Continuous automatic production equipment for spherical balls

A production equipment and meatball technology, which is applied in the field of meatball blank production equipment and continuous automatic production equipment for spherical meatballs. It can solve the problems of poor control of the degree of frying of meatballs, a large drop in oil temperature, and increased sticking of meatballs, etc., to achieve appearance quality. Stability, reduced labor intensity, and the effect of reducing the adhesion of meatballs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

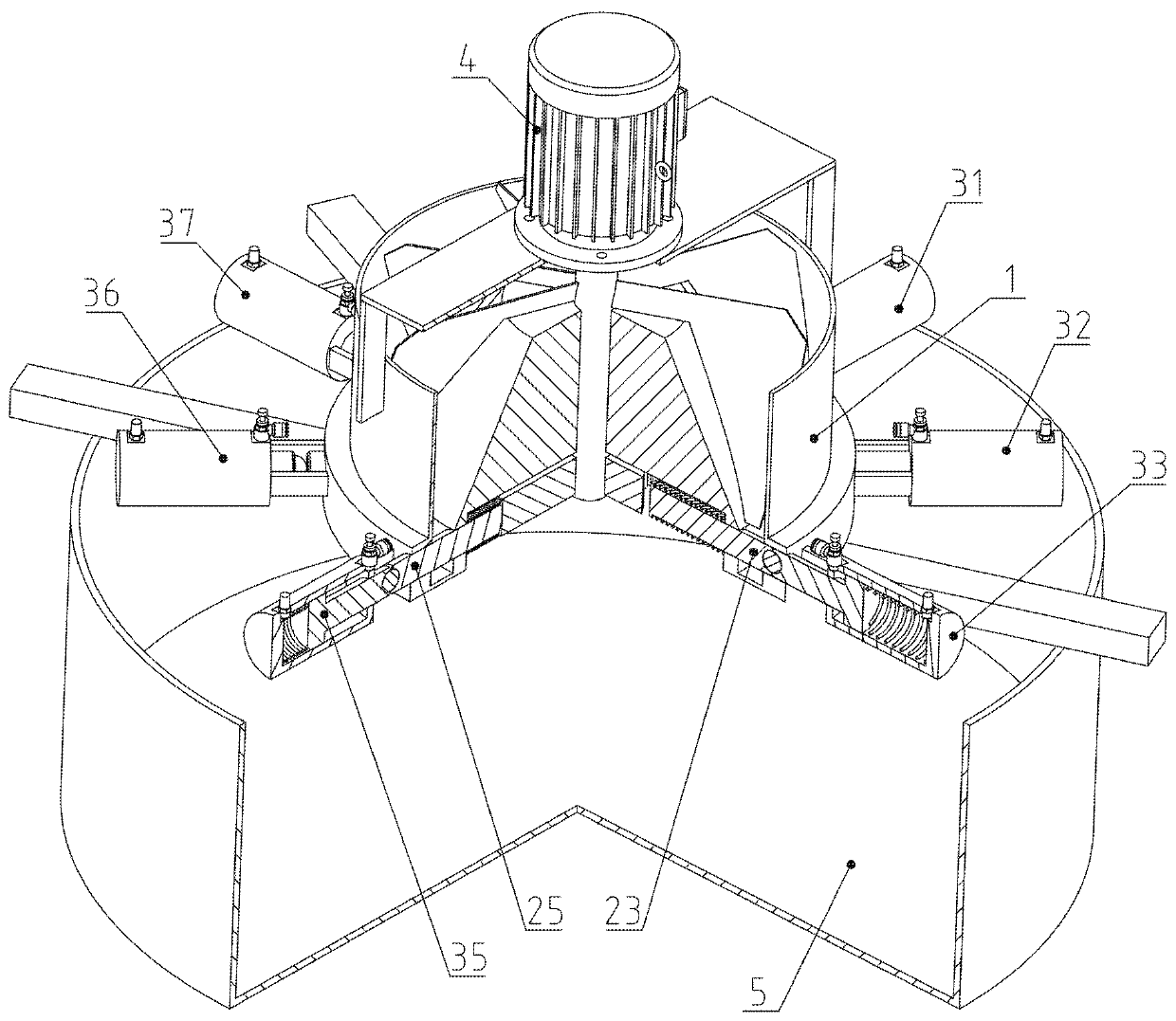

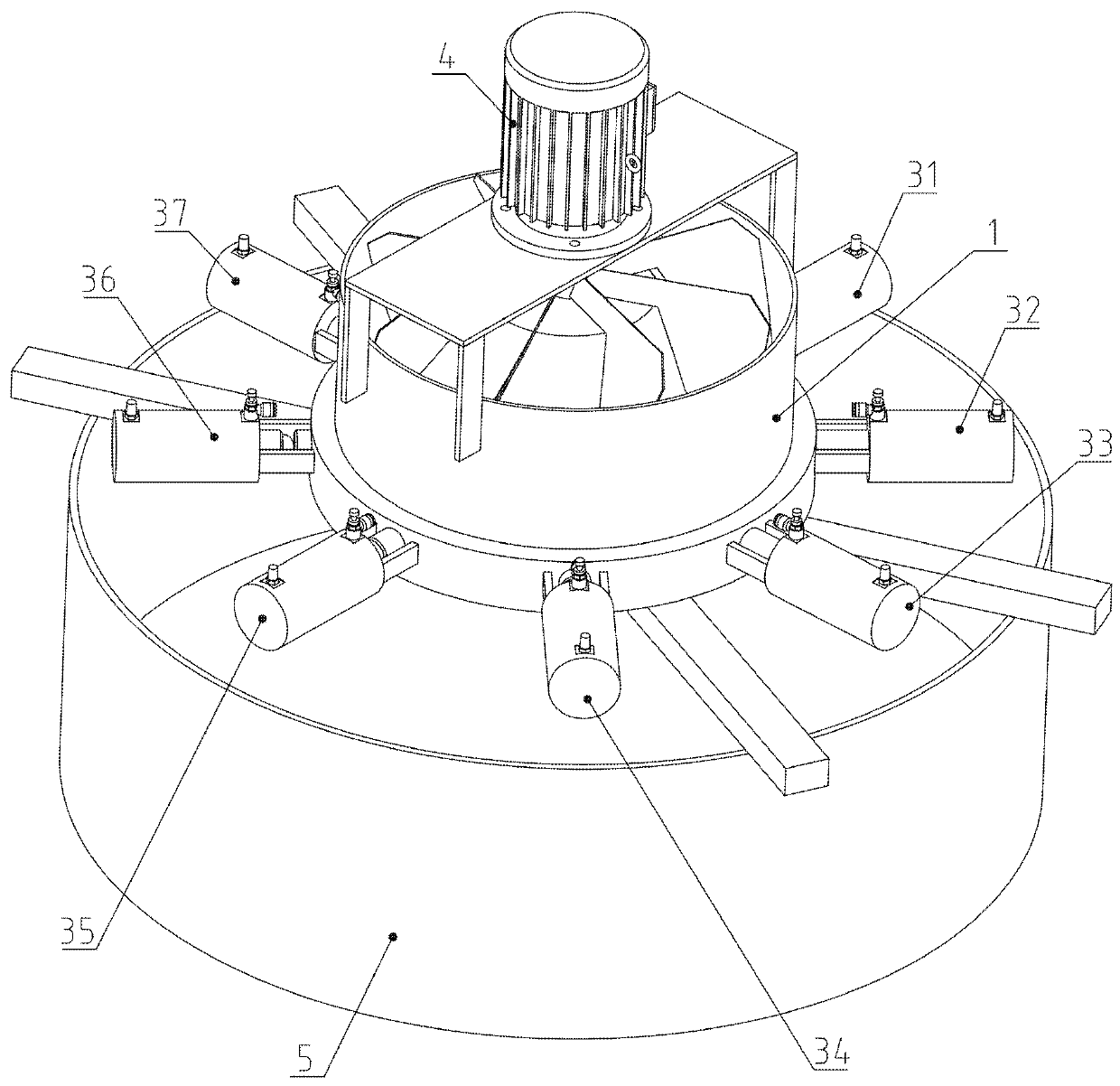

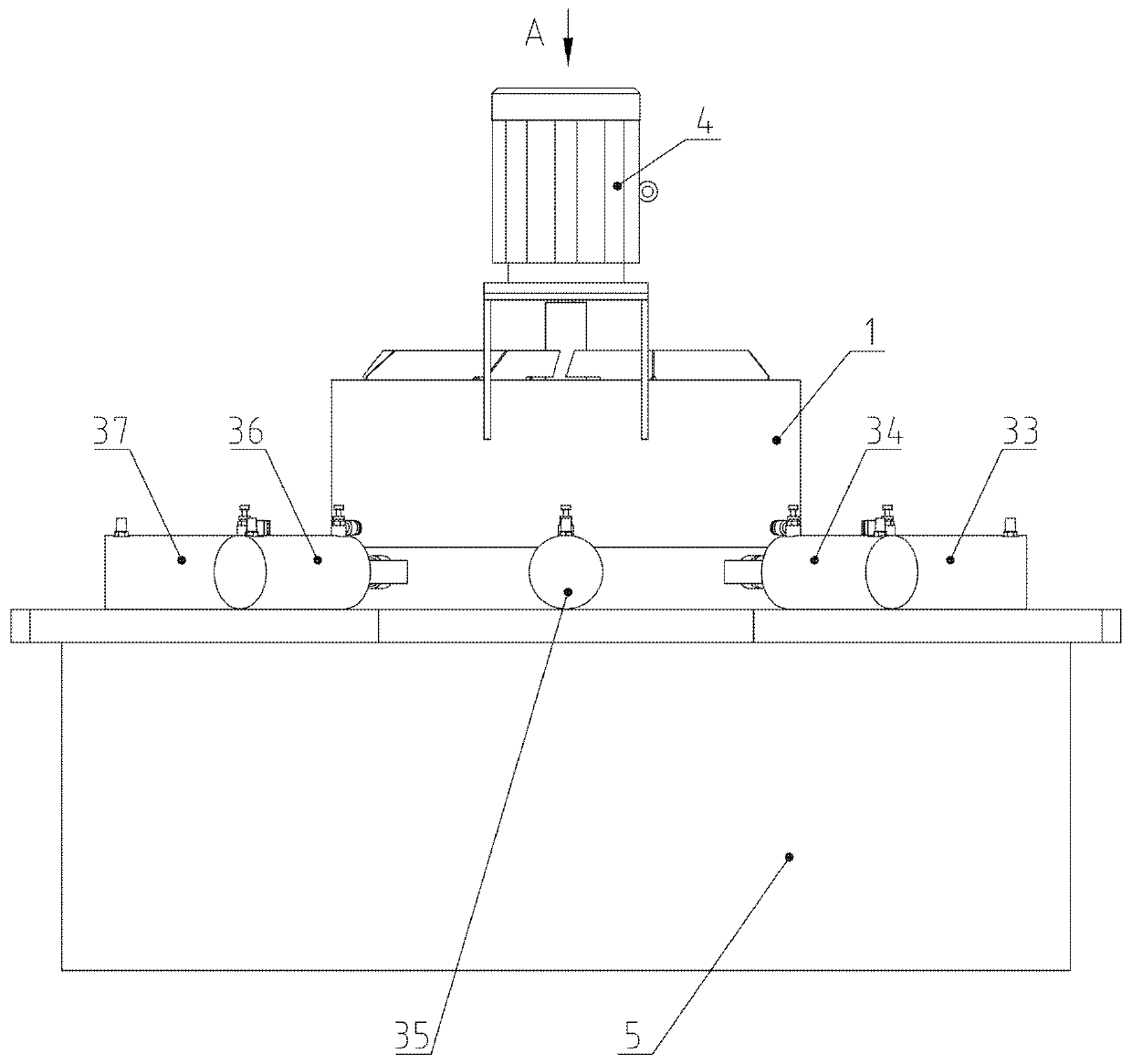

[0052] Example: see Figure 1 to Figure 13 .

[0053] A continuous automatic production equipment for spherical balls, including a bowl 1, an inner push rod 21, an inner push rod 22, an inner push rod 23, an inner push rod 424, an inner push rod 5 25, Push rod 626, inner push rod 727, inner push rod 828, passive cylinder one 31, passive cylinder two 32, passive cylinder three 33, passive cylinder four 34, passive cylinder five 35, passive cylinder six 36, Passive cylinder seven 37, passive cylinder eight 38, drive system 4, oil pan 5, internal push spring one 61, internal push spring two 62, internal push spring three 63, internal push spring four 64, internal push spring five 65, internal push Spring six 66, internal push spring seven 67, internal push spring eight 68;

[0054] The material bowl 1 includes an annular outer ring barrel 11, an annular inner ring core 12 and an annular bottom 13, the outer ring barrel 11 is sleeved around the inner ring core 12, and the annular bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com