A method for self-adaptive flow control of a range hood

A technology of self-adaptive control and range hood, which is applied in the directions of oil fume removal, application, heating method, etc., can solve the problems of large amount of calculation, large fluctuation in the test of flow velocity sensor and pressure sensor, and small flow of range hood, etc., and achieves control accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

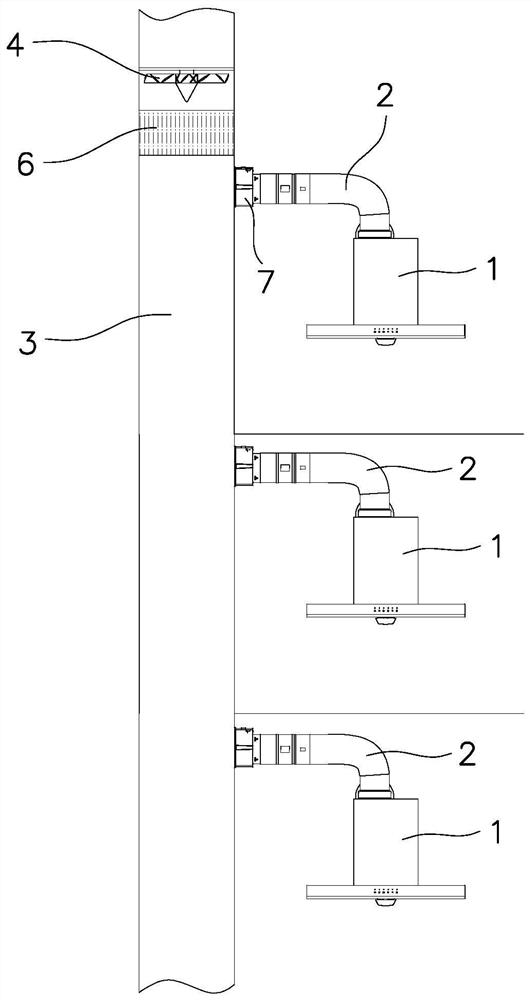

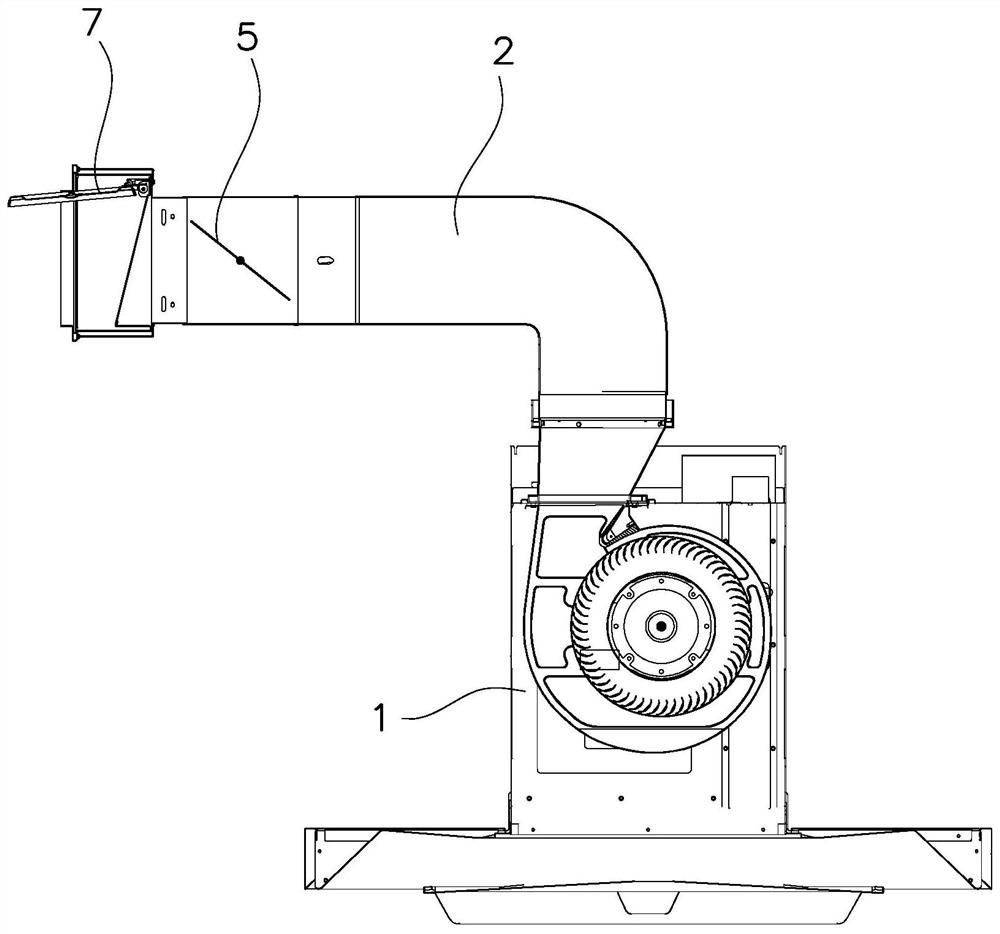

[0035] Such as figure 1 with figure 2 As shown, the flue system of a high-rise building in this embodiment includes range hoods 1 installed on different floors, and the air outlets of each range hood 1 are communicated with the public flue 3 through respective smoke pipes 2, and the smoke pipes 2 is equipped with a fire damper 7, and the outlet of the public flue 3 is equipped with an outdoor host 4, and the public flue 3 can be a straight flue (such as figure 1 shown) or stepped flue (such as Image 6 shown). A check valve plate 5 is installed in each smoke pipe 2 . An outdoor host 4 is installed at the outlet of the public flue 3, and a purification device 6 is installed at the front end of the outdoor host.

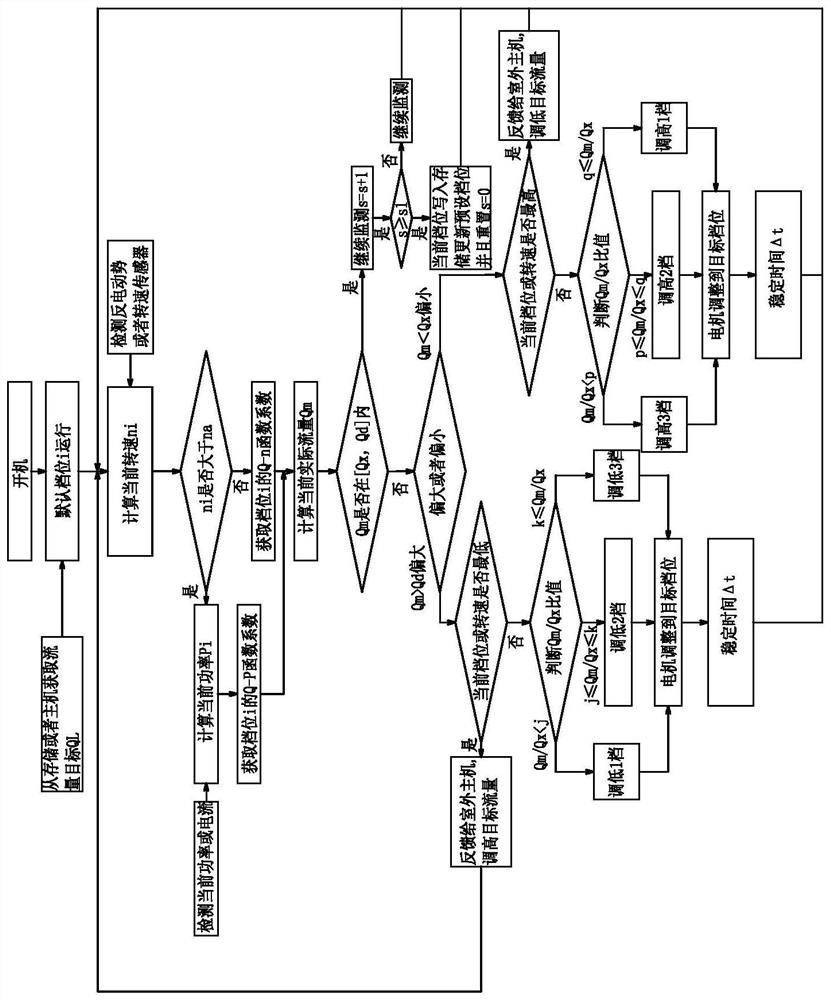

[0036] The self-adaptive control method for the range hood flow rate in this embodiment is a networked operation mode. First, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com