Liquid level monitoring and alarming device for washing liquid and waste liquid bottles of plate washing machine

A technology of liquid level monitoring and alarm device, which is applied in the direction of displaying liquid level indicators through pressure measurement, which can solve the problems that cannot be reflected in real time, and the waste liquid bottle has no liquid level detection, so as to prevent laboratory pollution and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

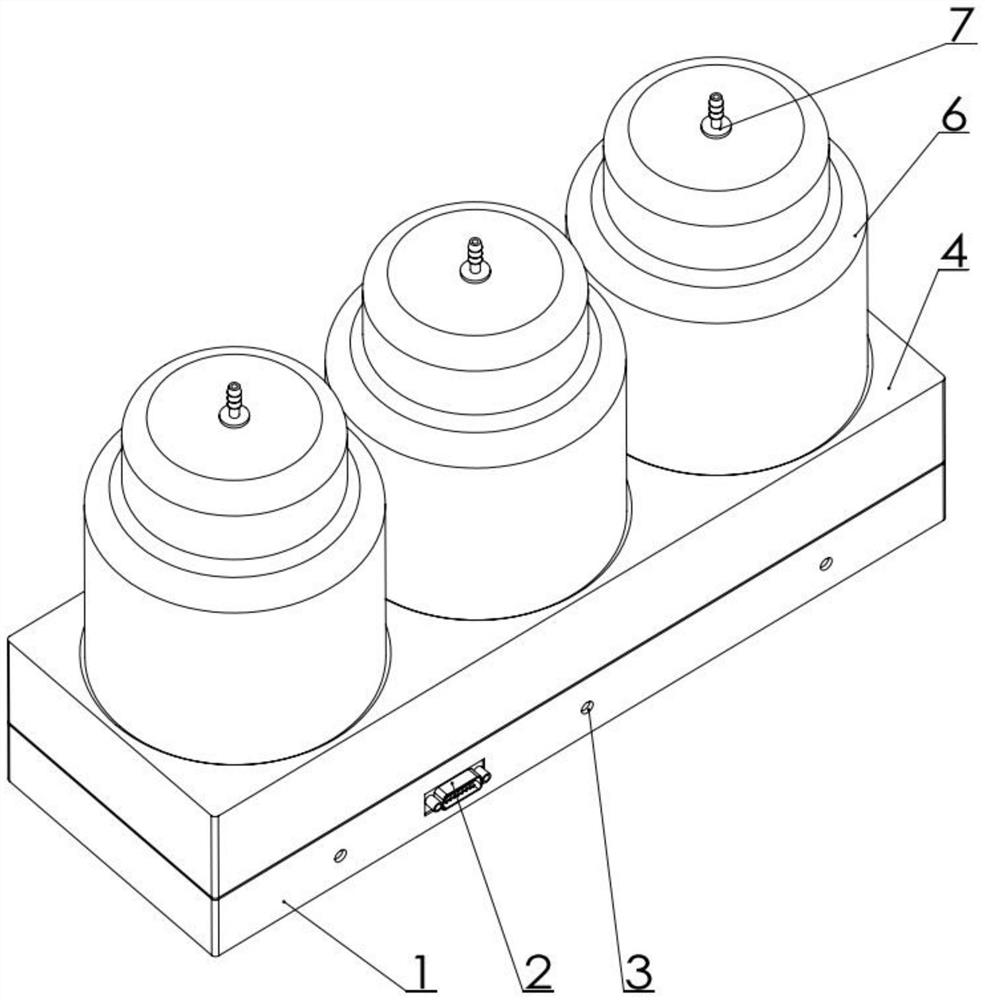

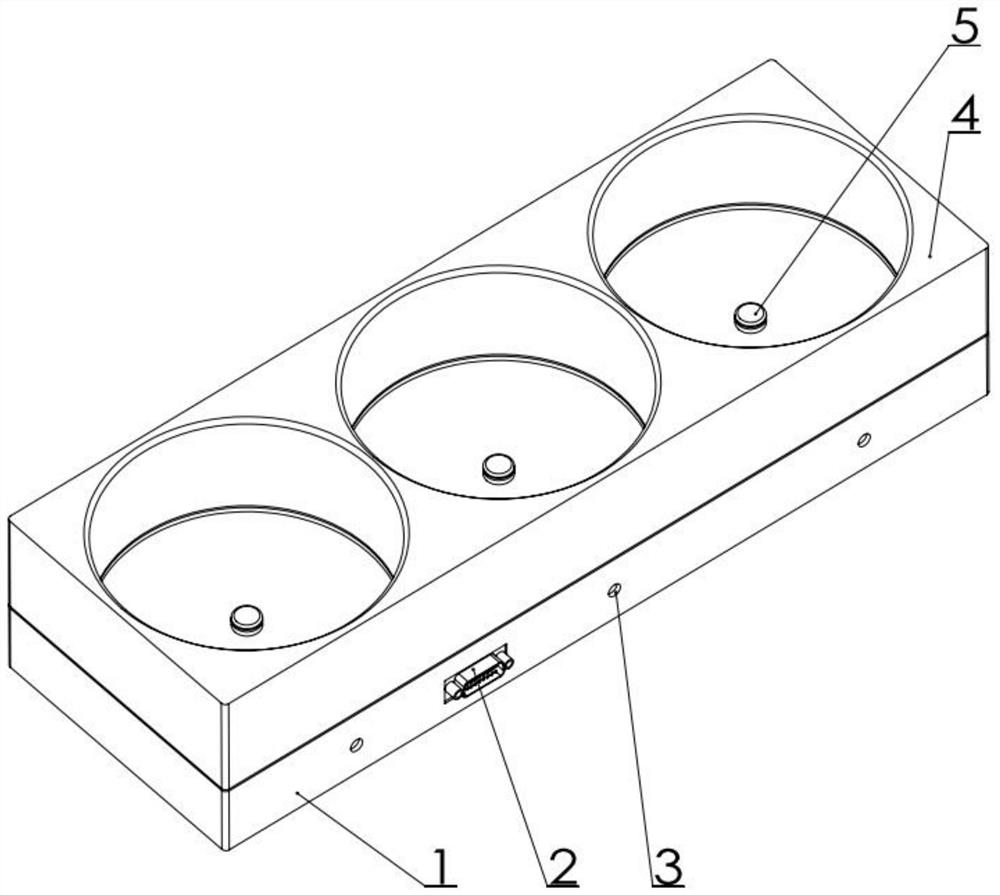

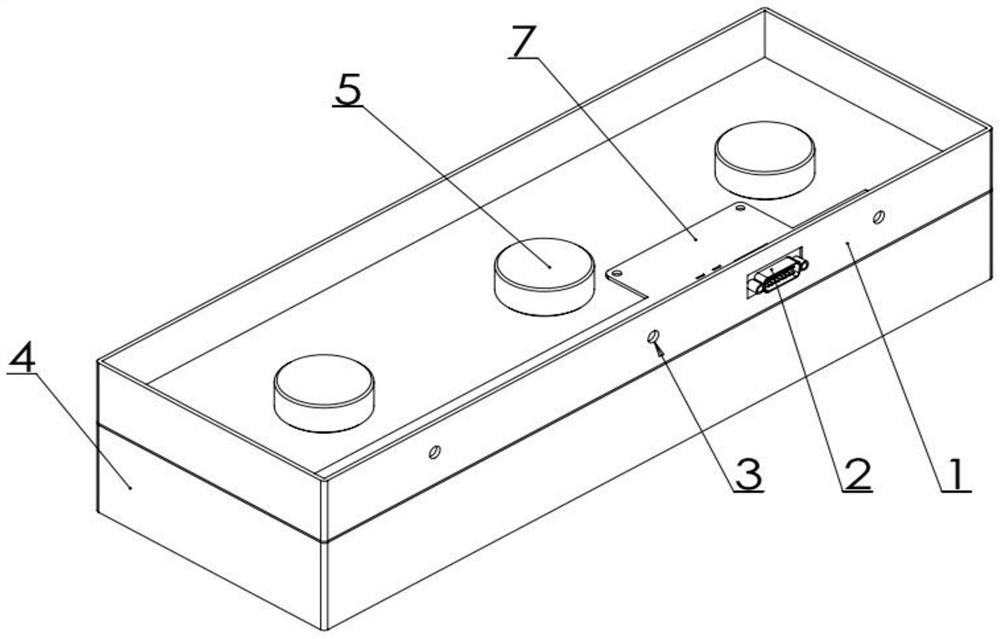

[0020] The invention discloses a liquid level monitoring and alarm device for washing liquid and waste liquid bottle of a plate washing machine, such as Figures 1 to 3 As shown, it includes a bottom shell 1 and a lotion bottle seat 4, the lotion bottle seat 4 is fixedly arranged on the upper surface of the bottom shell 1, and the surface of the lotion bottle seat 4 is provided with several circular through holes, and the bottom shell 1 is provided with a number of press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap