Full-automatic ice separating structure capable of quantitatively discharging ices

An ice structure, fully automatic technology, applied in the field of fully automatic ice separation structure, can solve the problems of drink splashing, occupying a large space, affecting the normal packaging of drinks, etc., to achieve the effect of reducing the possibility and occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

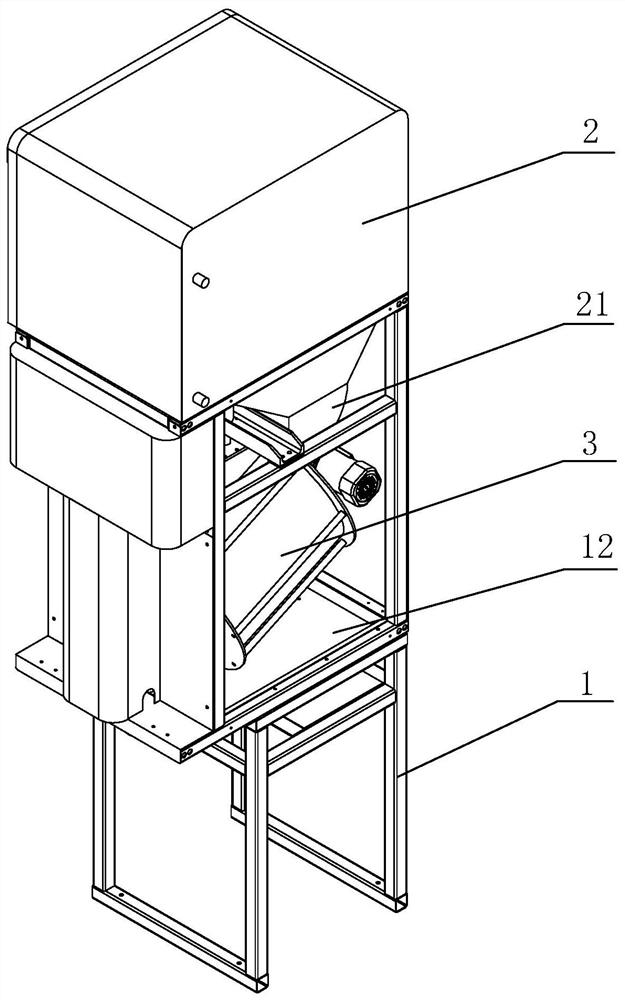

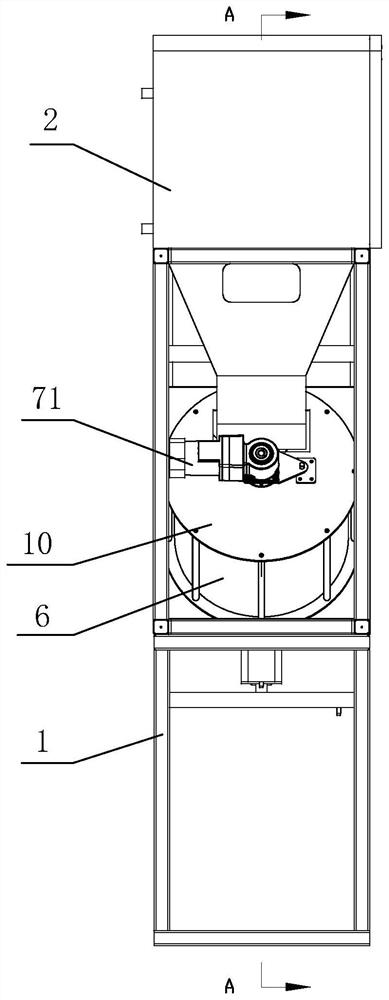

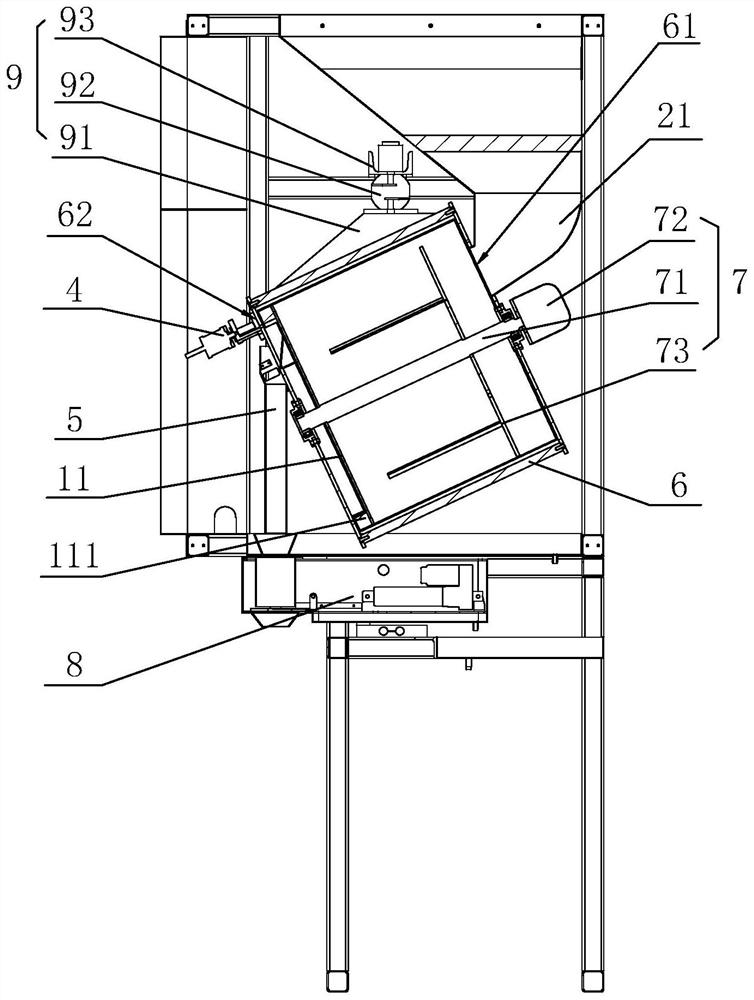

[0024] like figure 1 As shown in the figure, a fully automatic ice separation structure that can quantitatively produce ice is provided on the ice machine. The ice machine includes a rack 1, an ice making device 2 and an ice cube exporting structure 5. The ice making device 2 and the ice cube exporting structure 5 are arranged on the rack 1 in order from top to bottom. The ice separating device includes an ice ejecting drum 3 and an ice ejecting control structure 4. The ice making device 2 is communicated with the ice ejecting drum 3 through a sealed lower hopper 21, and the ice ejects The drum 3 is communicated with the ice extraction structure 5 , and the ice ejection control structure 4 is installed at the ice ejection position of the ice ejection drum 3 to control whether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com