A lithium battery charging circuit and pcb board

A charging circuit and lithium battery technology, which is applied in battery circuit devices, circuit devices, battery overheating protection, etc., can solve problems such as easy tripping, failure to meet fast charging requirements, excessive transient current, etc., and achieve power-on tripping problems, avoiding battery overheating and burning, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention provides a lithium battery charging circuit and a PCB board. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0031] In the description of the present invention, it should be understood that the terms "installation" and "connection" should be understood in a broad sense, and those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention according to specific situations.

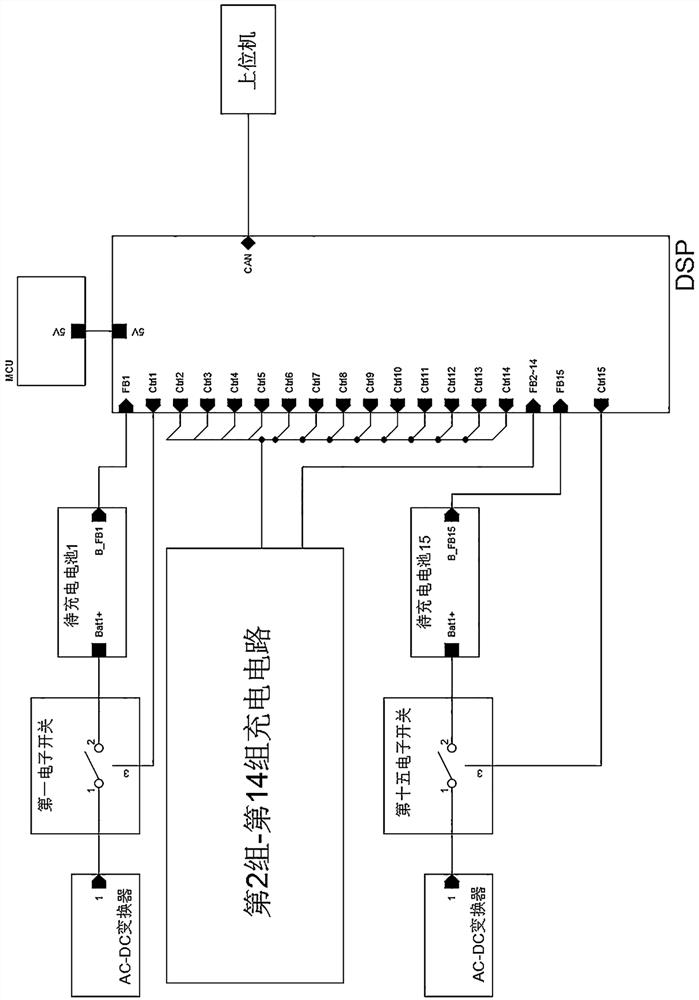

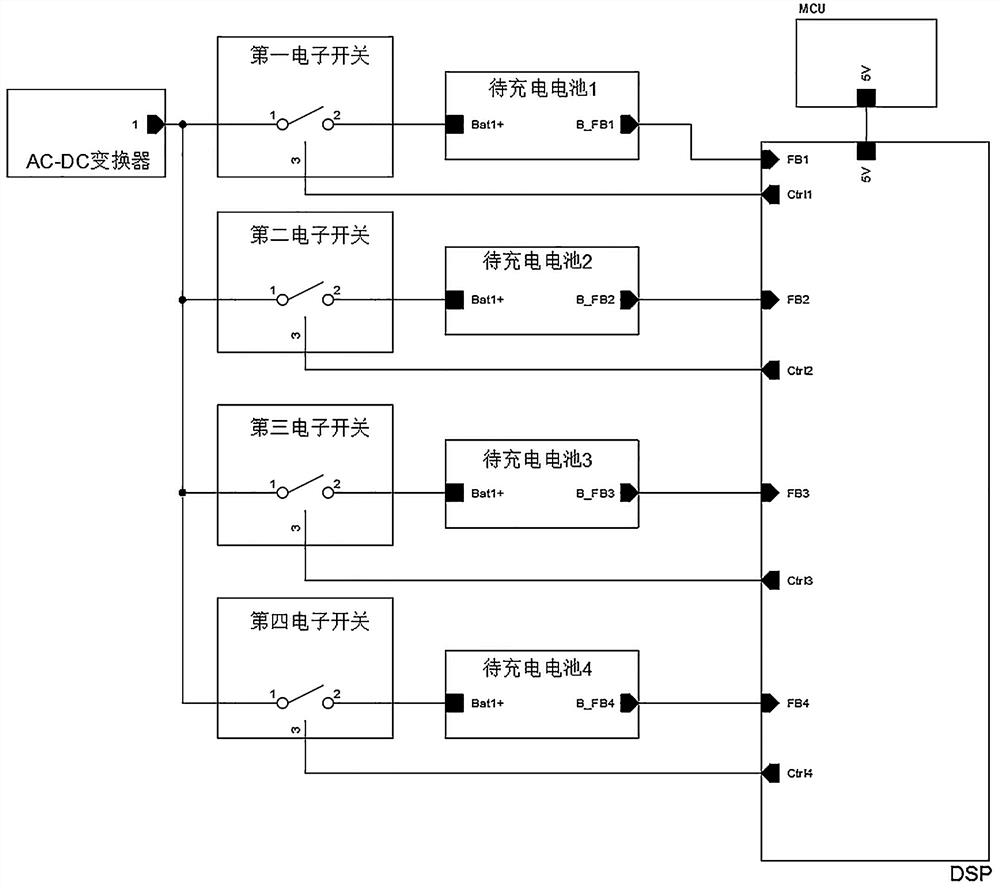

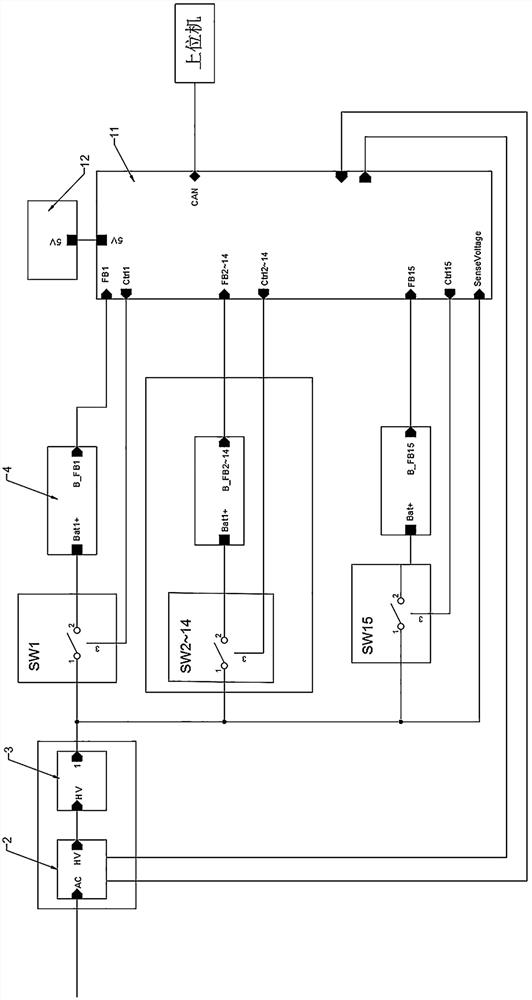

[0032] see Figure 3 to Figure 6 , the present invention provides a lithium battery charging circuit, including a power factor correction unit 2 for power factor adjustment, a DC-DC converter 3, an electronic switch, a battery pack to be charged 4 and a processing unit, the electronic switch The number is consistent with the number of battery pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com