Processing device for filtering film

A processing device and filter membrane technology, which is applied to the surface coating device and coating, can solve problems such as adhesion, uneven film surface, low efficiency, etc., and achieve smooth surface of rolled film products, improve quality and reduce The effect of the likelihood of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

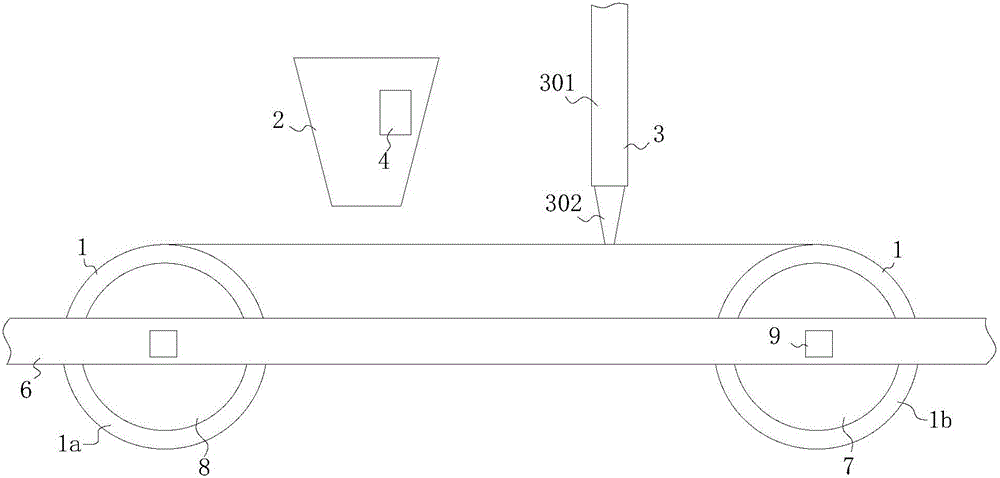

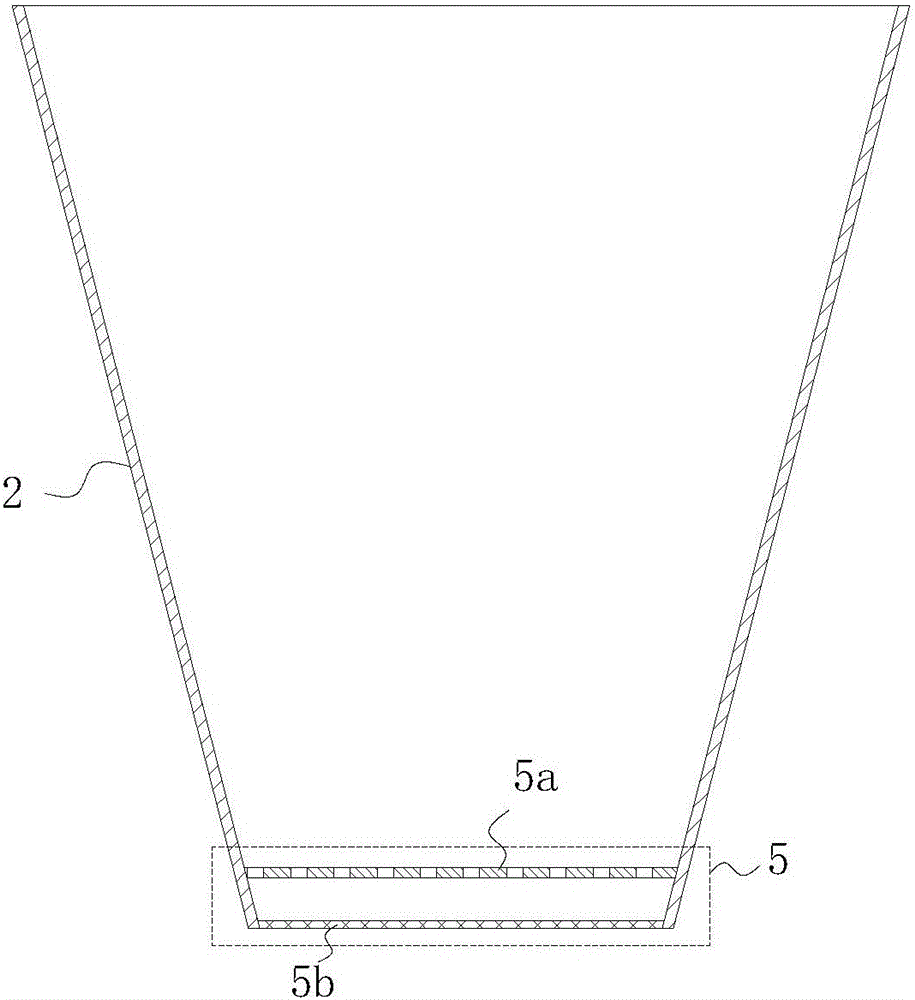

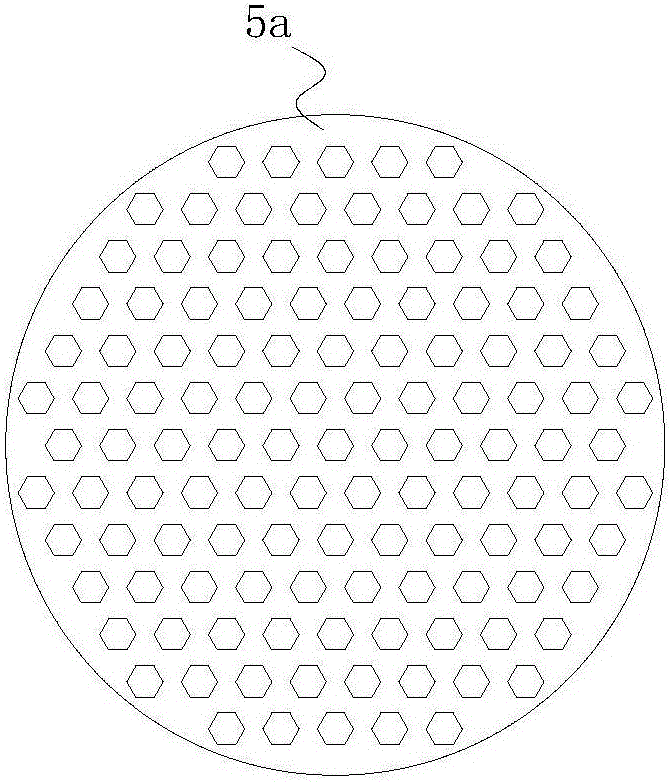

[0031] Embodiment one: if Figure 1-3 , a filter membrane processing device, this processing device is a device for processing a flexible porous metal foil filter membrane, the processing device includes a transfer device that flattens the filter membrane and moves the filter membrane and brushes the surface of the filter membrane with alumina powder The smearing device, the transfer device includes two adjacent spacing adjustable first reel 1a and second reel 1b, relative to the direction in which the filter membrane moves, the first reel 1a is arranged at the front end of the direction , the second reel 1b is arranged at the rear end in this direction, and the filter membrane is tensioned by the first reel 1a and the second reel 1b on the transfer device and is arranged between the transfer device and the smearing device; the smearing device It includes a paint funnel 2 and a brusher 3, the paint funnel 2 is arranged above the front end of the transfer device relative to the...

Embodiment 2

[0038] Embodiment two: if Figure 4 , different from Embodiment 1, the transfer device includes two adjacent first reel 1a and second reel 1b with adjustable spacing, a support body 10, a driving shaft 7 and a transmission shaft 8, and the support body 10 As a telescopic structure, the drive shaft 7 and the transmission shaft 8 are both arranged on the support body 10 .

[0039] Setting the reel 1 on the telescopic support body 10 is a way to conveniently adjust the distance between the reel 1 . After the size of the support body 10 is determined here, a locking device 9 is provided to keep the size of the support body 10 fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com