Ventilation and heat dissipation device for mask

A technology for ventilation and heat dissipation, masks, applied in clothing, applications, clothing and other directions, can solve the problems of reduced virus protection ability, unfavorable epidemic prevention and control work, poor versatility and interchangeability, etc., to improve the versatility and interchangeability, Reduce the chance of soaking the mask and ensure the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

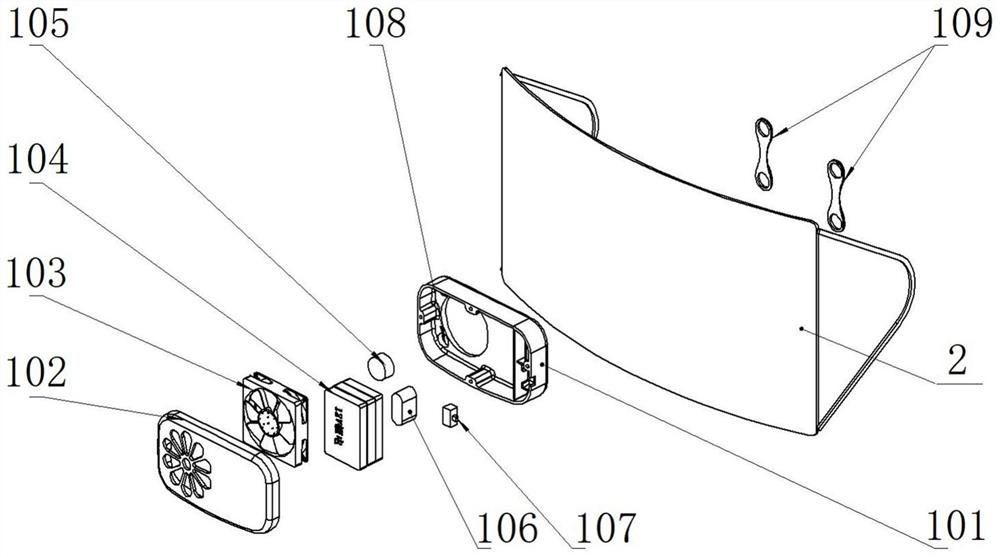

[0049] figure 1 Shown is the structure of the ventilating and cooling device for masks according to Embodiment 1 of the present invention.

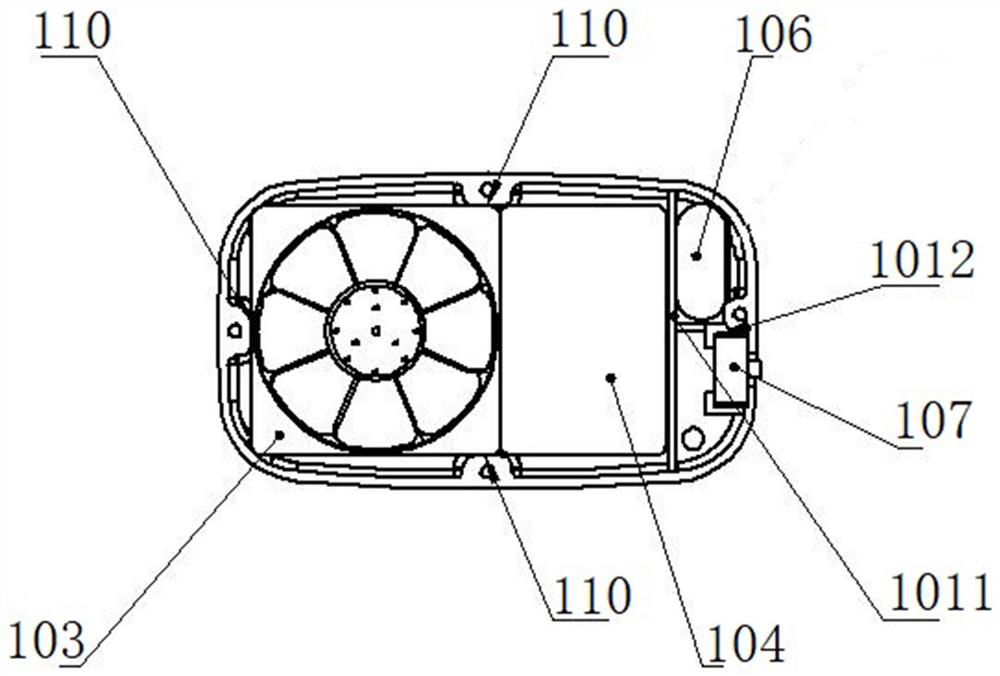

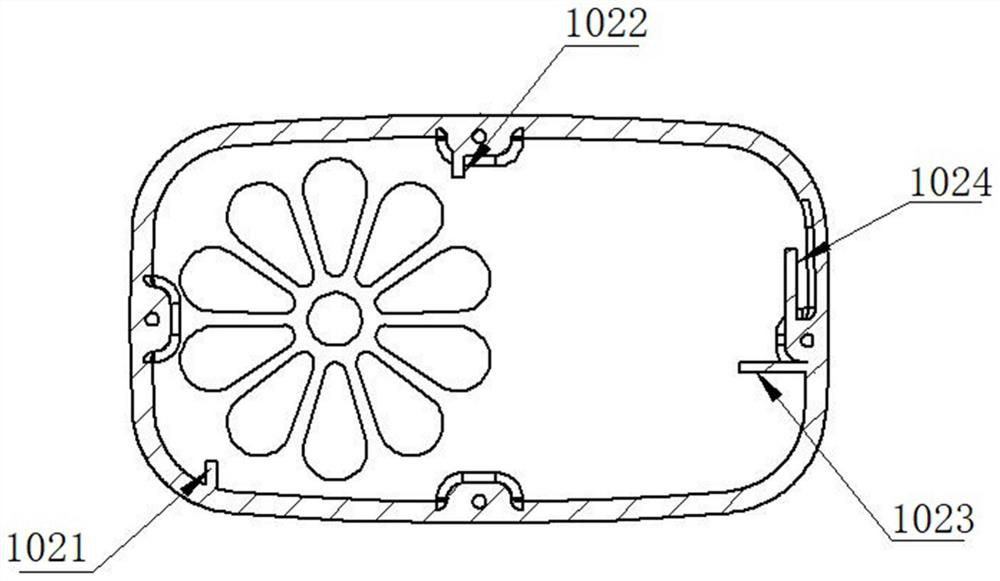

[0050] Such as figure 1As shown, the ventilation and heat dissipation device for a mask provided by Embodiment 1 of the present invention includes: a housing base 101, a housing upper cover 102, a miniature cooling fan 103, a DC power supply 104, a temperature sensor 105, a control module 106, a toggle switch 107 and The detachable locking structure installs the miniature heat dissipation fan 103, the DC power supply 104, the temperature sensor 105, the control module 106 and the toggle switch 107 respectively in the shell base 101, and the shell upper cover 102 is covered on the shell base 101. To fix the components inside the housing base 101 , the detachable locking structure is used to detachably fix the housing base 101 on the mask 2 .

[0051] Miniature radiating fan 103 is a small direct current fan, is used for producing the air...

Embodiment 2

[0100] The difference between embodiment 2 and embodiment 1 is that the structure of the detachable locking structure is different, other structures are the same as embodiment 1, and the speed adjustment method of the miniature cooling fan is also the same.

[0101] The detachable locking structure in embodiment 2 includes two straps, one end of the two straps is respectively tied to the two sides of the housing base, and the other ends of the two straps are buckles or Velcro respectively.

[0102] When using the ventilation and heat dissipation device for masks, wrap the buckle or Velcro end of the strap to the back of the head, then fasten the buckle or stick the Velcro to make the mask be fixed on the face with the ventilation and heat dissipation device and stick to the mask .

Embodiment 3

[0104] The difference between embodiment 3 and embodiment 1 is that the structure of the detachable locking structure is different, other structures are the same as embodiment 1, and the speed adjustment method of the miniature cooling fan is also the same.

[0105] The detachable locking structure in embodiment 3 includes a fixed card and a card slot. The card slot is opened on the outer wall of the shell base facing the mask, and the fixed card is pasted on the outside of the mask with glue.

[0106] When using the ventilation and heat dissipation device for the mask, the fixing card is snapped into the card slot, so that the ventilation and heat dissipation device for the mask is fixed on the mask.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com