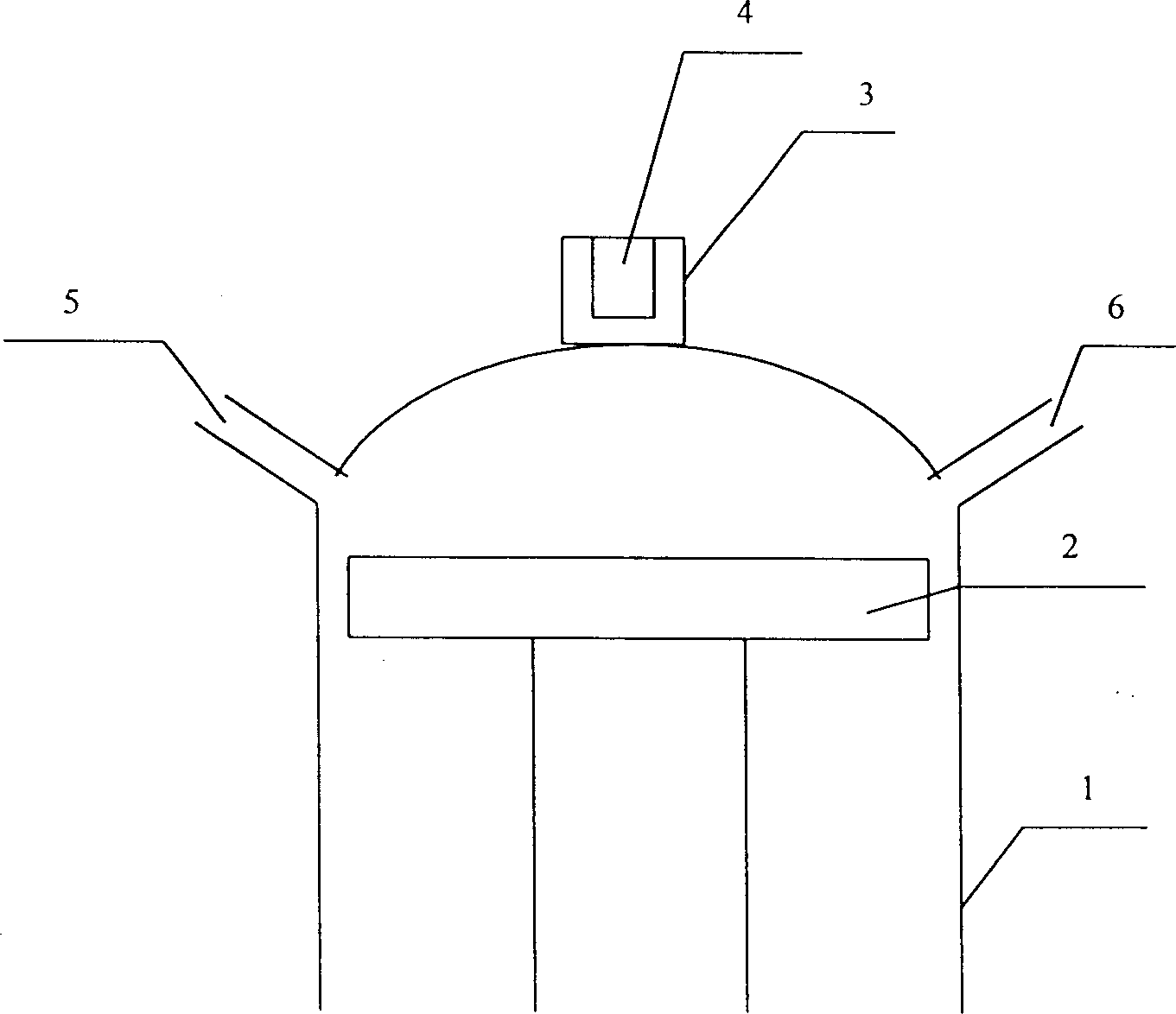

[0022] Make an automobile engine with an ignition tube structure as shown in Figure (2): an ignition tube structure is installed on the outer top of the engine block 1 loam cake with the engine piston 2, and this ignition tube structure consists of an ignition tube 3 A spark plug 4 is installed inside and the ignition tube 3 is fixed on the engine block 1 loam cake; an air inlet 5 and an air outlet 6 are symmetrically opened on the engine block 1 loam cake.

Embodiment (3

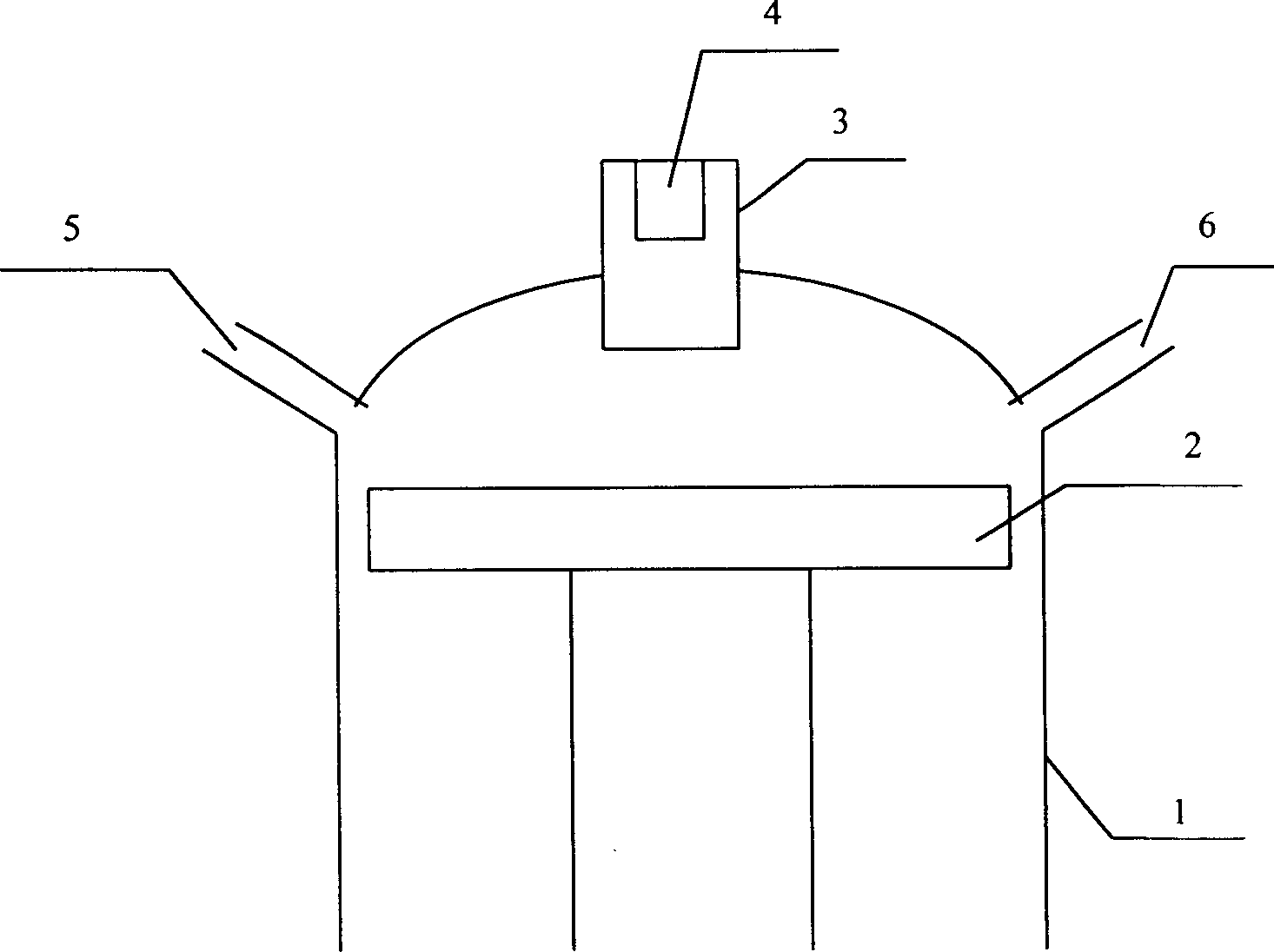

[0024] Make an automobile engine with an ignition tube structure as shown in Figure (3): an ignition tube structure is installed on the engine block 1 loam cake with the engine piston 2, and the ignition tube 3 parts stretch into the cylinder and are fixed on In the middle of the upper cover, a spark plug 4 is installed inside the ignition tube 3; an air inlet 5 and an air outlet 6 are symmetrically opened on the engine block 1 upper cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com