Intelligent tableware cleaning system and working method thereof

A cleaning system and smart tableware technology, applied in cleaning equipment, cleaning devices, household cleaning devices, etc., can solve problems such as reducing labor costs, achieve the effects of reducing labor costs, saving manpower, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

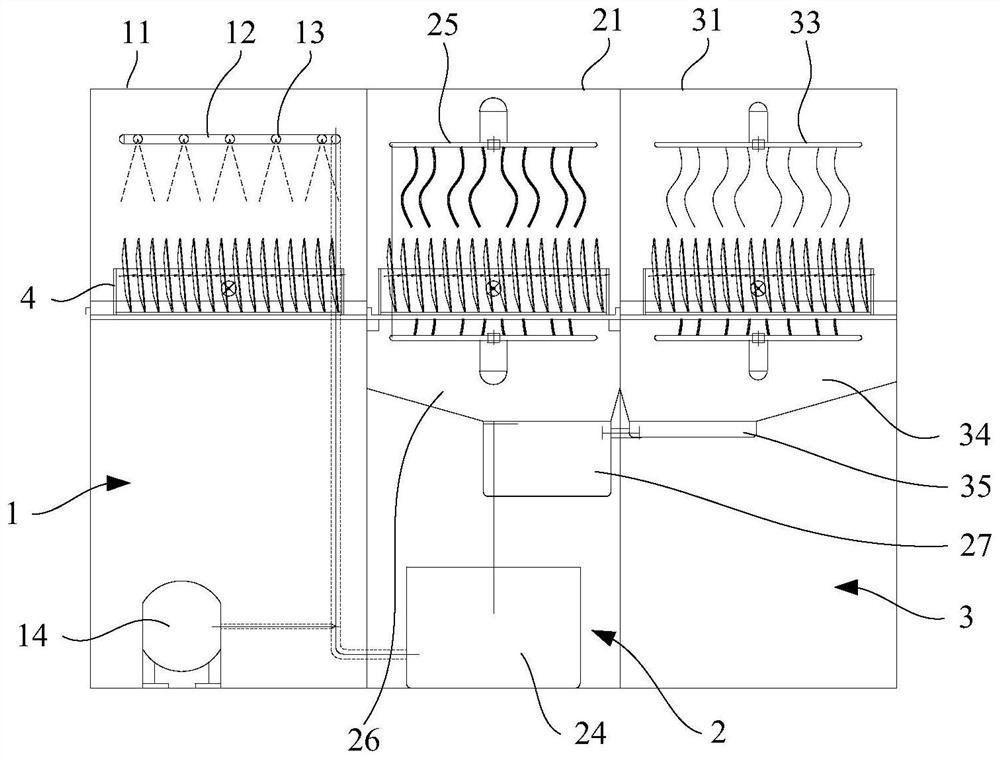

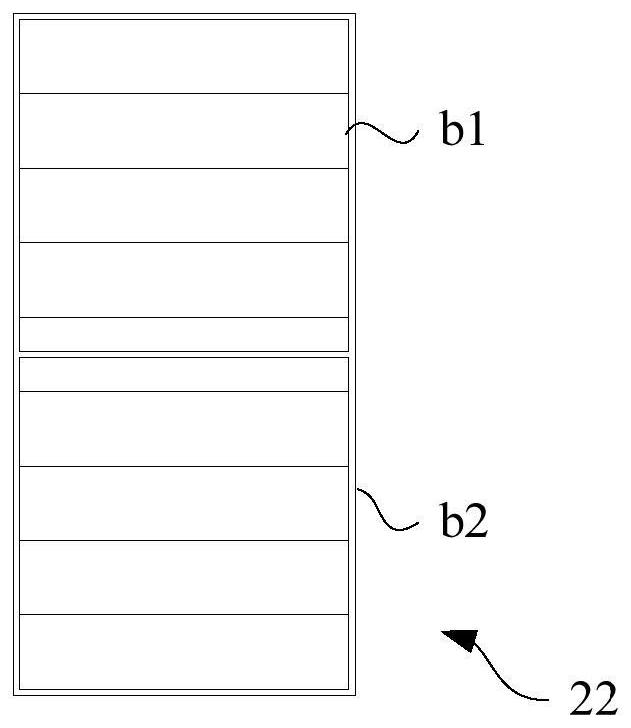

[0042] see figure 1 As shown, the embodiment of the present application provides a kind of intelligent tableware cleaning system, comprises:

[0043] Slag removal device 1 is used for removing slag from tableware to be cleaned;

[0044] The main washing device 2 is used to clean the tableware after deslagging;

[0045] The rinsing device 3 is used for rinsing the washed tableware

[0046]The conveying device passes through the main washing device 2 via the scum removing device 1 and extends to the rinsing device 3 , and is used to transport the tableware to be treated to the scum removing device 1 , the main washing device 2 and the rinsing device 3 in sequence.

[0047] The working principle of the intelligent tableware cleaning system is as follows:

[0048] The conveying device first conveys the tableware to be cleaned to the slag removal device 1 (note here, the tableware to be cleaned can be placed in the carrying basket 4 as described below, and then the conveying dev...

Embodiment 2

[0067] Embodiments of the present application also provide a working method of an intelligent tableware cleaning system, including the intelligent tableware cleaning system described in any one of the above embodiments, thus having all the beneficial technical effects of the device, which will not be repeated here.

[0068] In this embodiment, preferably, the working method of the intelligent tableware cleaning system includes the following steps:

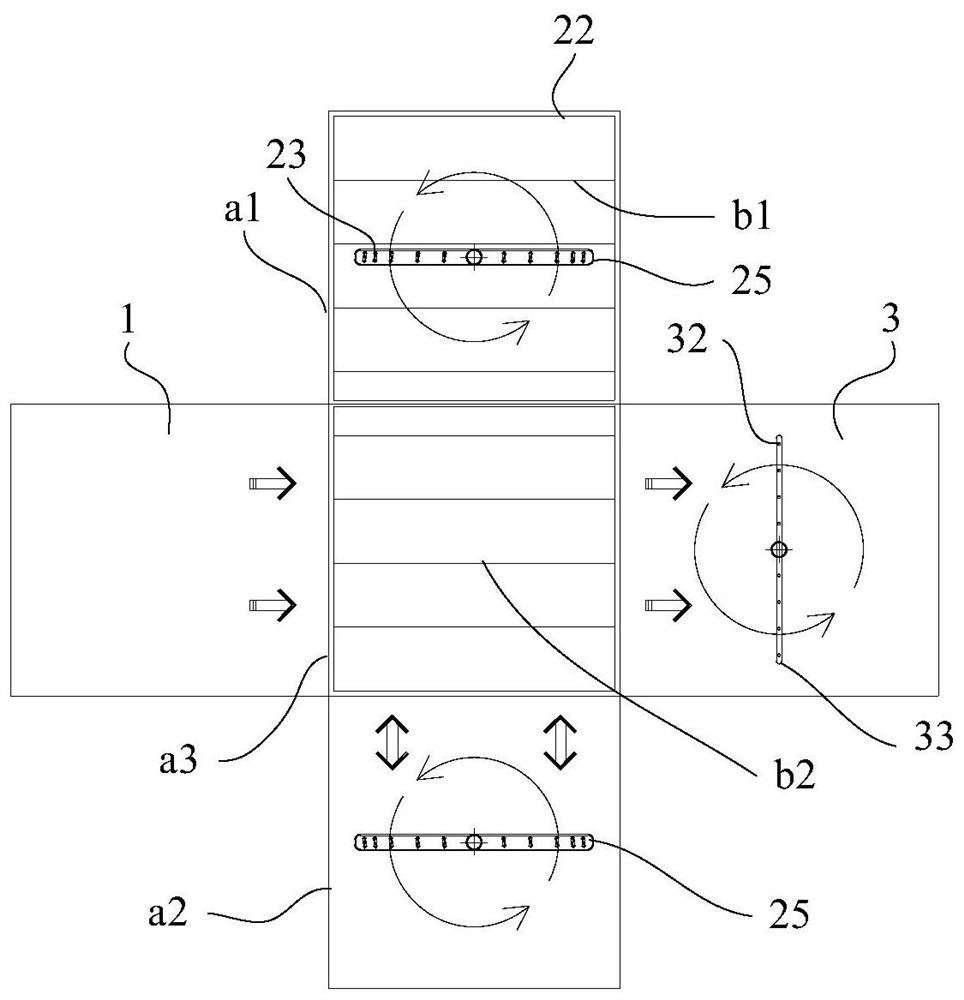

[0069] The first batch of tableware first enters the slag removal device 1 for deslagging treatment, and the first batch of tableware after the slag removal is completed enters the first main washing station a1 through the transfer station a3 for main washing. In the state of main washing, the second batch of tableware is deslagging, and after the deslagging is completed, it is sent to the transfer station a3;

[0070] After the main washing of the first batch of tableware is completed, the second batch of tableware is sent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com